Method for preparing paper-cut artwork

A production method and technology of handicrafts, applied in the fields of crafts for producing decorative surface effects, decorative art, special patterns, etc., can solve the problems of low precision and achieve the effect of high production efficiency, various patterns, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

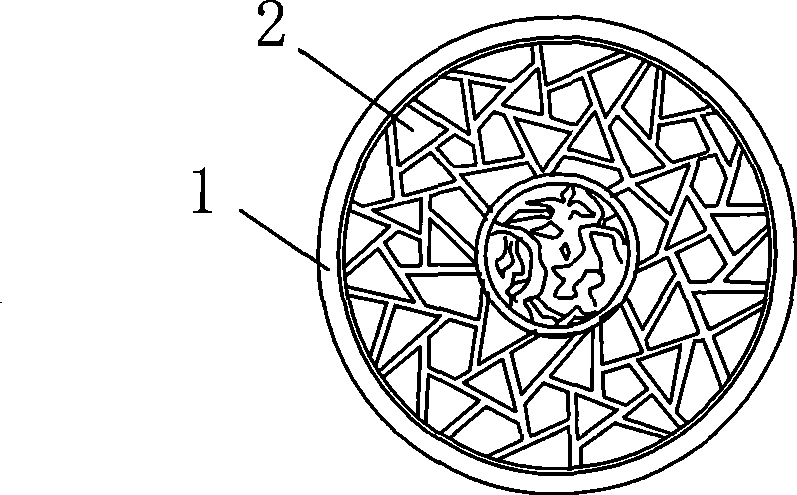

[0021] The present invention as figure 1 As shown, the tools and profiles that need to be used in this method are:

[0022] 1. Computer (used to draw exquisite graphics);

[0023] 2. Engraving tools (scalpel, oblique knife, file);

[0024] 3. ABS sheet;

[0025] A kind of manufacture method of window flower handicraft, its manufacture step is:

[0026] a. First, select a photo, process the photo with a computer, and draw it into a line drawing; print out the drawn line drawing with a ratio of 1:1;

[0027] b. According to the size of the figure, select the ABS plate; the purpose of using the ABS plate is: environmental protection, fine texture, uniform density, no matter how delicate the carving is, it will not break, and it is suitable for fine carving.

[0028] c. Attach the printed drawings to the ABS board, cut off the surrounding large pieces with a scalpel, and then use a scalpel and an oblique knife to cut off the hollowed out position of the graphics;

[0029] d. ...

Embodiment 2

[0035] The present invention as figure 1 As shown, the tools and profiles that need to be used in this method are:

[0036] 1. Computer (used to draw exquisite graphics);

[0037] 2. Engraving tool (file);

[0038] 3. ABS sheet;

[0039] 4. Computer-operated engraving machinery;

[0040] A kind of manufacture method of window flower handicraft, its manufacture step is:

[0041] a. First, select a photo, process the photo with a computer, and draw it into a line drawing; print out the drawn line drawing with a ratio of 1:1;

[0042] b. According to the size of the figure, select the ABS plate; the purpose of using the ABS plate is: environmental protection, fine texture, uniform density, no matter how delicate the carving is, it will not break, and it is suitable for fine carving.

[0043] c. Attach the printed drawings to the ABS board, and use the computer to operate the engraving machine to cut off the hollowed-out position of the graphics;

[0044] d. Use sandpaper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com