A control method for a hierarchical series cooling system of low-temperature thermal fluid

A cooling system control, low-temperature heat technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as limiting the scope of application, and achieve the effect of expanding the scope of application, reducing initial investment, and improving net power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

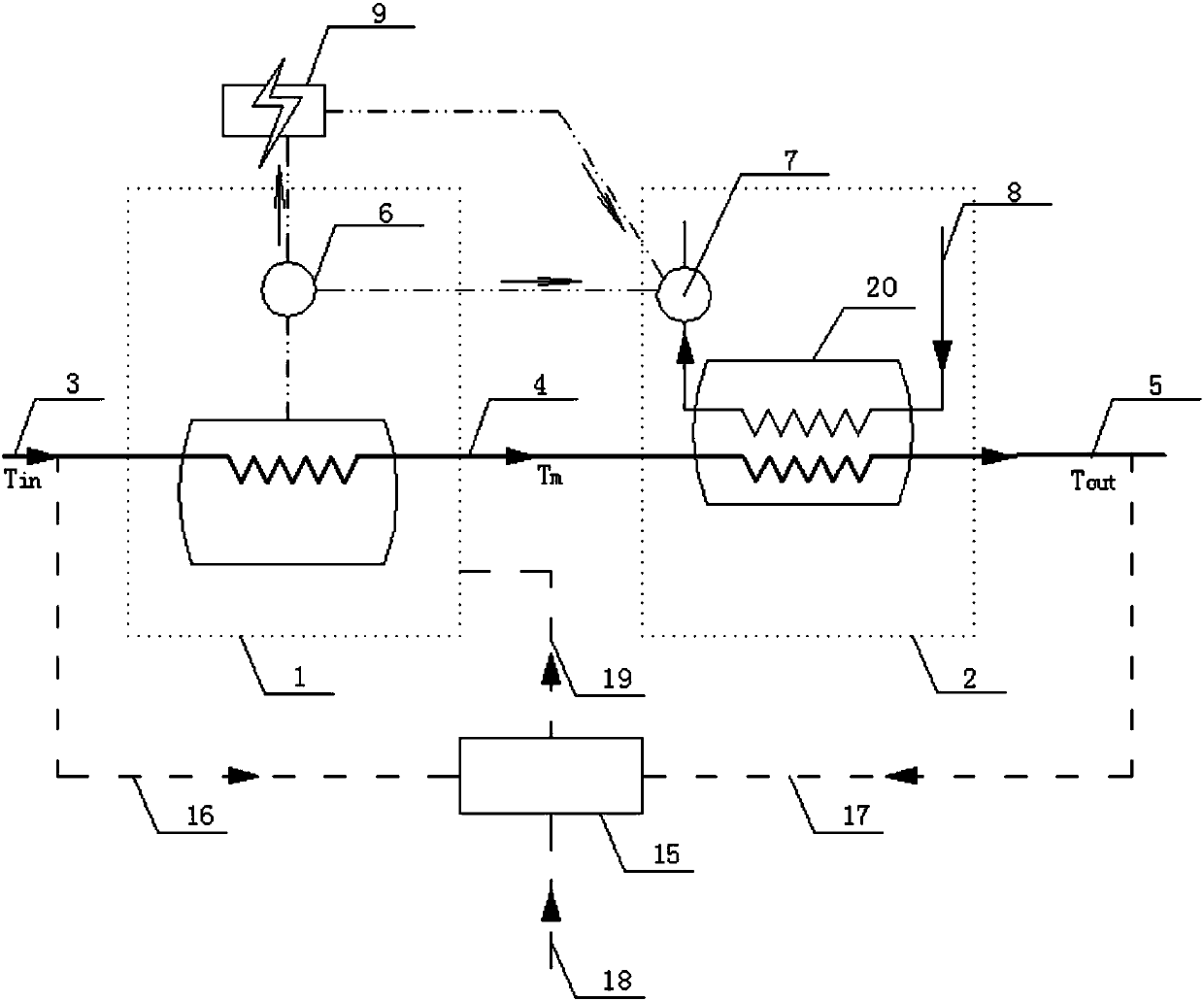

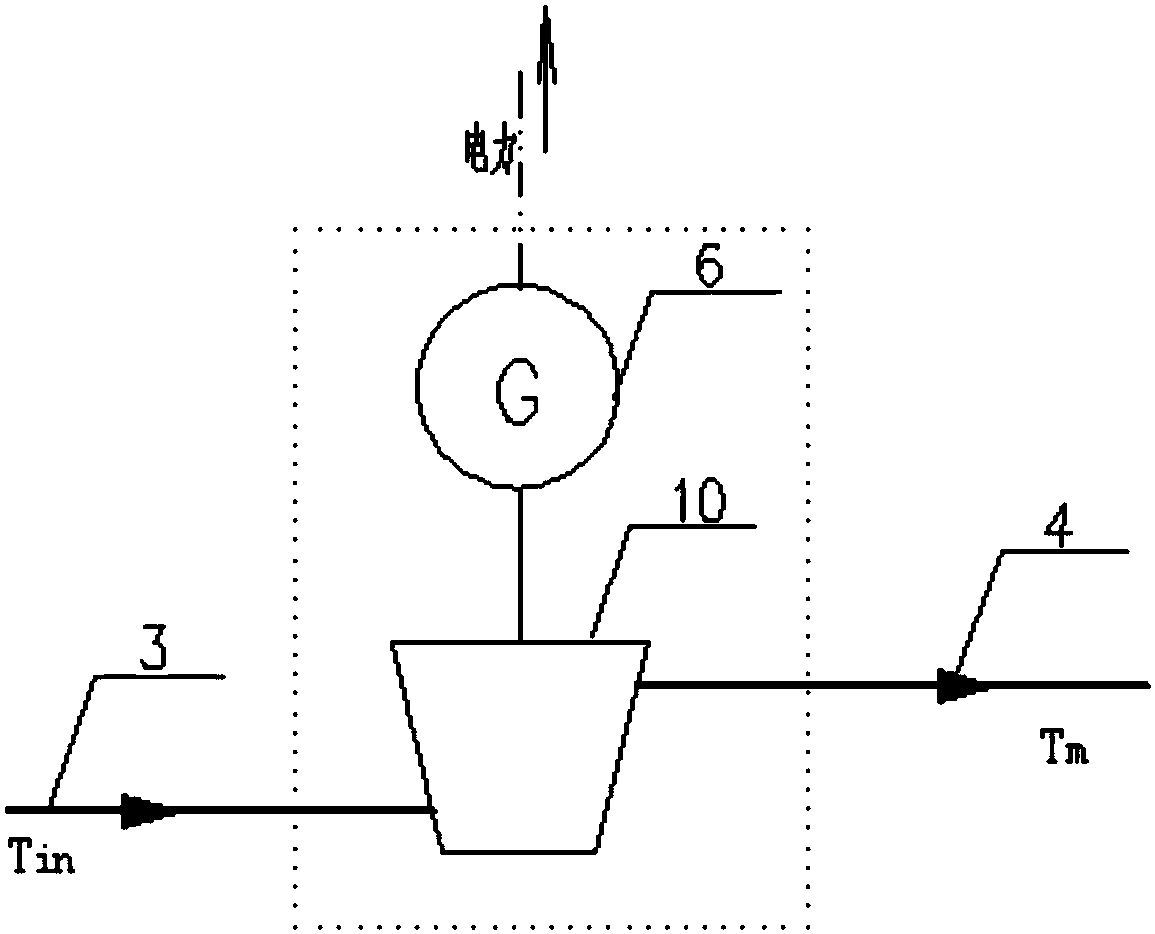

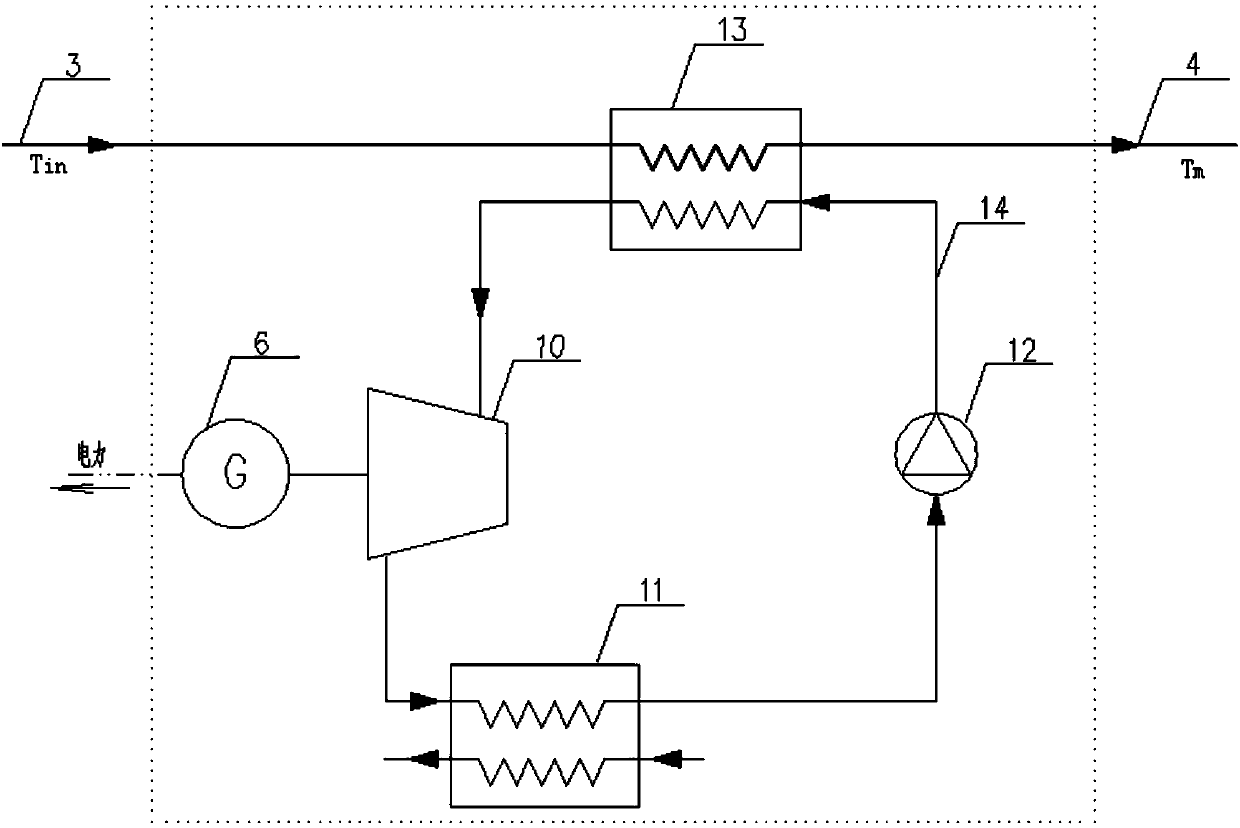

[0026] Such as Figure 1 to Figure 5 As shown, a hierarchical series cooling system of low-temperature thermal fluid, the system includes two-stage cooling units arranged in series, wherein the first-stage cooling unit is a power generation cooling unit 1, and the second-stage cooling unit is a conventional cooling unit 2; the inlet temperature is T in The thermal fluid 3 first enters the power generation cooling unit 1 and is cooled to a suitable intermediate temperature T m ; Power generation cooling unit 1 is cooled to an intermediate temperature of T m The thermal fluid 4 then enters the conventional cooling unit 2 and is finally cooled to the target outlet temperature T out , that is, the target outlet temperature is T out thermal fluid 5.

