PC decarbonization process PC liquid pressure energy recovery method and device

A carbon-propylene decarburization method carbon-propylene liquid and recovery method technology, which is applied to household refrigeration devices, compressors, refrigeration and liquefaction, etc., can solve problems such as waste of carbon-propylene liquid pressure potential energy, and achieves reduction of carbon-propylene liquid loss and system. The effect of simplifying the process and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

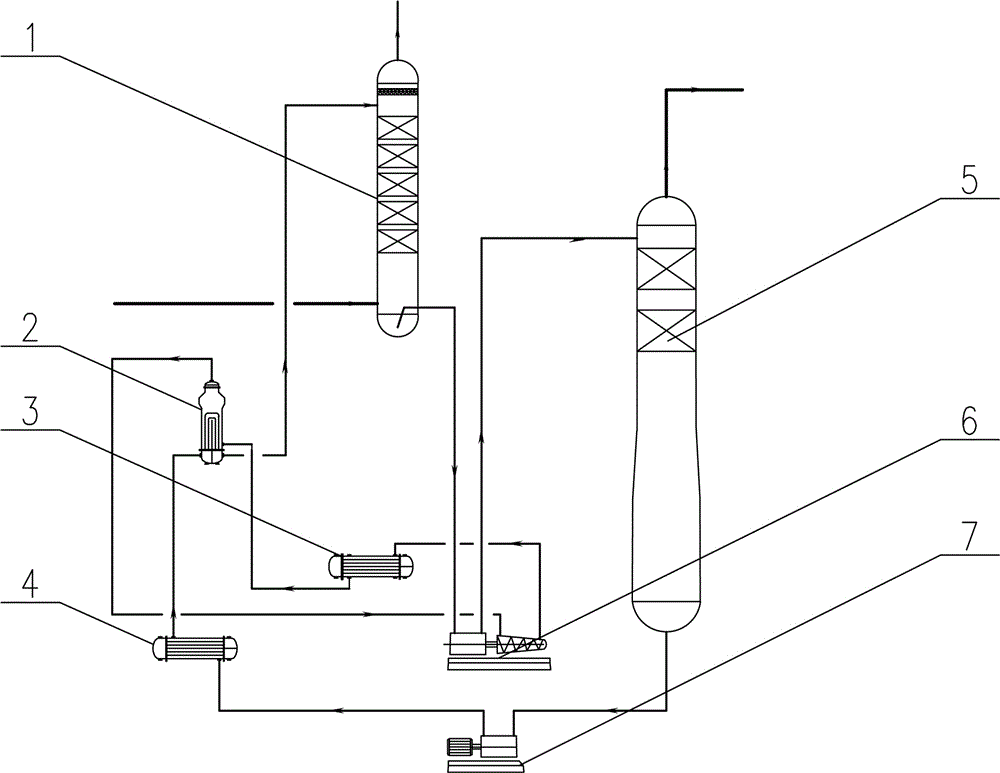

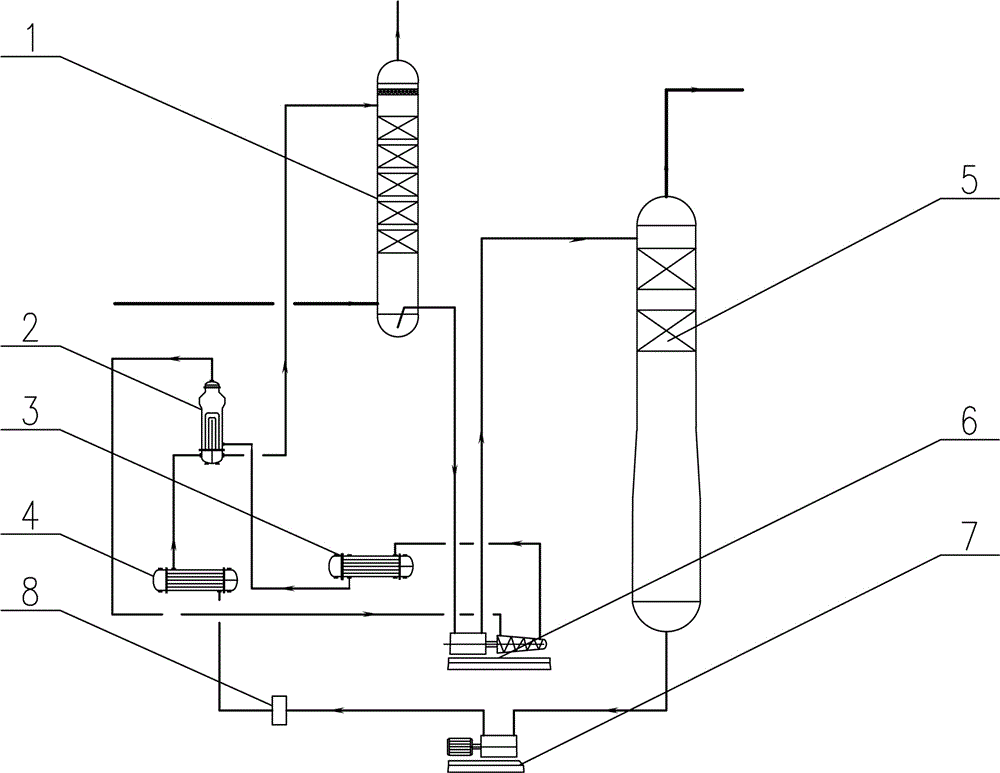

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] A carbon propylene decarburization method carbon propylene liquid pressure energy recovery method. The method includes depressurization-cooling;

[0025] The decompression: the high-temperature and high-pressure carbon-acrylic liquid in the decarburization tower drives the compressor by acting on the turbine to perform preliminary decompression, and then performs secondary decompression through the flash tower;

[0026] Said cooling: the depressurized carbon-acrylic liquid in the flash tower passes through the water cooler under the action of the decarburization pump, and enters the refrigerant circulating cooling system such as ammonia and freon, and the compressor circulates the ammonia, freon and other refrigerants in the cooling system. Refrigerants such as Freon are compressed and condensed, and the temperature is lowered after the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com