A kind of lithium battery and preparation method thereof

A lithium battery and cell technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problem of positive plate/negative plate rolling, difficult operation of plate core winding, and limit the development of thinner batteries and other issues to achieve the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

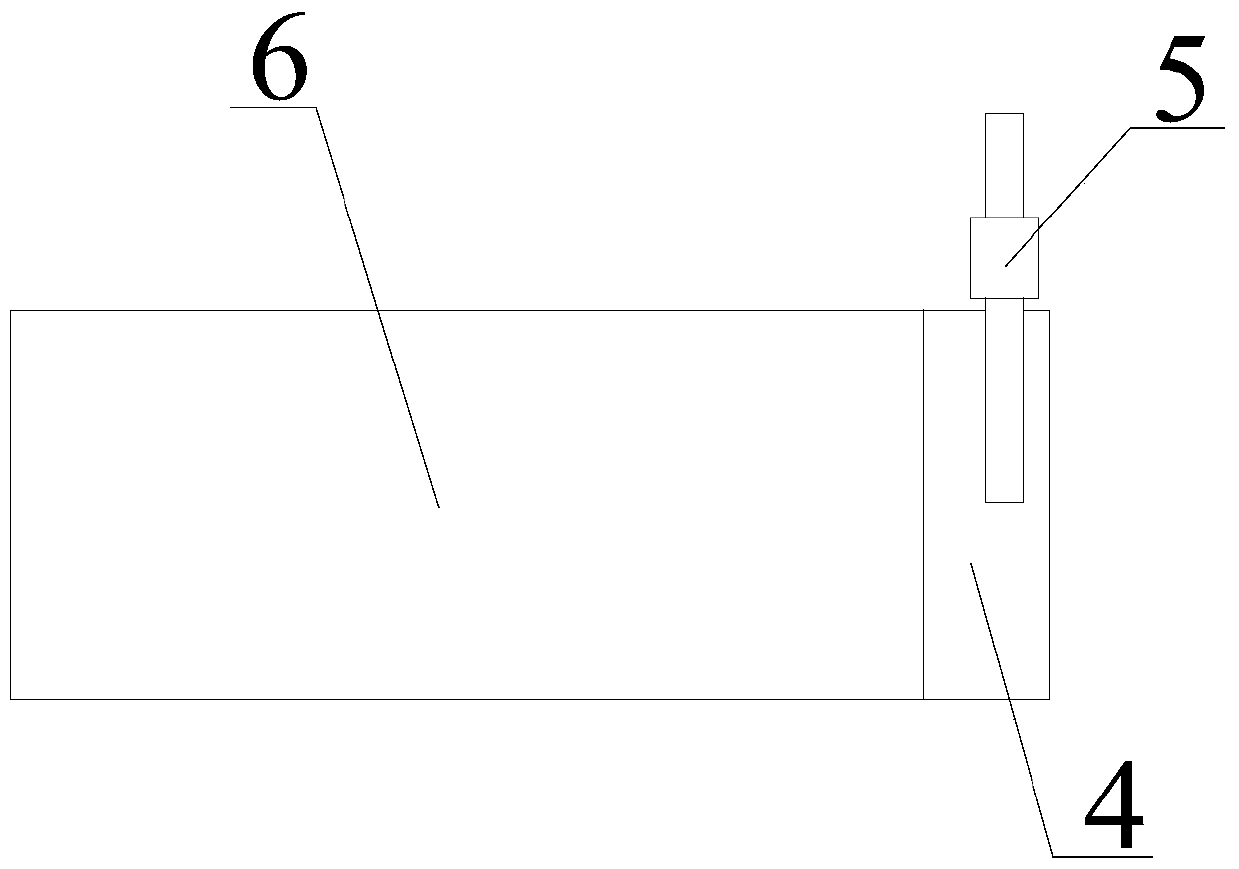

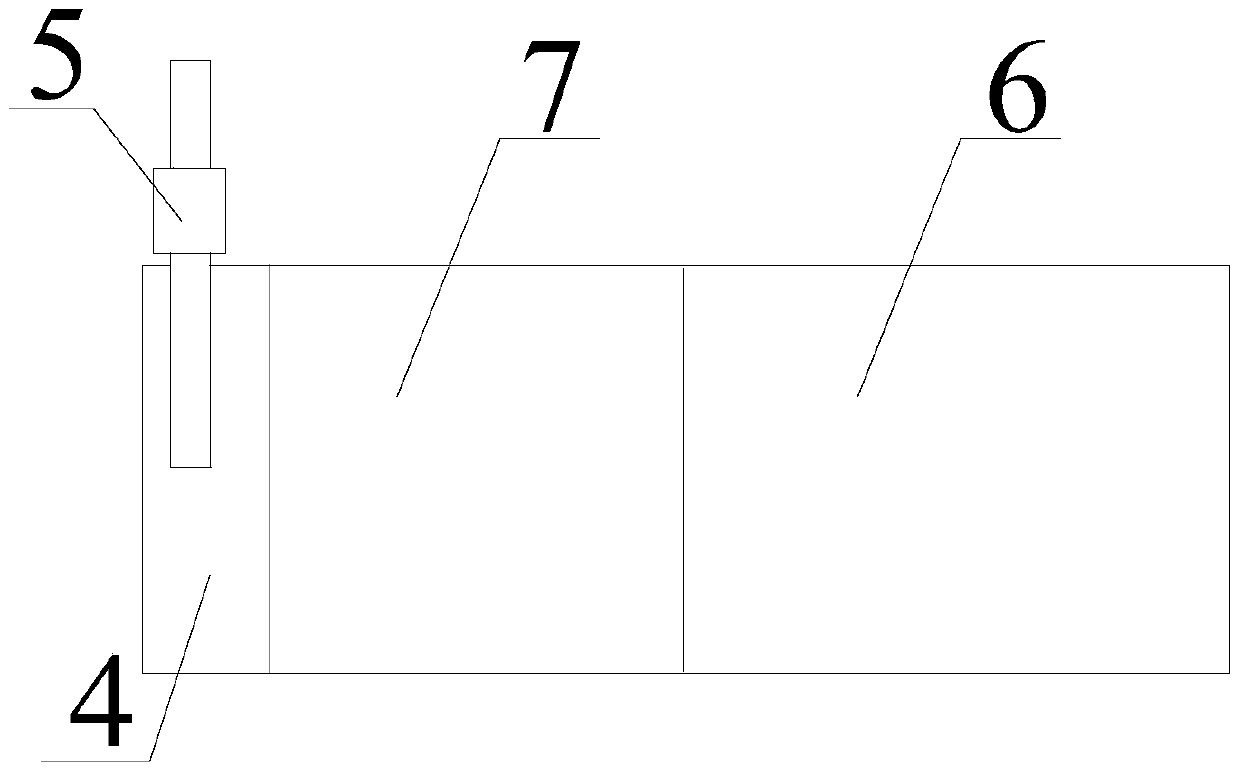

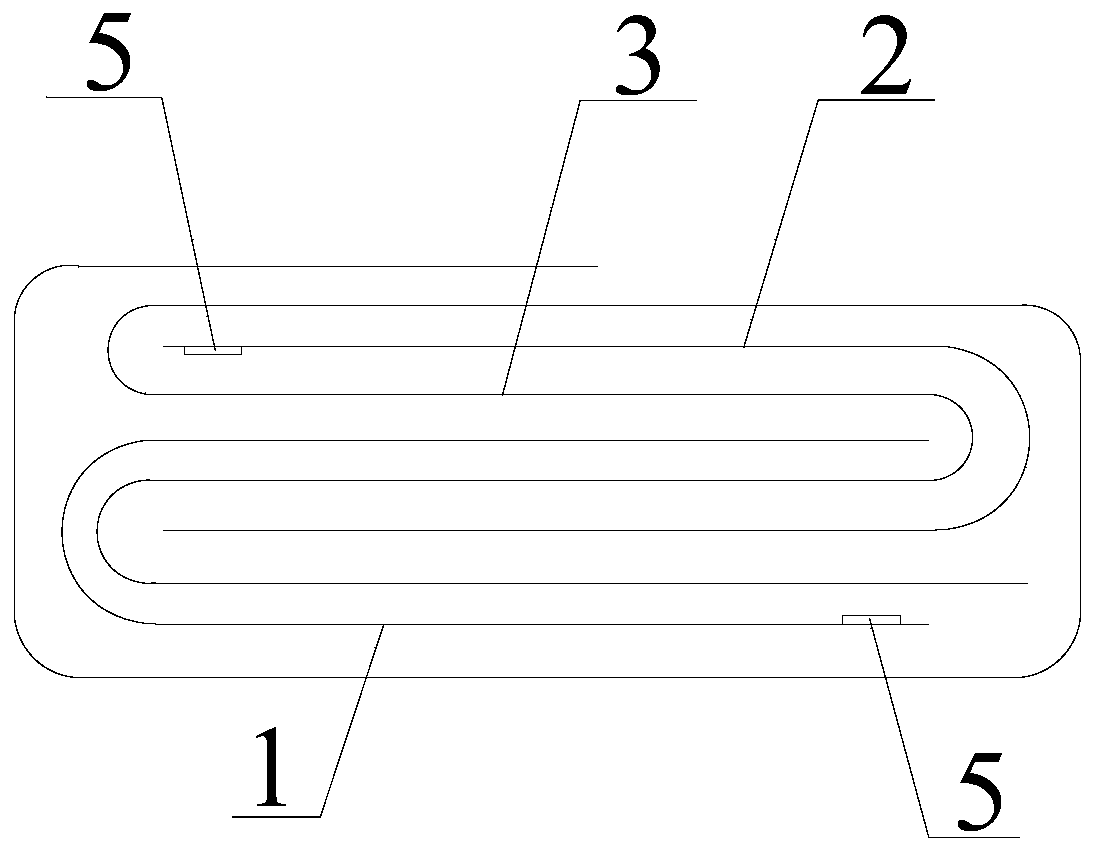

[0029] like Figure 1-3 As shown, a lithium battery includes a flat winding type battery core, the winding type battery core includes two pole plates, respectively a positive plate 1 and a negative plate 2, and a diaphragm 3 is arranged between the two pole plates ;

[0030] The ends of the pole plates are all provided with spot welding empty foil areas 4 for connecting the pole lugs 5. The front side of the pole plate is the powder area 6, and the back includes the powder area 6 and the non-powder area 7. The non-powder area 7 on the back of the pole plate is located at the Spot welding between the empty foil area 4 and the powder area 6, and the area of the non-powder area 7 is not larger than the area of the powder area 6;

