Polystyrene composite decorative plate

A technology of polystyrene board and polystyrene, applied in covering/lining, building, building structure, etc., can solve the problems of destroying architectural decoration style, affecting urban architectural planning, high project cost, etc., and achieves long service life and unique Practicality and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

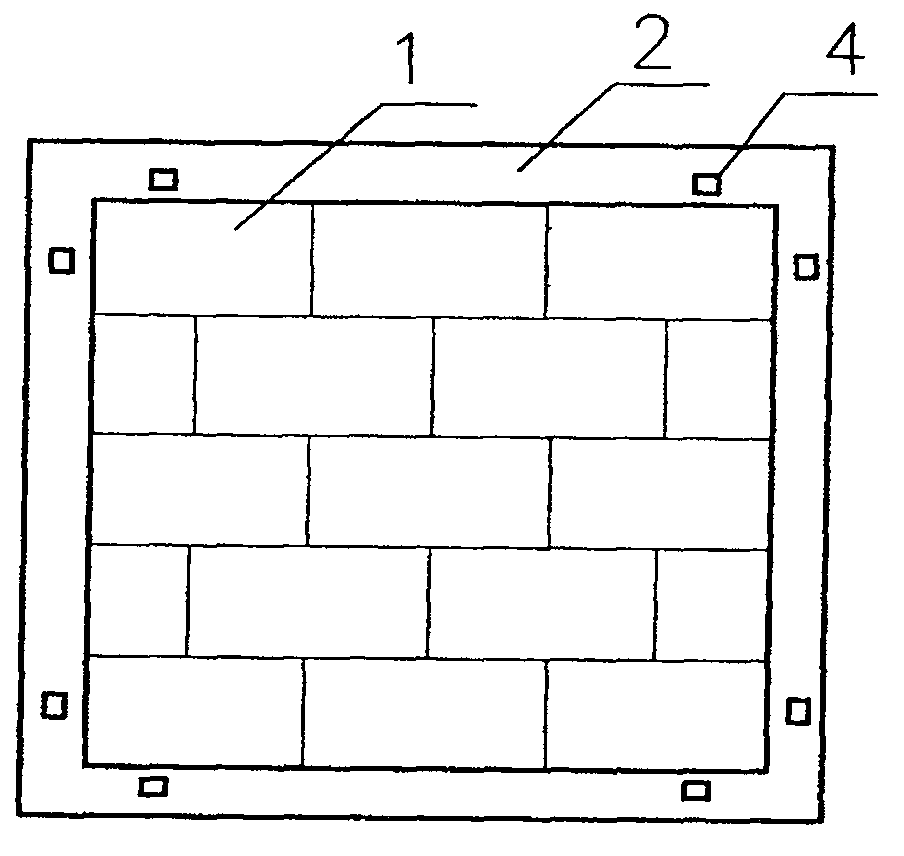

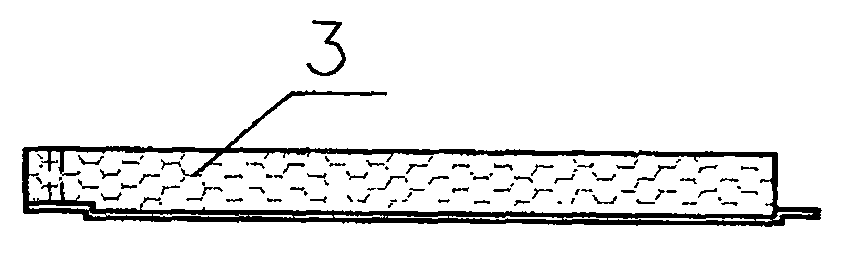

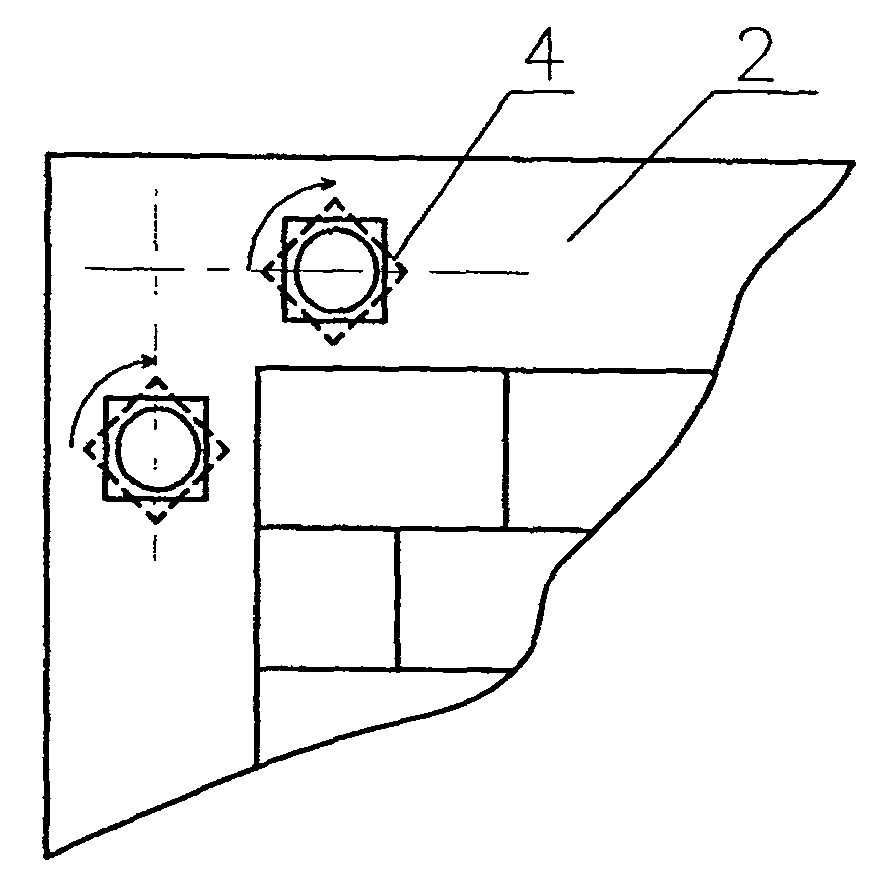

[0017] Polystyrene composite decorative board is made by bonding decorative board and polystyrene board. The production process is as follows:

[0018] 1. Plate forming: the metal plate is 0.4-1.5mm thick, and the design mold is installed on the punching machine for stamping or stretching. The required forming plate specifications are different, and the length and width of the plate are generally controlled within the range of 600-800mm. Or use the casting process to make a plastic decorative board with a thickness of 1.5 mm to 3 mm.

[0019] 2. Clean the formed plate, use a special cleaning agent for metal, and then dry it, which can be used: ①Natural drying; ②Drying in a drying room, the room temperature is 70-80°C.

[0020] 3. After drying, spray anti-corrosion primer 9, choose epoxy primer for overall anti-corrosion treatment, and then dry, the method is the same as above.

[0021] 4. Spray the polyester protective paint on the back of the plate after anti-corrosion treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com