A kind of bevel cutting equipment for rectangular square tube of electric tower

A technology for rectangular square tubes and power towers, which is applied in shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems that rectangular square tubes cannot be misconnected, the work flow is cumbersome, and it is not easy to cut rectangular steel tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways of pretty and covered.

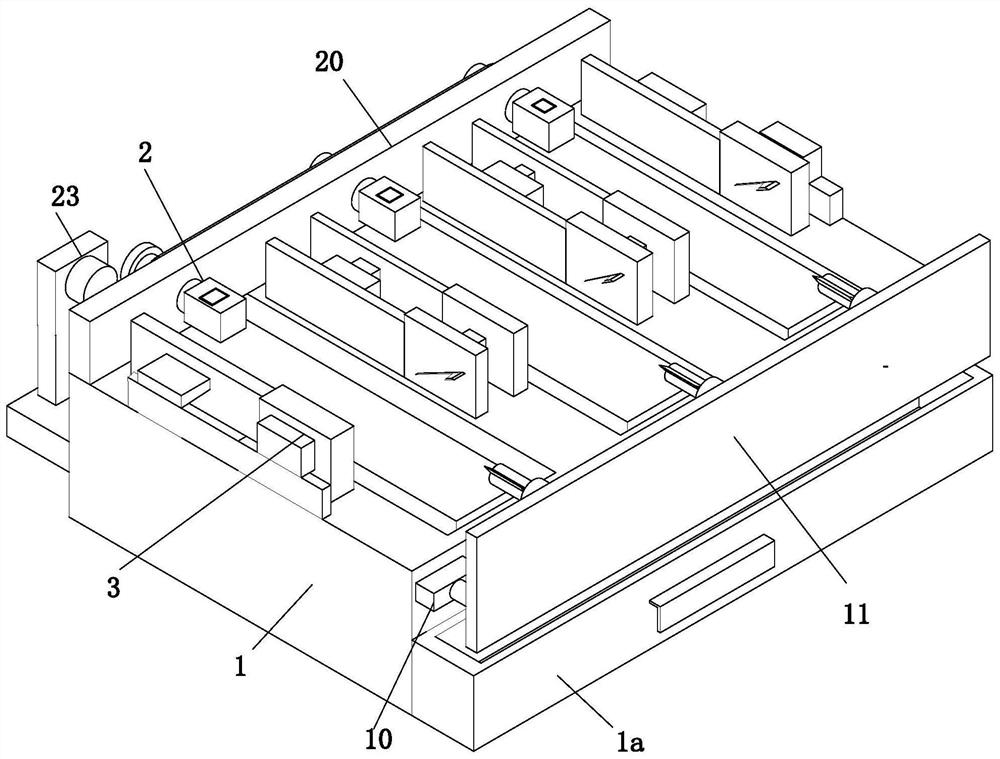

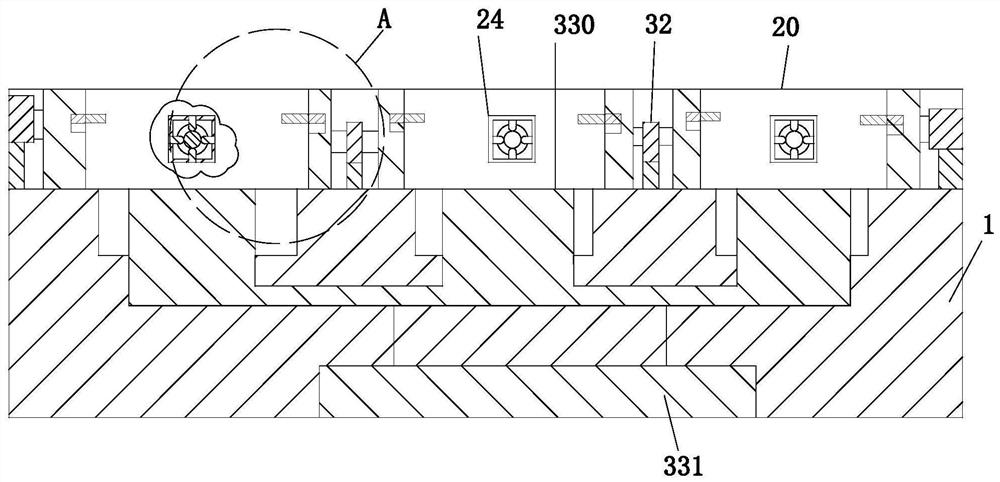

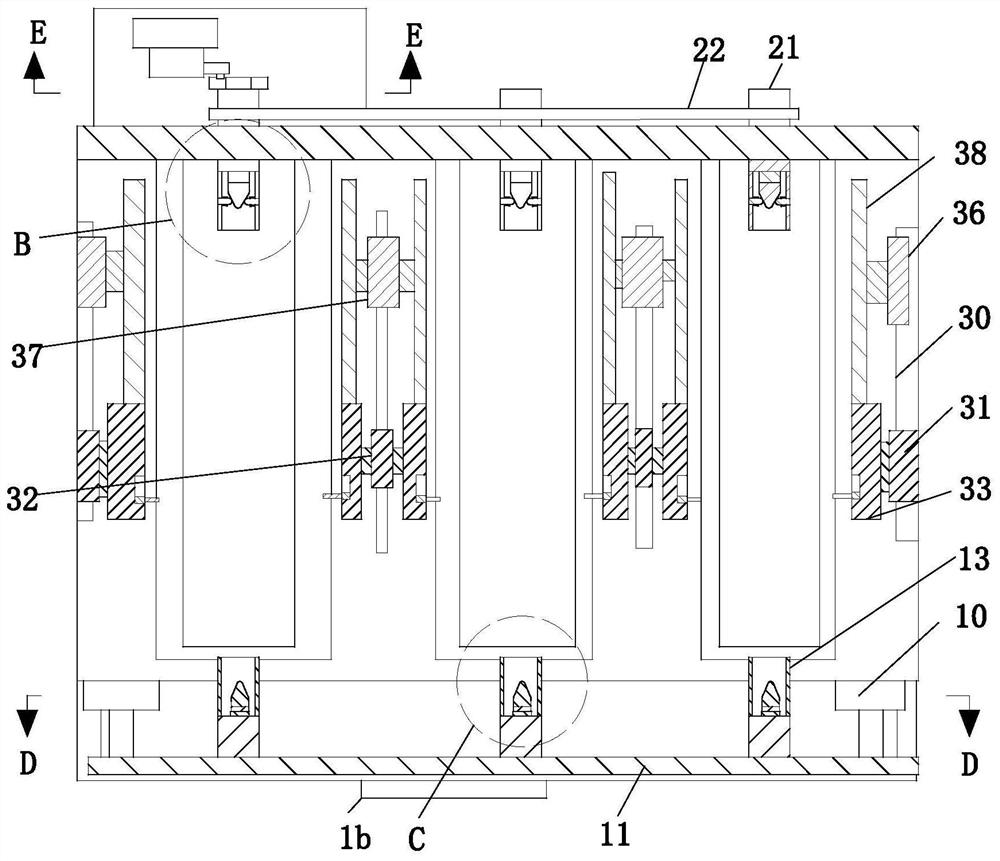

[0029] like Figure 1 to 9 As shown, a power tower rectangular square tube is obliquely cutting apparatus, including a table 1, a tightening rotating mechanism 2, and a fixed cutting mechanism 3, and the table 1 is mounted on the work ground, the rear end mount of the workbench 1 There is a card tensioning mechanism 2, and the upper end surface of the table 1 is installed with a fixed cutting mechanism 3.

[0030]The front end surface of the table 1 is mounted with a first electric cylinder 10, and a connecting plate 11 is mounted on the electric cylinder 10, and the front end surface of the connecting plate 11 is mounted by the bearing, and the rotating column 12 is left from left to right. The equal distance arrangement, the front end surface of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com