Special long-acting cutting fluid for aluminum alloy

A technology of aluminum alloy and cutting fluid, applied in the field of special long-acting cutting fluid for aluminum alloy, can solve the problems of short cutting time, poor economic benefit, easy sticky chips, etc., and achieve low maintenance cost, long cleaning cycle and stable microemulsion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

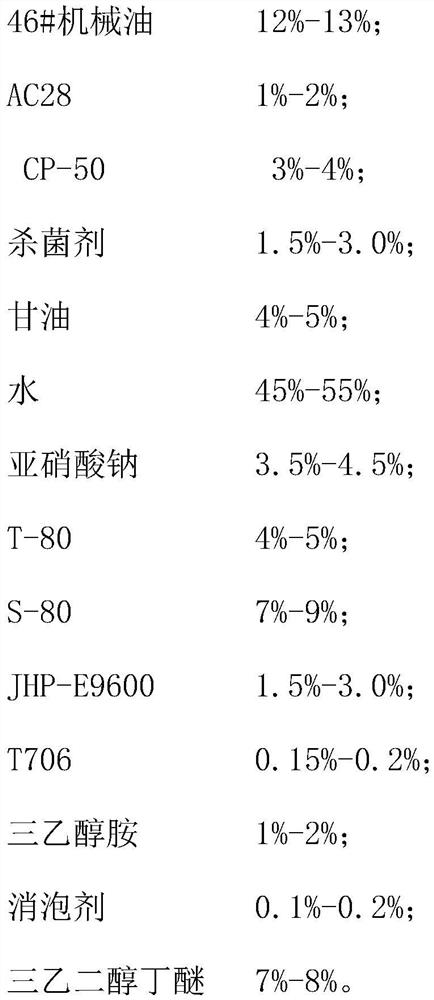

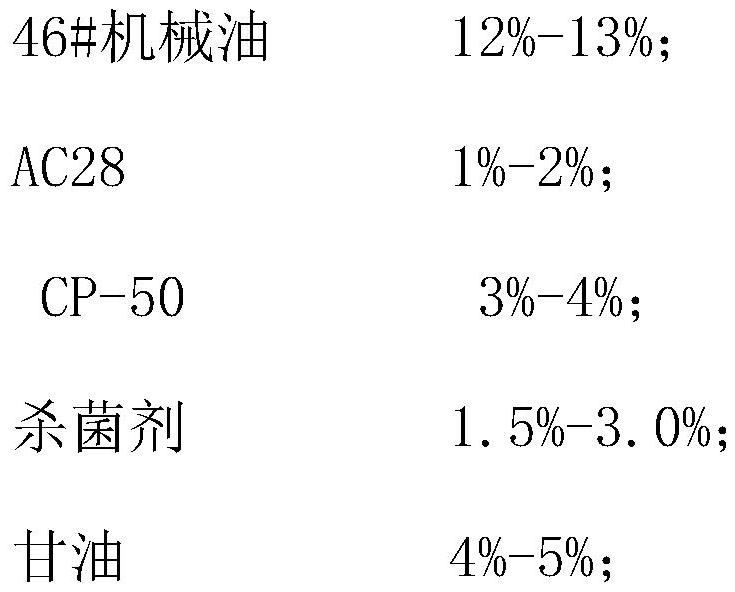

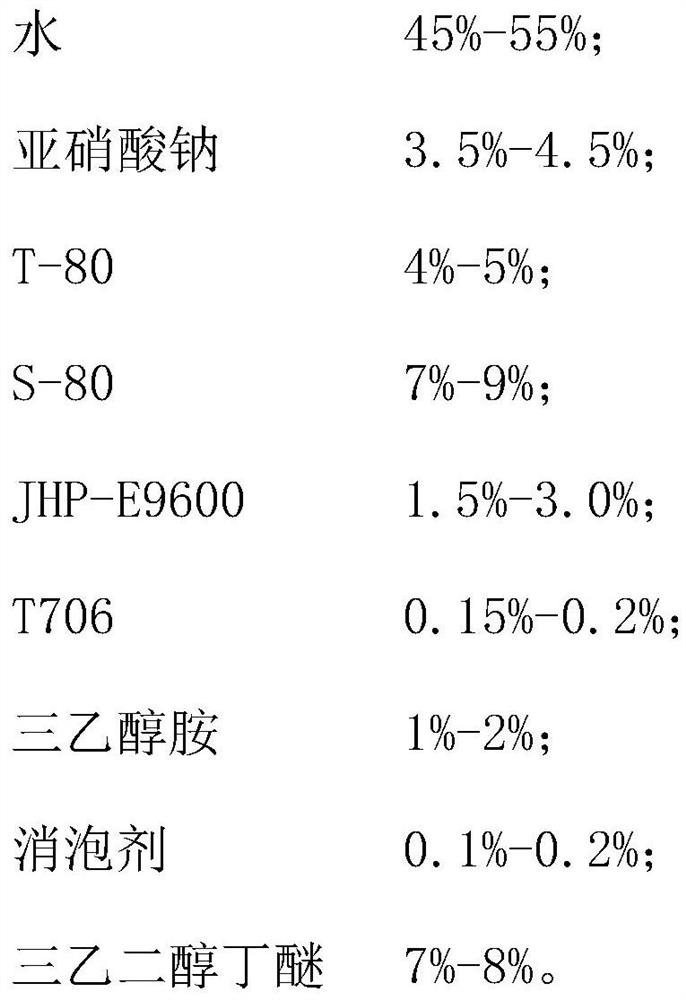

[0023] A special long-acting cutting fluid for aluminum alloys, comprising the following components by mass percentage, 46# machine oil, 12.28%; AC28, 1.23%; CP-50, 3.07%; bactericide (BK), 1.84%; glycerin , 4.00%; Water, 50.37%; Sodium Nitrite, 3.84%; T-80, 4.48%; S-80, 8.00%; agent, 0.12%; triethylene glycol butyl ether, 7.52%.

Embodiment 2

[0025] A special long-lasting cutting fluid for aluminum alloys, comprising the following components by mass percentage, 46# mechanical oil, 12.50%; AC28, 1.5%; CP-50, 3.5%; bactericide, 3%; glycerin, 4% ; Water, 50.1%; Sodium Nitrite, 3.5%; T-80, 4%; S-80, 7%; JHP-E9600, 1.5%; %; Triethylene glycol butyl ether, 8%.

Embodiment 3

[0027] A special long-lasting cutting fluid for aluminum alloys, comprising the following components by mass percentage, 46# mechanical oil, 13%; AC28, 1%; CP-50, 3%; bactericide, 1.5%; glycerin, 4% ; Water, 47.25%; Sodium Nitrite, 4.5%; T-80, 5%; S-80, 9%; JHP-E9600, 2.5%; %; Triethylene glycol butyl ether, 7%.

[0028] Described 46# machine oil is non-standard machine oil, and this machine oil has good lubricity, moderate viscosity.

[0029] The AC28 is tall oil amide concentrated solution, which is a kind of co-emulsifier, which plays a role in stabilizing the system in this prescription, preventing the stock solution from abnormality and oil separation.

[0030] Described CP-50 is a kind of tribasic acid antirust agent, is prepared by tribasic acid: triethanolamine: water, ratio is 1:2.8:1, and tribasic acid is the tribasic acid of content 50%, and triethanolamine is 85% triethanolamine mixed amine, the water is hard water, 0--500mg / L neutral water, first add triethanola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com