Preparation method of double-faced jacquard knitted vamp

A double-sided jacquard and jacquard needle technology, applied in knitting, weft knitting, footwear, etc., can solve the problems of single color and flowers on one side, and achieve the effect of comfortable wearing, beautiful appearance and reduced equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

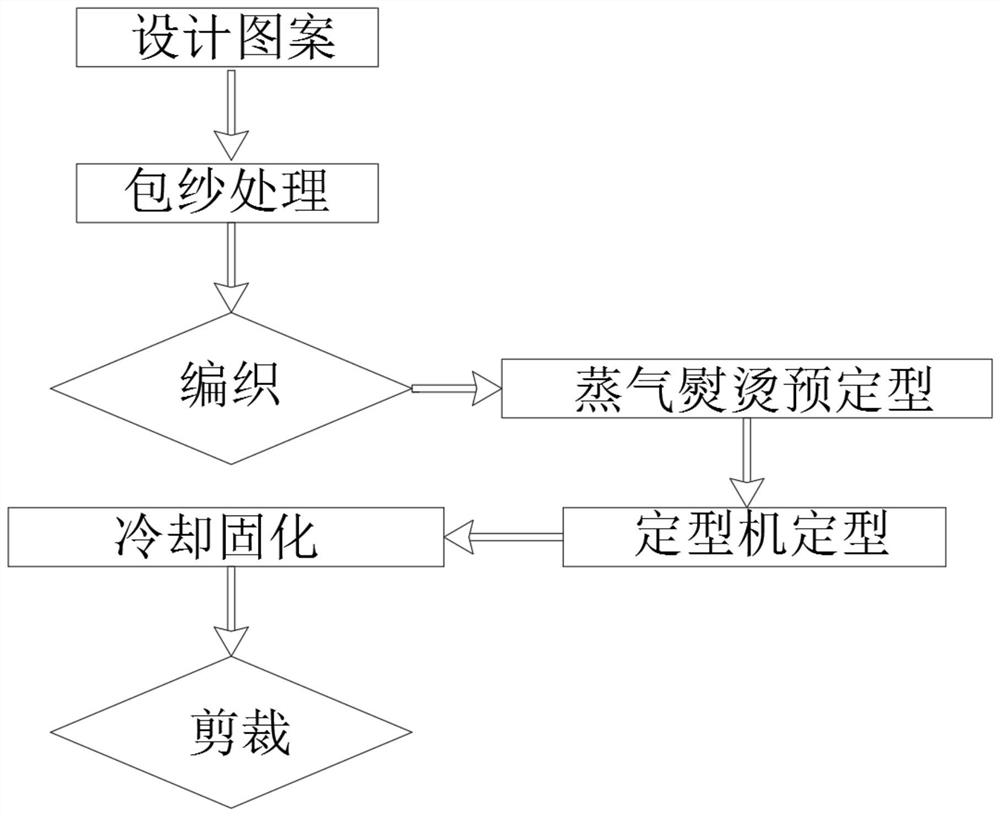

[0033] refer to figure 1 , a method for preparing a double-sided jacquard knitted shoe upper, comprising the following steps:

[0034] S1: Design patterns, use double-sided jacquard knitting upper computer plate-making, design the surface pattern of jacquard knitted fabrics, use computer-making weft-knitting jacquard not only to make the upper material, pattern, color and style changeable and beautiful, but also low-cost The advantages of carbon environmental protection, avoiding the traditional sports uppers made of leather or rubber, resulting in greater product pollution;

[0035] S2: Yarn wrapping treatment, using the conventional yarn wrapping process to wrap the spandex with hot-melt yarn to obtain a hot-melt yarn rack;

[0036] S3: knitting, sending the hot-melt wire frame obtained in S2 together with the conventional knitting yarn into a computerized flat knitting machine to knit a semi-finished double-sided jacquard knitted shoe upper with a preset pattern;

[0037]...

Embodiment 2

[0044] refer to figure 1 , a method for preparing a double-sided jacquard knitted shoe upper, comprising the following steps:

[0045] S1: Design patterns, use double-sided jacquard knitting upper computer plate-making, design the surface pattern of jacquard knitted fabrics, use computer-making weft-knitting jacquard not only to make the upper material, pattern, color and style changeable and beautiful, but also low-cost The advantages of carbon environmental protection, avoiding the traditional sports uppers made of leather or rubber, resulting in greater product pollution;

[0046] S2: Yarn wrapping treatment, using the conventional yarn wrapping process to wrap the spandex with hot-melt yarn to obtain a hot-melt yarn rack;

[0047]S3: knitting, sending the hot-melt wire frame obtained in S2 together with the conventional knitting yarn into a computerized flat knitting machine to knit a semi-finished double-sided jacquard knitted shoe upper with a preset pattern;

[0048] ...

Embodiment 3

[0055] refer to figure 1 , a method for preparing a double-sided jacquard knitted shoe upper, comprising the following steps:

[0056] S1: Design patterns, use double-sided jacquard knitting upper computer plate-making, design the surface pattern of jacquard knitted fabrics, use computer-making weft-knitting jacquard not only to make the upper material, pattern, color and style changeable and beautiful, but also low-cost The advantages of carbon environmental protection, avoiding the traditional sports uppers made of leather or rubber, resulting in greater product pollution;

[0057] S2: Yarn wrapping treatment, using the conventional yarn wrapping process to wrap the spandex with hot-melt yarn to obtain a hot-melt yarn rack;

[0058] S3: knitting, sending the hot-melt wire frame obtained in S2 together with the conventional knitting yarn into a computerized flat knitting machine to knit a semi-finished double-sided jacquard knitted shoe upper with a preset pattern;

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com