[0031] The ends of the two pole plates face oppositely, and the two pole tabs 5 are arranged on both ends of the width direction of the wound battery core, and are respectively located at the top and bottom of the wound battery core.

[0032] In t...

Embodiment 2

[0035] like Figure 1-3 As shown, a lithium battery includes a flat winding type battery core, the winding type battery core includes two pole plates, respectively a positive plate 1 and a negative plate 2, and a diaphragm 3 is arranged between the two pole plates ;

[0036] The ends of the pole plates are all provided with spot welding empty foil areas 4 for connecting the pole lugs 5. The front side of the pole plate is the powder area 6, and the back includes the powder area 6 and the non-powder area 7. The non-powder area 7 on the back of the pole plate is located at the Spot welding between the empty foil area 4 and the powder area 6, and the area of the non-powder area 7 is not larger than the area of the powder area 6;

[0037] The ends of the two pole plates face oppositely, and the two pole tabs 5 are arranged on both ends of the width direction of the wound battery core, and are respectively located at the top and bottom of the wound battery core.

[0038] The ...

Embodiment 3

[0045] like Figure 1-4 As shown, a preparation method of a lithium battery includes the following steps:

[0046]Prepare the positive plate 1 and the negative plate 2; reserve the spot welding empty foil area 4 at the end of the pole plate, the front side of the pole plate is the powder area 6, the back part is the powder area 6, and the non-powder area 7 and the non-powder area 7 are reserved. It is located between the powder area 6 and the spot welding empty foil area 4, and the width of the non-powder area 7 is not greater than the width of the powder area 6. The powder area 6 of the positive plate 1 is coated with positive powder, and the spot welding empty foil area 4 is connected to the positive electrode ear, the powder area 6 of the positive plate 1 is coated with negative electrode powder, and the spot welding empty foil area 4 is connected to the negative electrode ear;

[0047] Winding forming: winding the middle of the diaphragm 3 into an S shape including two op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com