Aeolian sand and loess hopper vibration type discharging device

A vibrating, aeolian sand technology, used in transportation and packaging, packaging, chemical instruments and methods, etc., can solve the problems of manual cleaning, insufficient supply of materials, affecting ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

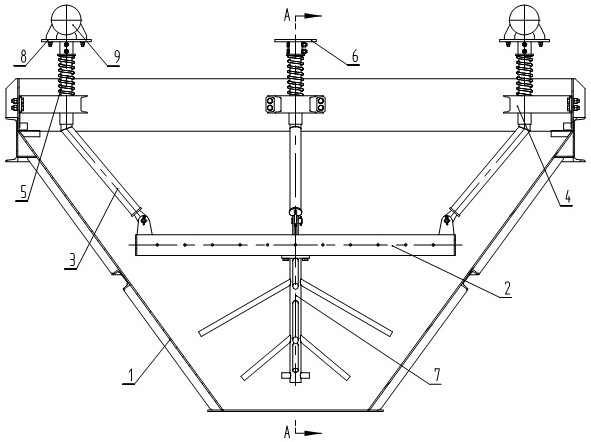

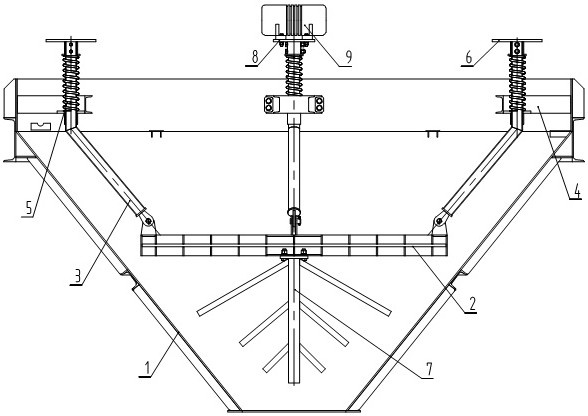

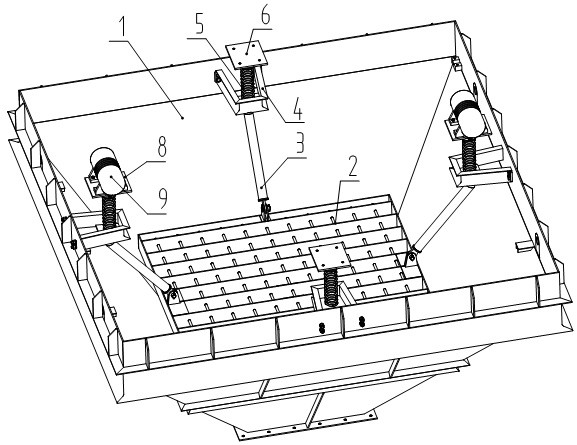

[0032] Embodiment 1: The vibratory blanking device includes: a hopper 1, a vibrating grate 2, a vibrating pull rod 3, a spring support 4, a spring 5, a mounting plate 6, a rapping device 7, a vibrating motor seat 8 and a vibrating motor 9;

[0033] The upper end of the vibrating rod 3 is connected with a mounting plate 6 or a vibrating motor base 8, and the vibrating motor base 8 is connected with a vibrating motor 9, and the mounting plate 6 is used to fix the vibrating feeding device; the lower end of the vibrating rod 3 is connected with a vibrating grate The net 2 is connected with the rapping device 7 at the middle position of the bottom surface of the vibrating grate net 2; the spring bracket 4 is connected with the inner wall of the upper end of the hopper 1; The lower end of the seat sits on the spring support 4, and the vibration pull rod 3 can slide in the spring 5.

[0034] The rapping device 7 includes: inclined side bar 7-1; bottom cross bar 7-2; main bar 7-3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com