Plush laser embossing machine

An embossing machine and embossing technology, which is applied to textiles and papermaking, fabric surface trimming, and thorn patterns, etc., can solve the problems of expensive equipment, long manufacturing cycle of pattern rollers, and low production efficiency, and achieve the effect of convenient operation and various patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

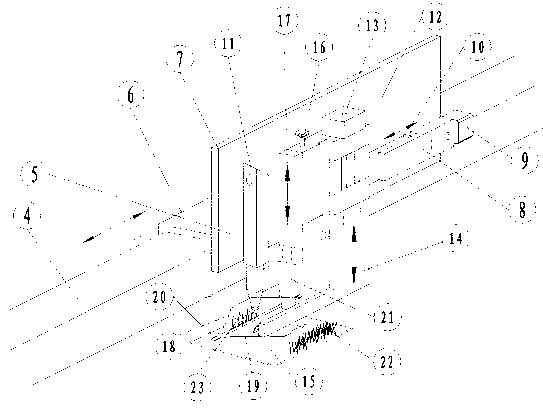

[0015] The plush laser embossing machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

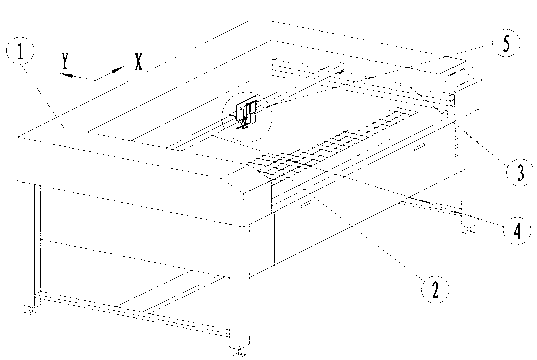

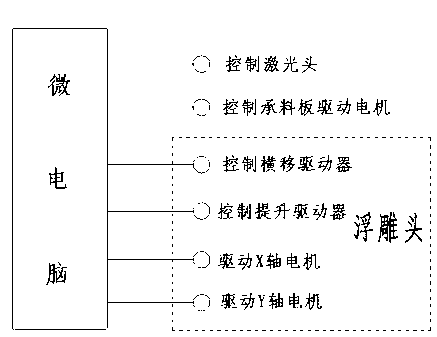

[0016] like figure 1 As shown, the plush laser embossing machine of the present invention includes a workbench 1, a microcomputer (not shown) and an embossing head 5. The workbench 1 is mainly made of metal profiles and plates. The materials, working principles and usage methods of its components are the same as those of most machine tools, including the frame, the material receiving plate 2, the X-axis guide rail 4 and the Y-axis guide rail 3. The material bearing plate 2 is arranged on the frame, and adopts a metal mesh plate or a wire mesh conveyor belt. The X-axis guide rail 4 and the Y-axis guide rail 3 can be made of screw mandrel, synchronous belt+synchronous wheel, gear+rack mechanism and equipped with a drive motor. The Y-axis guide rail 3 is arranged above the material receiving plate 2 , and the X-axis guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com