Molded composite board with improved firmness and preparation method thereof

A composite board and solid technology, applied in the field of building wall materials, can solve the problems of poor strength of the composite board, easy peeling and deformation of the insulation layer and the lining layer, and achieve low cost, product application value and market promotion The effect of high price and balanced coefficient of thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following, specific embodiments are described in detail with the attached drawings, so that it is easier to understand the purpose, technical content, characteristics and effects of the present invention.

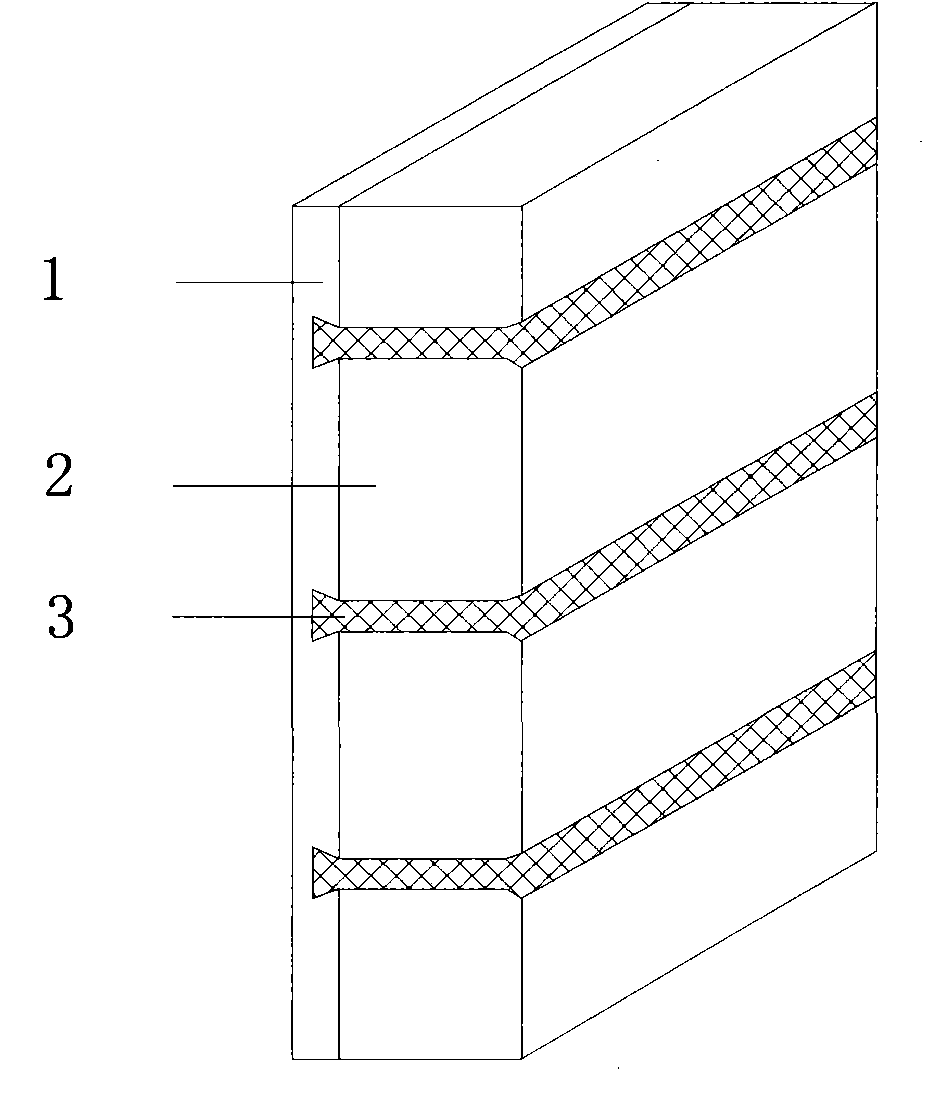

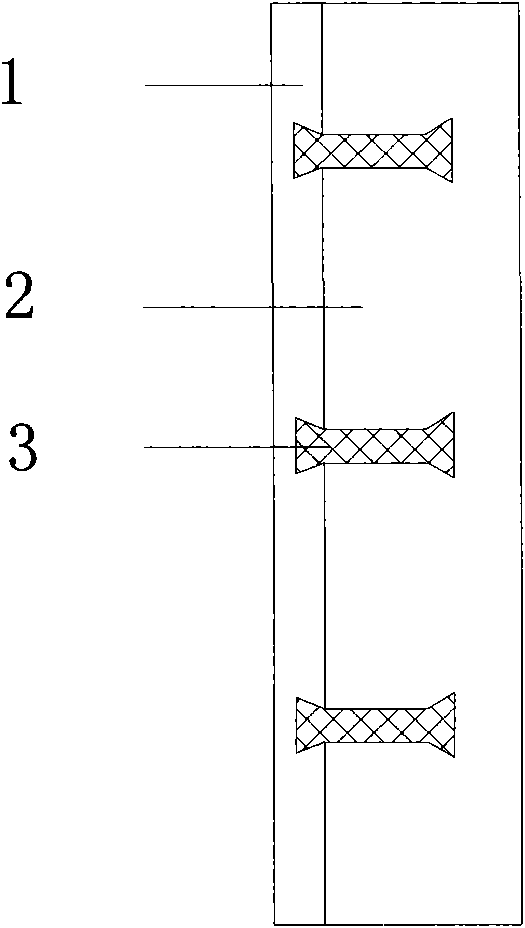

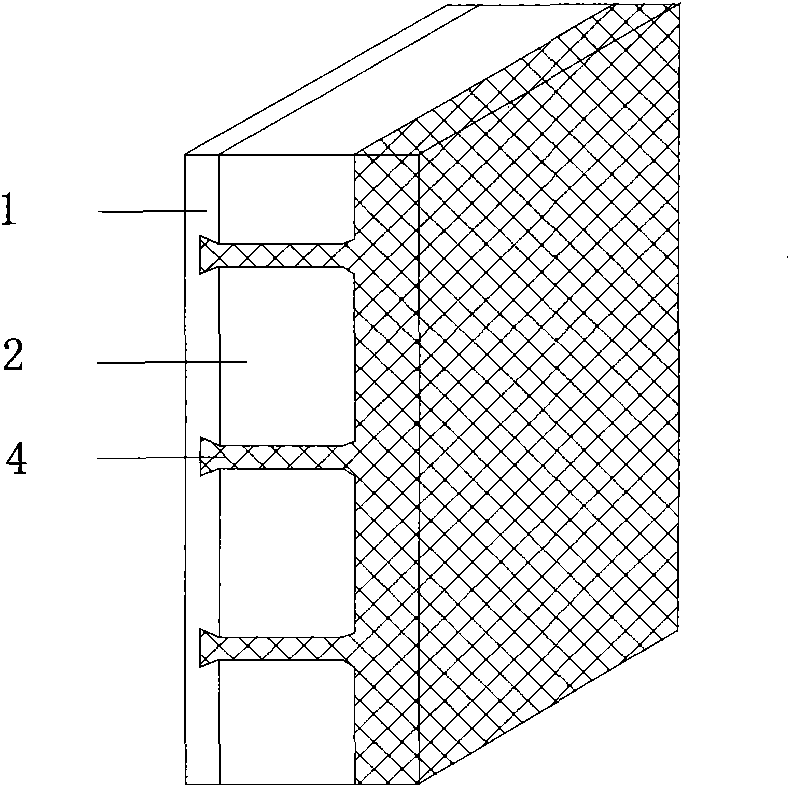

[0038] figure 1 It is a structural schematic diagram of the composite board according to the present invention, such as figure 1 As shown, a molded composite board with improved firmness includes a lining layer 1 and an insulating layer 2. On the opposite side of the two, a plurality of grooves are correspondingly opened, and the grooves in the insulating layer 2 have been formed. Through the front and back, the insulation layer is divided into several pieces, and the foamed polyurethane 3 is arranged in the groove, which forms an anchor shape, so that the lining layer and the insulation layer are closely combined to form a permanent bond.

[0039] The cross-section of the groove in the composite plate can be other arbitrary shapes besides the anchor shape, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com