Crude oil shipping oil and gas recycling method

A recovery method and technology for oil and gas, applied in separation methods, chemical instruments and methods, liquid hydrocarbon mixture recovery, etc., can solve the problems of difficulty in processing sulfur-containing waste lye, increase operating costs and processing difficulty, and avoid waste lye. The effect of dealing with problems, low actual operating costs, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

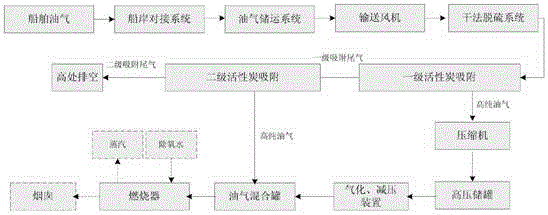

[0030] Such as figure 1 Shown, crude oil shipment oil gas recovery method of the present invention, comprises the steps:

[0031] A. Use the gas transmission arm or gas transmission hose of the ship-to-shore docking system to connect with the oil and gas special interface of the tanker, and draw out the gas containing oil and gas in the cabin during the loading operation of the tanker, and the drawn oil and gas are sent to the oil and gas recovery device. , will pass through the online monitoring system. The front pipeline of the online monitoring system is equipped with a breathing valve and a safety valve. The set pressure values of the breathing valve are -3.5Kpa (G) and 1.4Kpa (G). Shut-off valve;

[0032] The online monitoring system can monitor the oxygen content, hydrocarbon concentration, sulfur concentration, oil and gas pressure, temperature and flow parameters of oil and gas online, and realize the functions of self-check, automatic alarm and automatic protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com