Cutting machine

A cutting machine and frame technology, which is used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor cutting accuracy and large wear of grinding wheels, and achieve the effect of avoiding frequent and non-uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

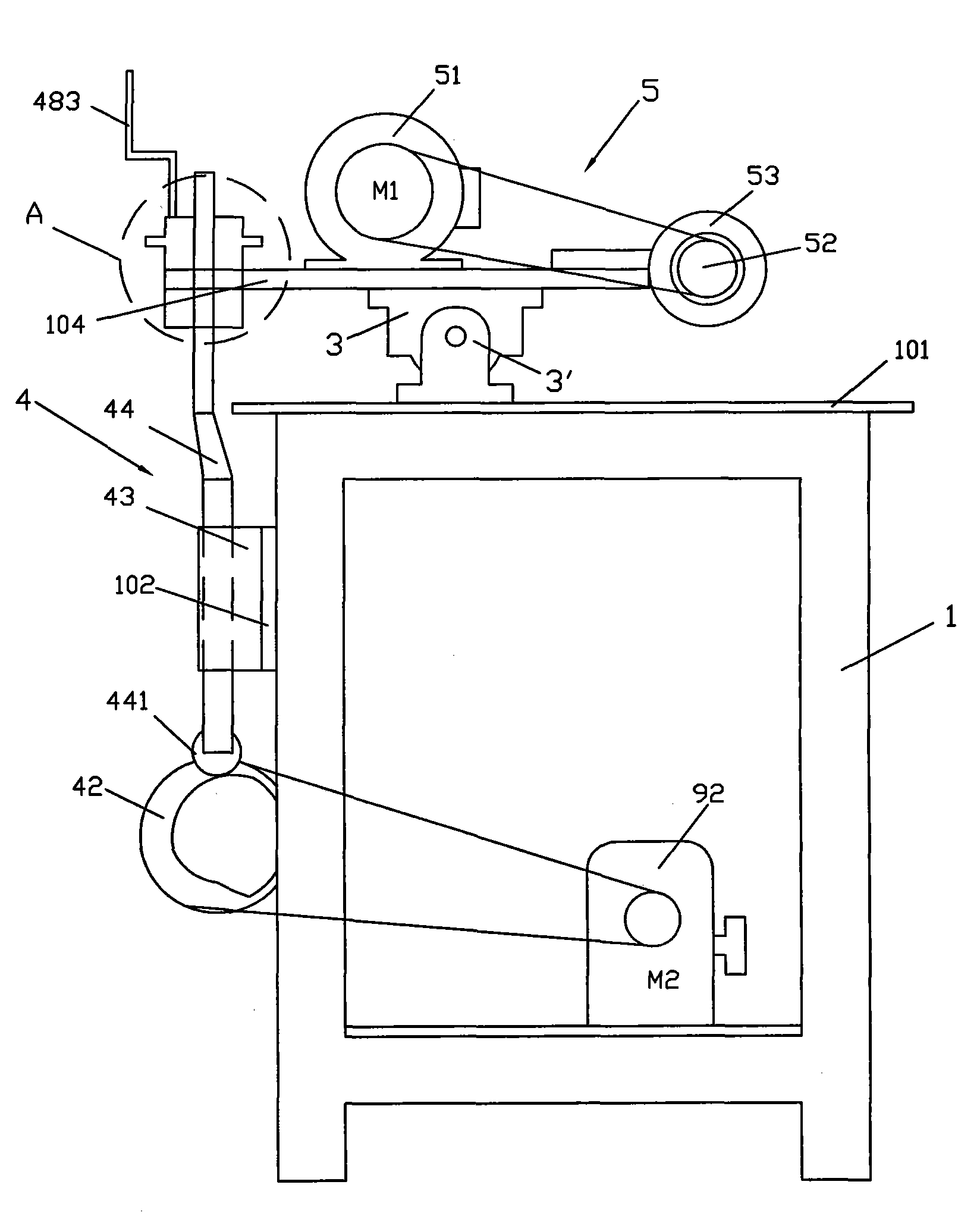

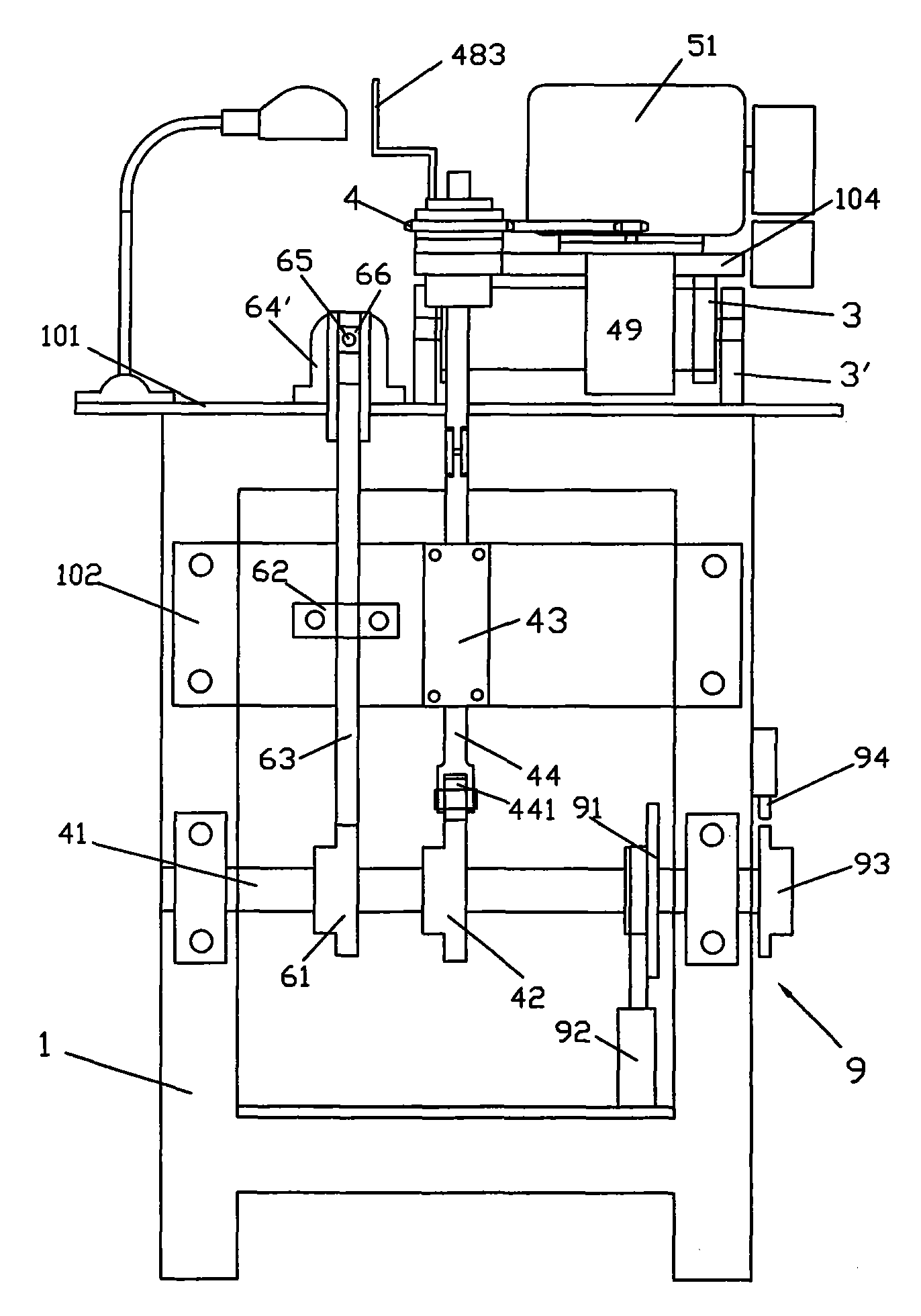

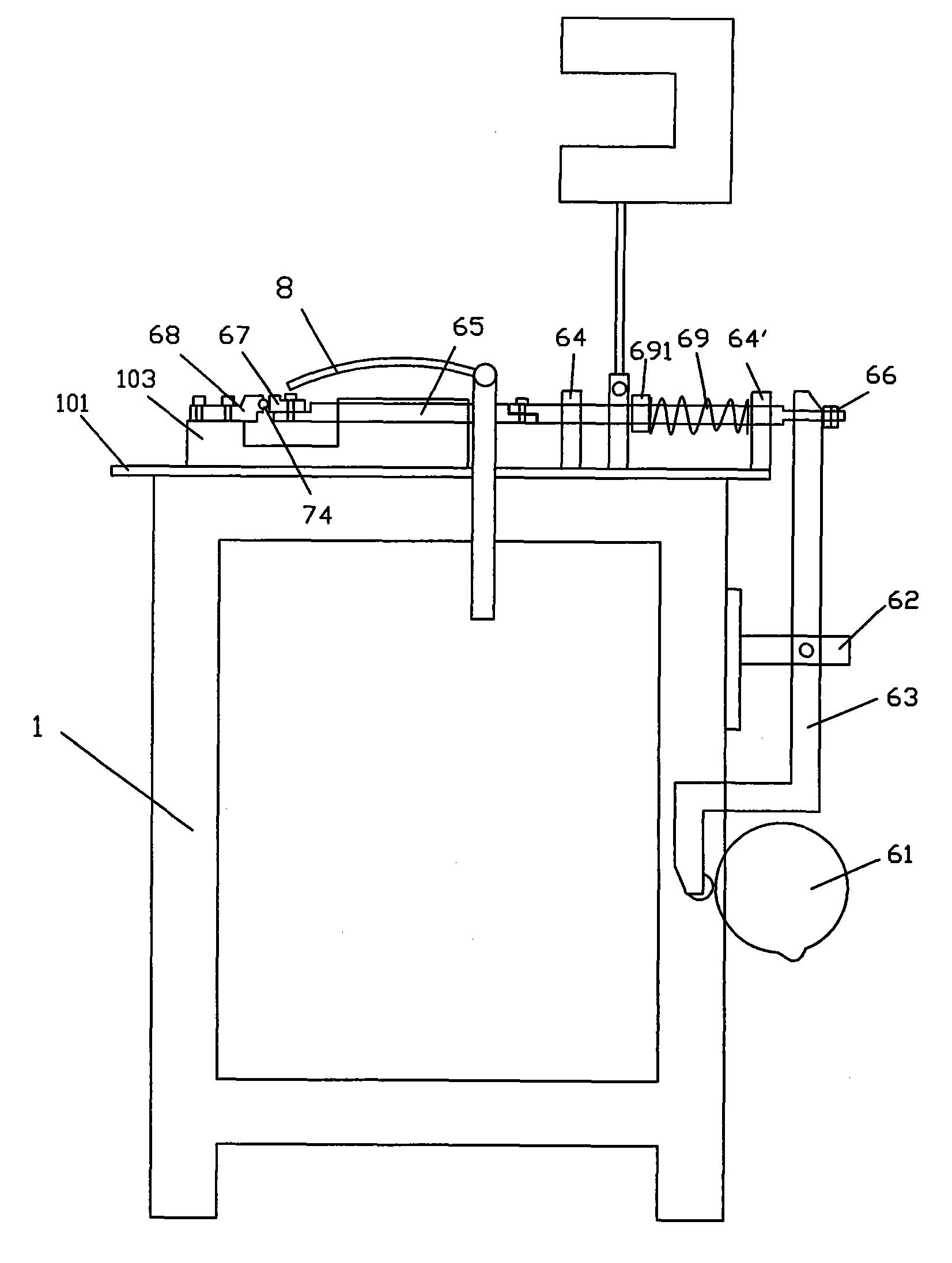

[0026] see Figure 1 to Figure 7 , the cutting machine of the present invention, it comprises, frame 1, establishes a worktable 101 on it, and rear side is provided with a fixed panel 102; Workbench 101 is provided with a clamping seat 103; Upper and lower support 3,3' , the two are pivotally connected, the lower support 3' is fixed on the workbench 101; the upper panel 104 is connected to the upper support 3;

[0027] The depth adjustment mechanism 4 includes, the driving shaft 41 is arranged on the frame 1, and an eccentric wheel 42 is sleeved on it; the ejector rod seat 43 is fixed on the fixed panel 102 of the frame 1; In the rod seat 43, the lower end of the ejector rod 44 abuts against the eccentric wheel 42 on the drive shaft 41 through a roller 441; the support 45 is connected to the upper panel 104; Bearings 451, 452; the upper end of the push rod 44 is inserted in the shaft sleeve 46, and threaded with it; the sprocket 47 and the sprocket seat 48 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com