An integrated coal gasification fuel cell power generation system and method utilizing high temperature sensible heat of coal gas

An integrated coal gasification and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as loss of power generation capacity, and achieve the effects of reducing volume, easy sequential startup, and simplifying system processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

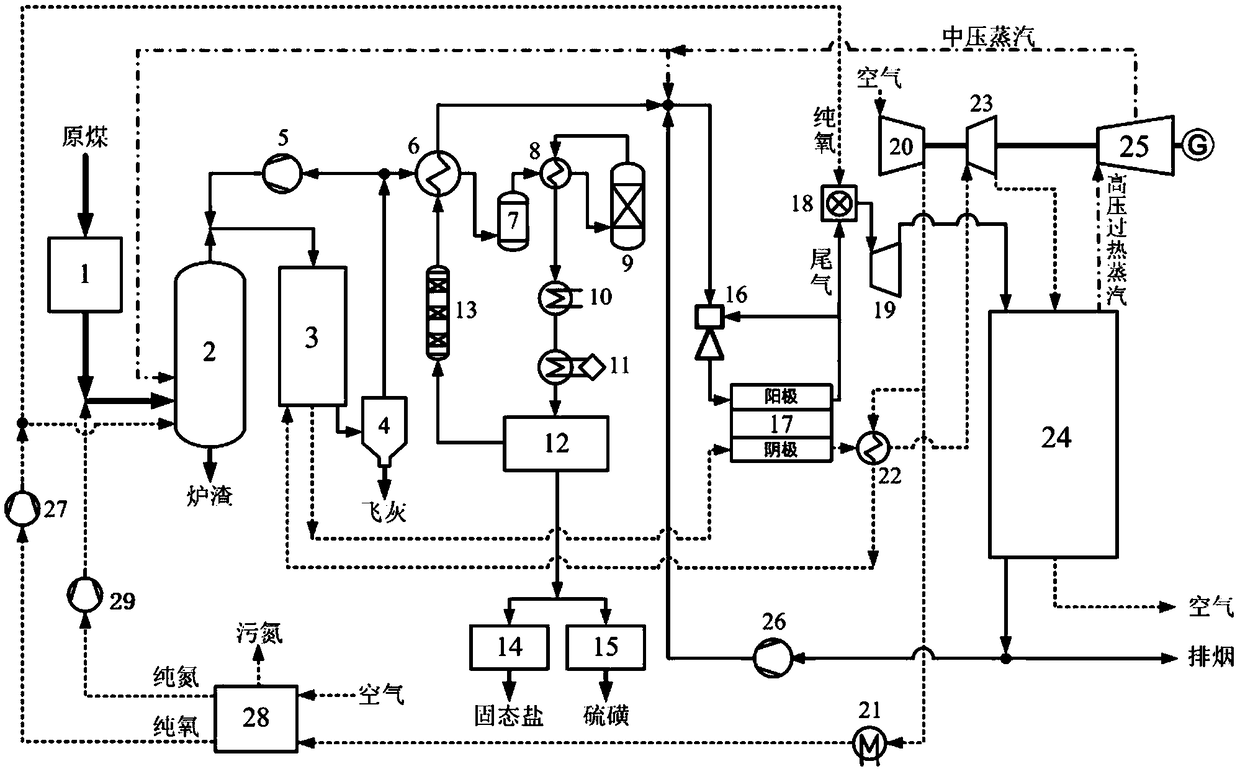

[0041] Embodiment 1: Utilize high temperature sensible heat of coal gas to heat cathode air

[0042] see figure 1 As shown, the present invention is an integrated coal gasification fuel cell power generation system utilizing high temperature sensible heat of coal gas. The system flow is as follows:

[0043] The raw coal is pulverized and dried in the coal preparation unit 1 to form dry coal powder, and the high-pressure nitrogen at the outlet of the nitrogen compressor 29 is transported to the gasifier 2. The pressurized steam is sent to the gasification furnace 2 for reaction at the same time. The bottom of the gasification furnace 2 produces slag, and the high-temperature crude gas generated at the top is mixed with the low-temperature gas at the outlet of the circulating gas compressor 5. After being chilled, it is sent to the waste heat boiler 3; The heat released inside is used to heat the air exiting from the cold side of the cathode regenerator 22, and the heated air i...

