Production and mooring system for sea floating type oil extraction platform and operating method thereof

A technology of oil production platform and mooring system, which is applied in the direction of production fluid, earth drilling, floating buildings, etc., can solve the problems of difficult and reasonable layout of production system in water, achieve significant technical economy, reduce production cost, and optimize layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

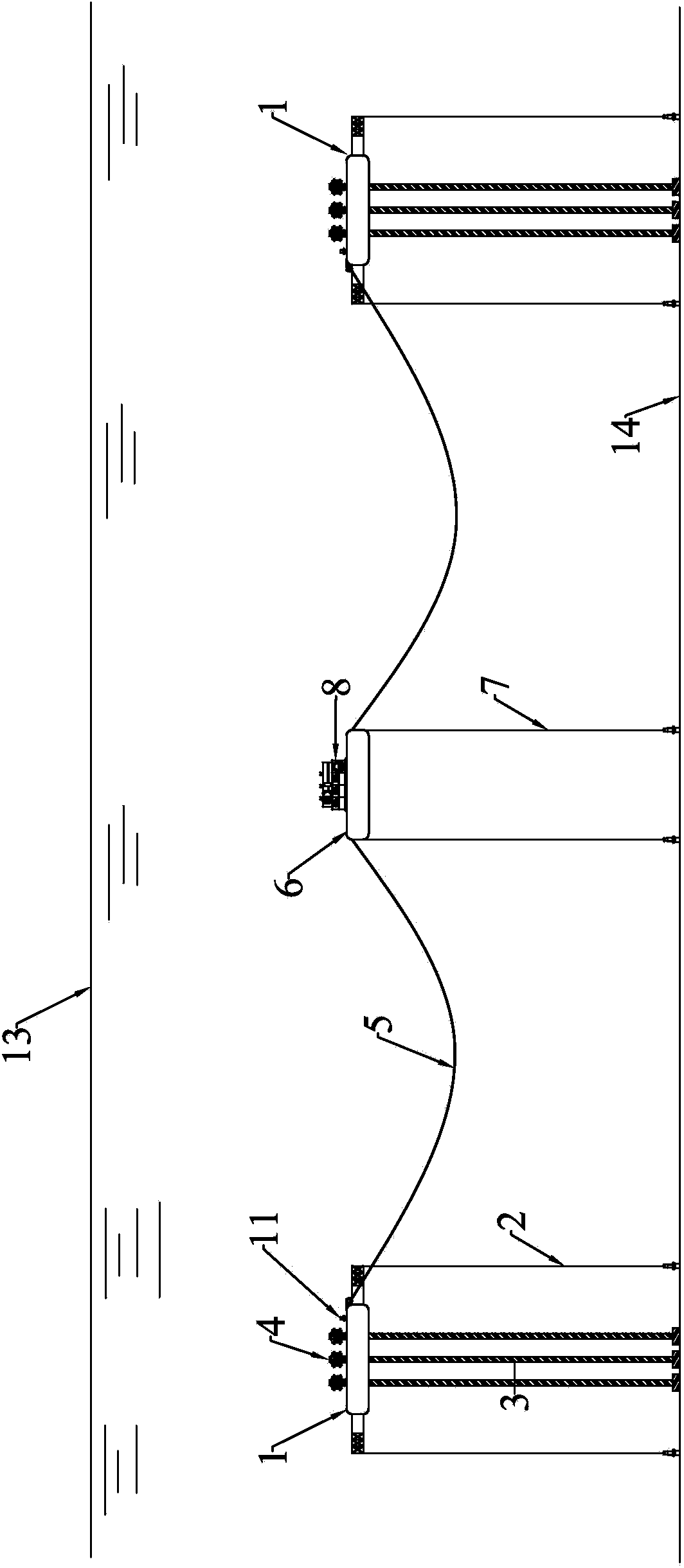

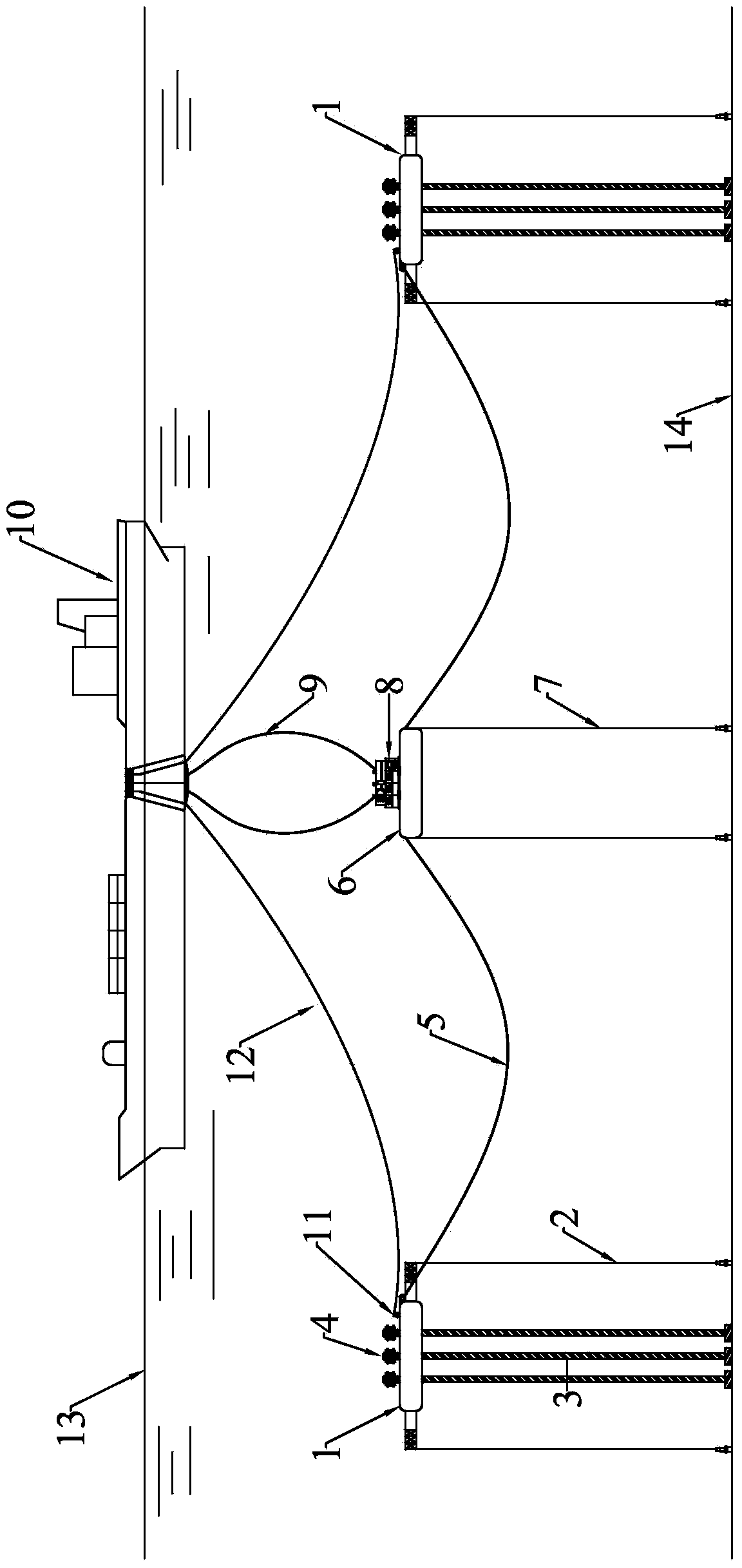

[0024] Such as figure 1 As shown, a production and mooring system of a floating oil production platform on the sea surface includes a water production platform 1, a manifold platform 6, a water production equipment 4, a manifold center 8, a rigid riser 3, a cable A2, a cable B7 and a flexible span Take over 5. Both the underwater oil production platform 1 and the manifold platform 6 are located 50-300 meters below the sea level 13, so as to avoid the influence of huge wind and waves on the sea surface. The underwater oil production platform 1 and the manifold platform 6 are tension moored on the seabed 14 through the cables A2 and B7 respectively. The underwater oil production platform 1 is used to support the rigid riser 3 and the underwater oil production equipment 4 , and the manifold platform 6 is used to support the manifold center 8 . The underwater oil produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com