[0027] Preferably, the conventional cooling unit 2 includes a power device 7 (pump, fan, etc.) and a conventional cooling device 20: an air cooling device, a water cooling device, an evaporative cooling device, and a composite coo...

Embodiment 2

[0034] On the basis of the first embodiment, the present invention also includes a control unit 15, which is respectively connected to the power generation cooling unit 1 and the conventional cooling unit 2, and the control unit 15 is used to control the cooling capacity of each cooling unit.

[0035] Preferably, the intermediate temperature T m According to the optimal control target, combined with the process conditions and local meteorological conditions, the control unit 15 adopts the optimization algorithm to carry out reasonable setting and real-time adjustment, so as to realize the dynamic distribution of the cooling capacity undertaken by the two-stage cooling system, so that the hierarchical series cooling system as a whole is real-time in optimal operating condition.

[0036] Preferably, the control process of the control unit 15 of the hierarchical series cooling system is as follows: Step (1): The control unit 15 monitors and collects the inlet temperature T of the...

example

[0037] Example: For a coal-to-oil transformation process, the process heat fluid to be cooled is hot water, the flow rate is 6000t / h, the initial temperature of the hot water is 90°C, the target temperature required to be cooled is 40°C, and the local annual average ambient temperature is 15 ℃.

[0038] The energy consumption or production energy of the air cooling mode, the evaporative cooling mode, the power generation cooling mode and the hierarchical series cooling system of a low-temperature thermal fluid of the present invention are respectively calculated to further illustrate the effect of the present invention.

[0039] (1) Cooling load

[0040] The cooling load of the thermal fluid in this coal-to-oil conversion process can be calculated according to formula (1), and the calculation result of this example is 350000kW.

[0041] Q=c·m·Δt (1)

[0042] Among them, Q is the cooling load of the process thermal fluid (kW), c is the specific heat capacity of the process th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com