Making method of opening type finger ring with concave-convex patterns on surface as well as finger ring

A production method and technology of concave-convex patterns, applied to rings, techniques for producing decorative surface effects, decorative arts, etc., can solve the problems of complex processing, increased three-dimensional effect, poor three-dimensional effect, etc., and achieve simple processing and three-dimensional effect , a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention are described with reference to the above drawings.

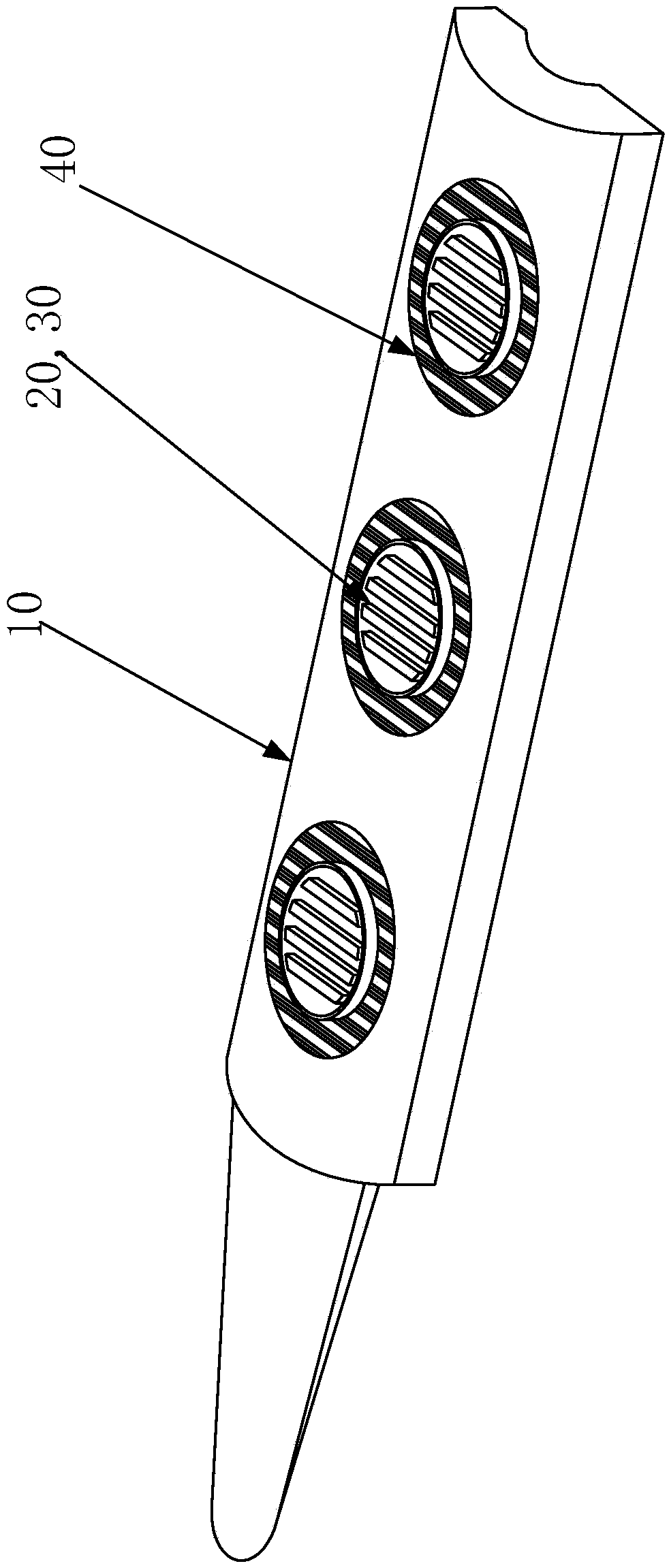

[0011] The method for making the concave-convex pattern on the surface of the open ring of the present invention comprises the following steps: A. Engraving the concave-convex pattern on the stamping die; B. Putting the ring material into the stamping die to stamp it into a strip-shaped ring blank 10, And form a raised pattern 20 and a concave pattern 30 on the surface of the ring; C. After post-processing the ring blank, an open ring is formed.

[0012] In the present invention, patterns are engraved in stamping dies. During the stamping process, ring blanks are extruded to form concavo-convex patterns on the surface, increasing the three-dimensionality of the pattern on the surface of the ring.

[0013] In order to further enrich the diversity and perception of the surface of the ring, the post-processing described in step C includes the following sub-steps: C1. rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com