Embodiment 2

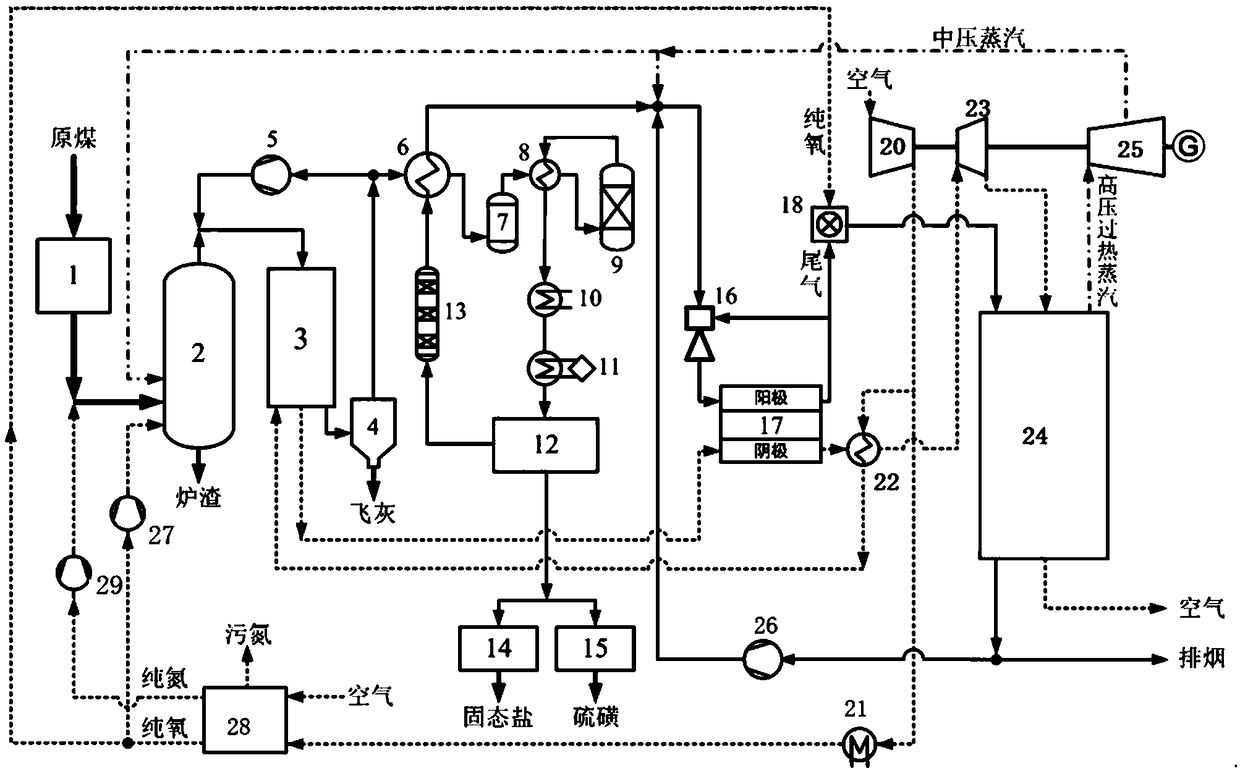

[0044] Embodiment 2: Utilize high temperature sensible heat of coal gas to heat cathode air

[0045] see figure 2 As shown, the present invention is an integrated coal gasification fuel cell power generation system utilizing high temperature sensible heat of coal gas. The system flow is as follows:

[0046] The raw coal is pulverized and dried in the coal preparation unit 1 to form dry coal powder, and the high-pressure nitrogen at the outlet of the nitrogen compressor 29 is transported to the gasifier 2. The pressurized steam is sent to the gasification furnace 2 for reaction at the same time. The bottom of the gasification furnace 2 produces slag, and the high-temperature crude gas generated at the top is mixed with the low-temperature gas at the outlet of the circulating gas compressor 5. After being chilled, it is sent to the waste heat boiler 3; The heat released inside is used to heat the air exiting from the cold side of the cathode regenerator 22, and the heated air ...

