Coal catalytic gasification method

A technology of coal catalytic gasification and carbon monoxide, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of reducing carbon conversion rate, no economic advantages, reducing methane yield, etc., and achieves improved conversion rate and good technical economy. , the effect of improving the yield of methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

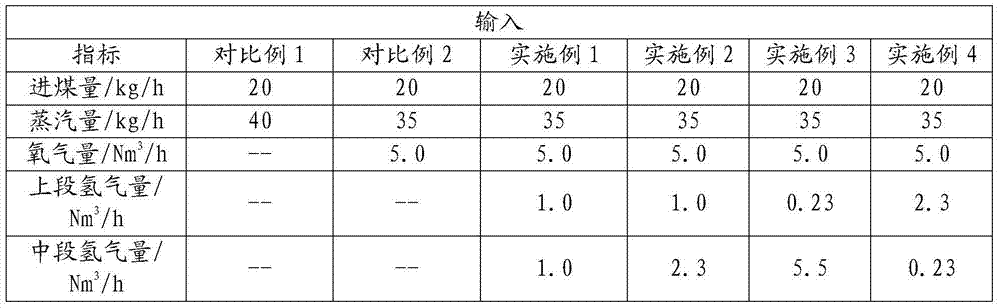

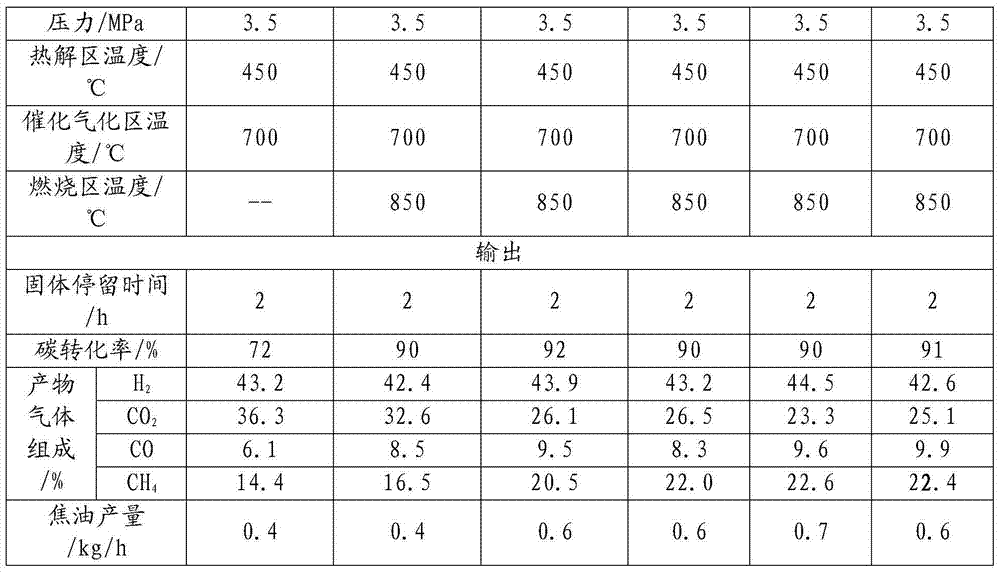

Embodiment 1

[0048] Embodiment 1 is to pass into 1Nm respectively in the reactor body upper section and the middle section 3 / h hydrogen (corresponding to the mass ratio of hydrogen to coal is 0.0046:1), the experimental results show that the carbon conversion rate is 92%, the methane gas composition is increased to 20.5%, and the tar yield is increased to 0.6kg / h.

Embodiment 2

[0049] Embodiment 2 Change the amount of hydrogen in the middle section, and increase the amount of hydrogen to 2.3Nm 3 / h ((corresponding to the mass ratio of hydrogen and coal is 0.01:1), the experimental results show that the carbon conversion rate is 90%, slightly lower than that of Example 1, the methane gas composition is increased to 22.0%, and the tar yield is 0.6kg / h .

Embodiment 3

[0050] Embodiment 3 is to pass into 0.23Nm in the reactor body upper section 3 / h hydrogen (corresponding to the mass ratio of hydrogen to coal is 0.001:1), and 5.6Nm3 / h hydrogen is introduced into the middle section (corresponding to the mass ratio of hydrogen to coal is 0.025:1). The experimental results show that the carbon conversion rate is 90%, methane The gas composition was 22.6%, and the tar yield was 0.7kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com