Excess material early warning type submerged arc welding machine and using method thereof

A submerged arc welding machine and residual material technology, which is applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of not having automatic flux addition and burning eyes, and achieve the effect of avoiding arc light burning eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

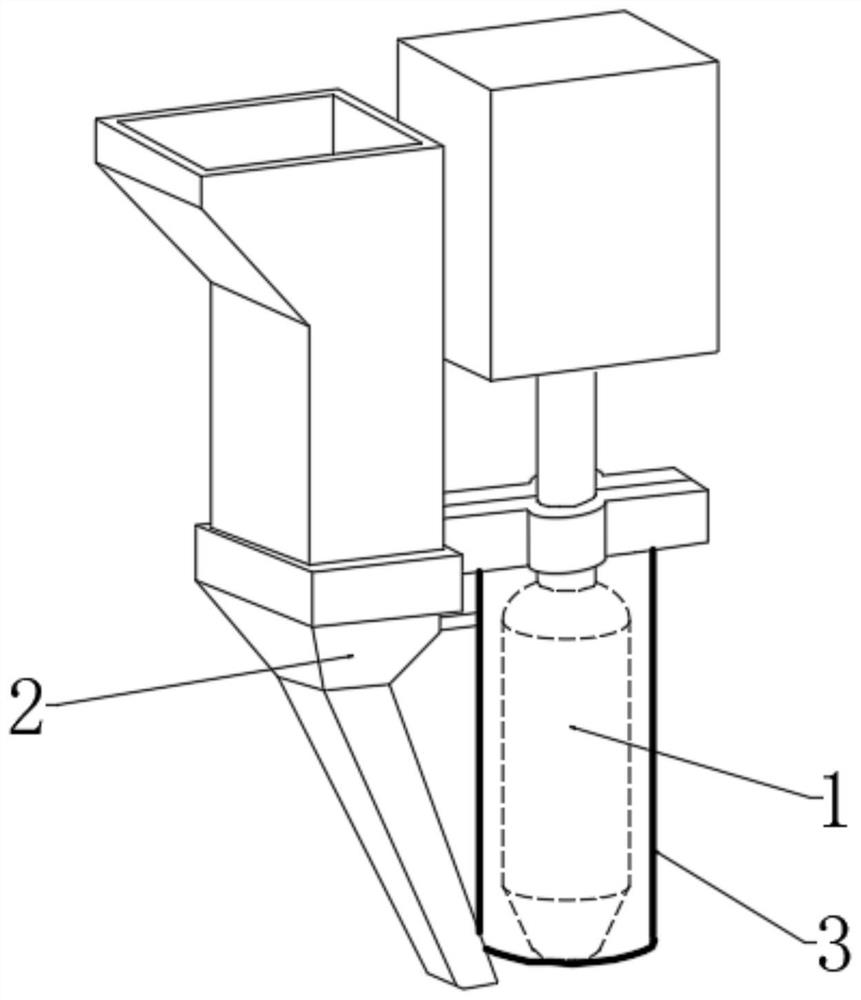

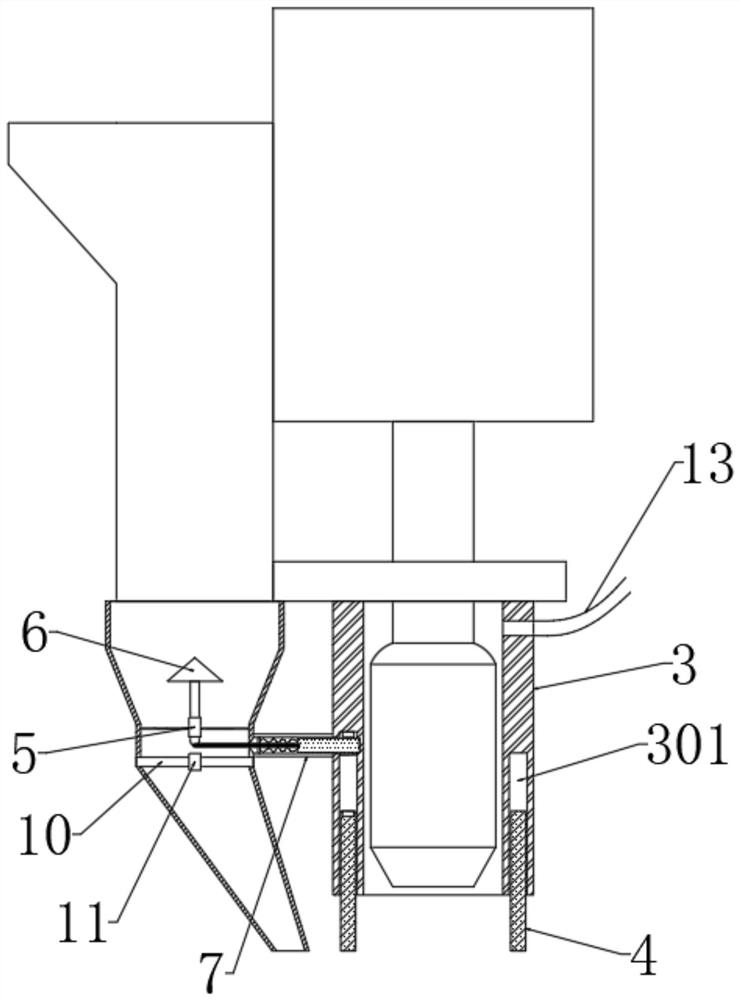

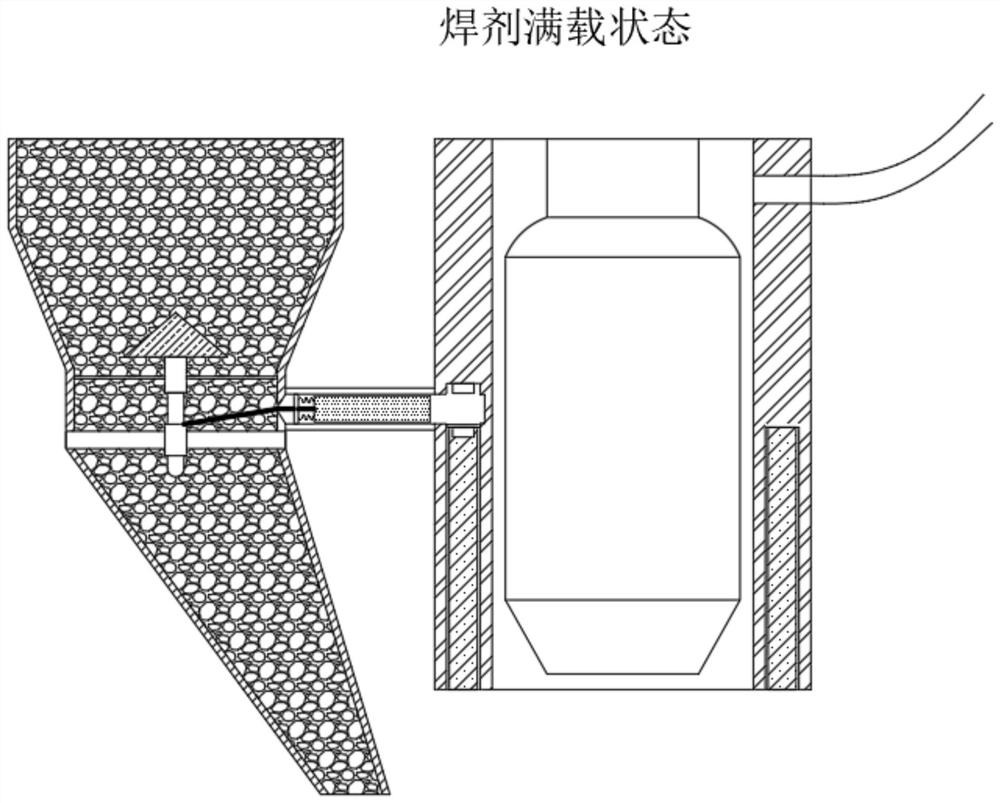

[0046] see Figure 1-8 , a residual material warning type submerged arc welding machine, including a welding torch 1 and a flux box 2, please refer to figure 1 , 2 , 8, the outer cover of the welding torch 1 is covered with a protective cover 3, the upper side wall of the protective cover 3 is connected with an exhaust pipe 13, and the outer end of the exhaust pipe 13 is connected with an exhaust fan, although it does not produce visible smoke like manual arc welding during welding , but will produce a certain amount of harmful gas and steam, so the harmful gas is pumped out by the exhaust fan to be filtered and then discharged, which not only protects the environment, but also protects the health of the staff. The inner wall of the lower end of the protective cover 3 is provided with a storage chamber 301, and a light shield 4 is slidably connected in the storage cavity 301, and the light shield 4 is provided with a material opening 401 along the side wall of the welding tor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com