Embodiment 3

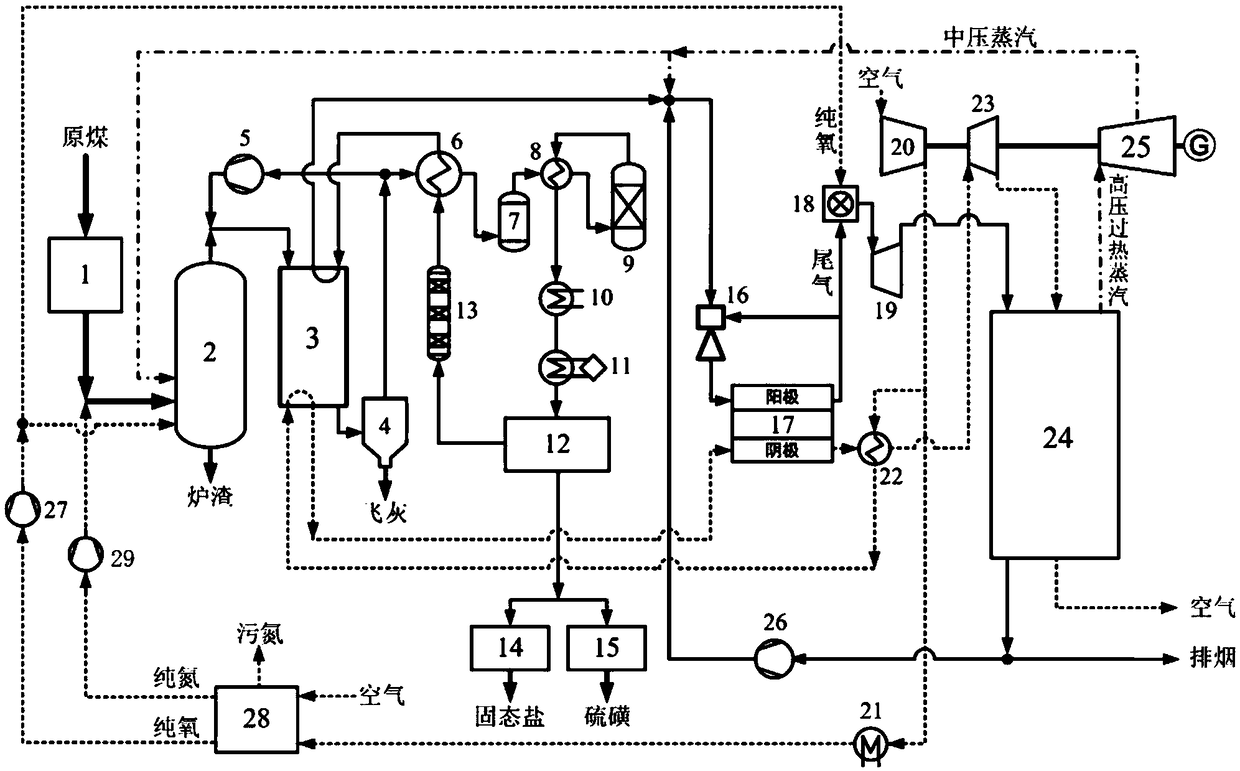

[0047] Embodiment 3: Utilize high temperature sensible heat of coal gas to heat cathode air and fuel gas

[0048] see image 3 As shown, the present invention is an integrated coal gasification fuel cell power generation system utilizing high temperature sensible heat of coal gas. The system flow is as follows:

[0049] The raw coal is pulverized and dried in the coal preparation unit 1 to form dry coal powder, and the high-pressure nitrogen at the outlet of the nitrogen compressor 29 is transported to the gasifier 2. The pressurized steam is sent to the gasification furnace 2 for reaction at the same time. The bottom of the gasification furnace 2 produces slag, and the high-temperature crude gas generated at the top is mixed with the low-temperature gas at the outlet of the circulating gas compressor 5. After being chilled, it is sent to the waste heat boiler 3; The heat released inside is used to heat the air exiting from the cold side of the cathode regenerator 22, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com