Optical fiber cleaver

A cutting device and optical fiber technology, which is applied in the coupling of optical waveguide, metal processing equipment, metal processing, etc., can solve the problems of inaccurate optical fiber cross section, inconvenient operation of optical fiber cutting device, and inability to reliably clamp optical fiber, etc., to achieve extended The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

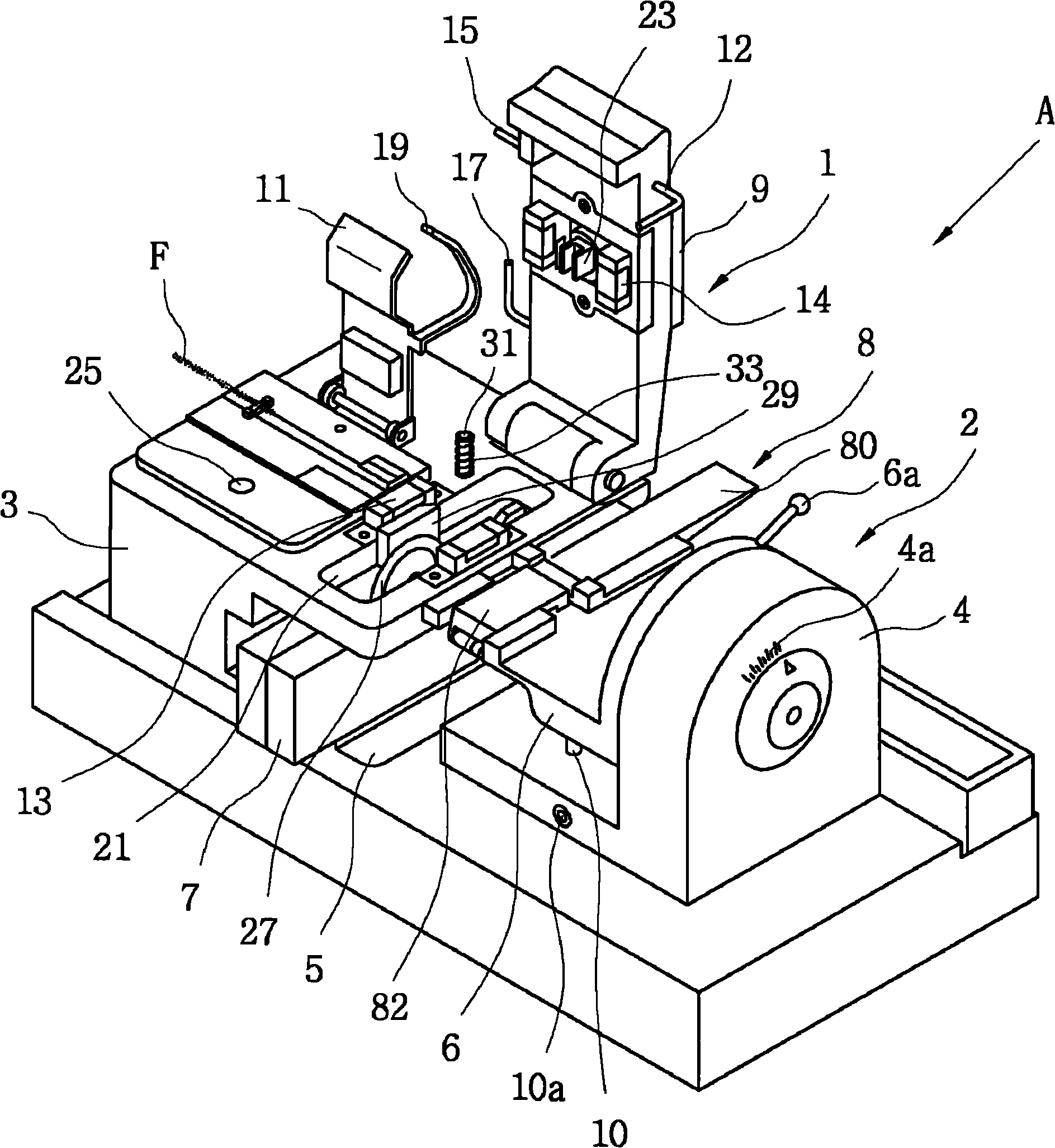

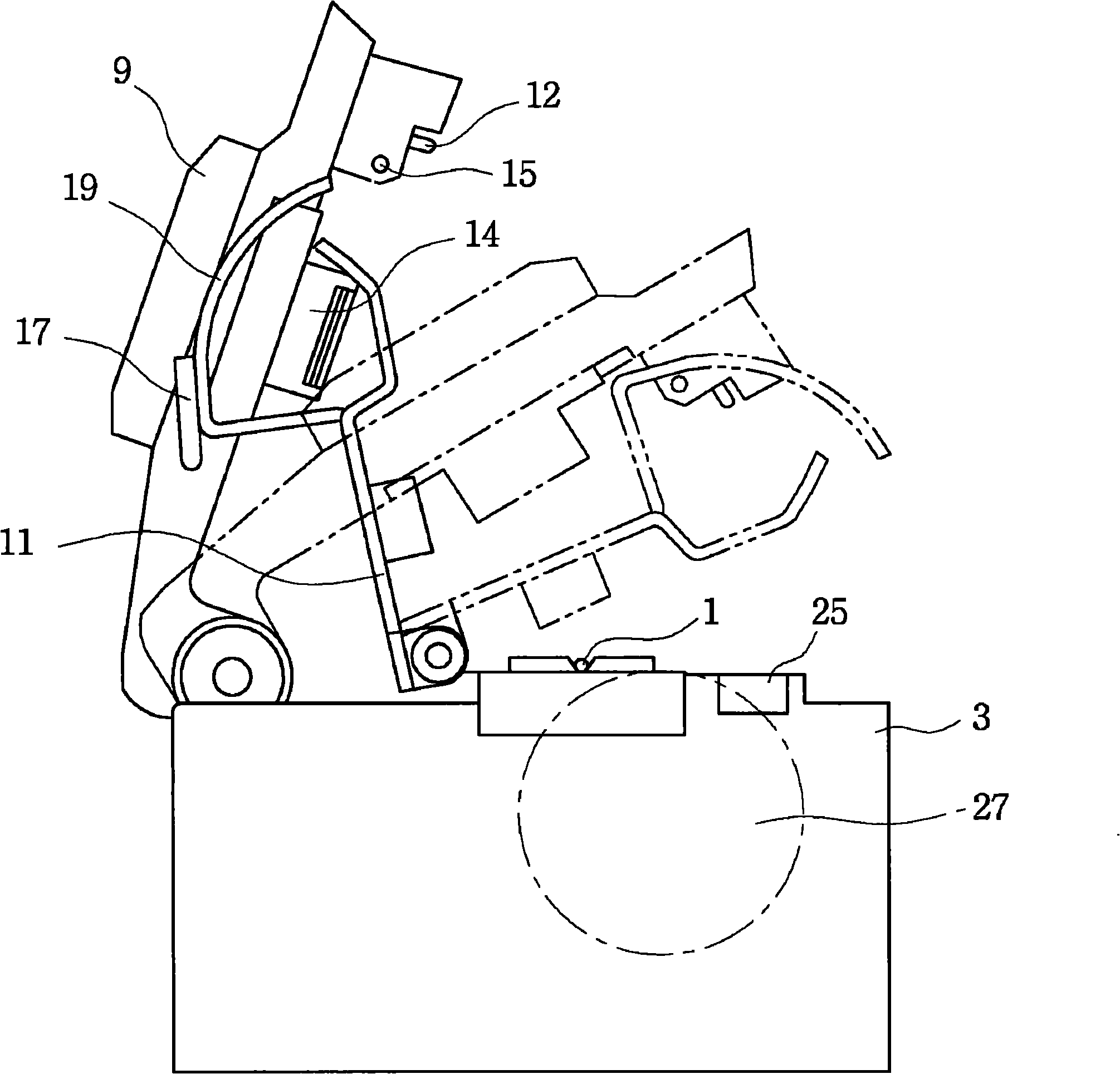

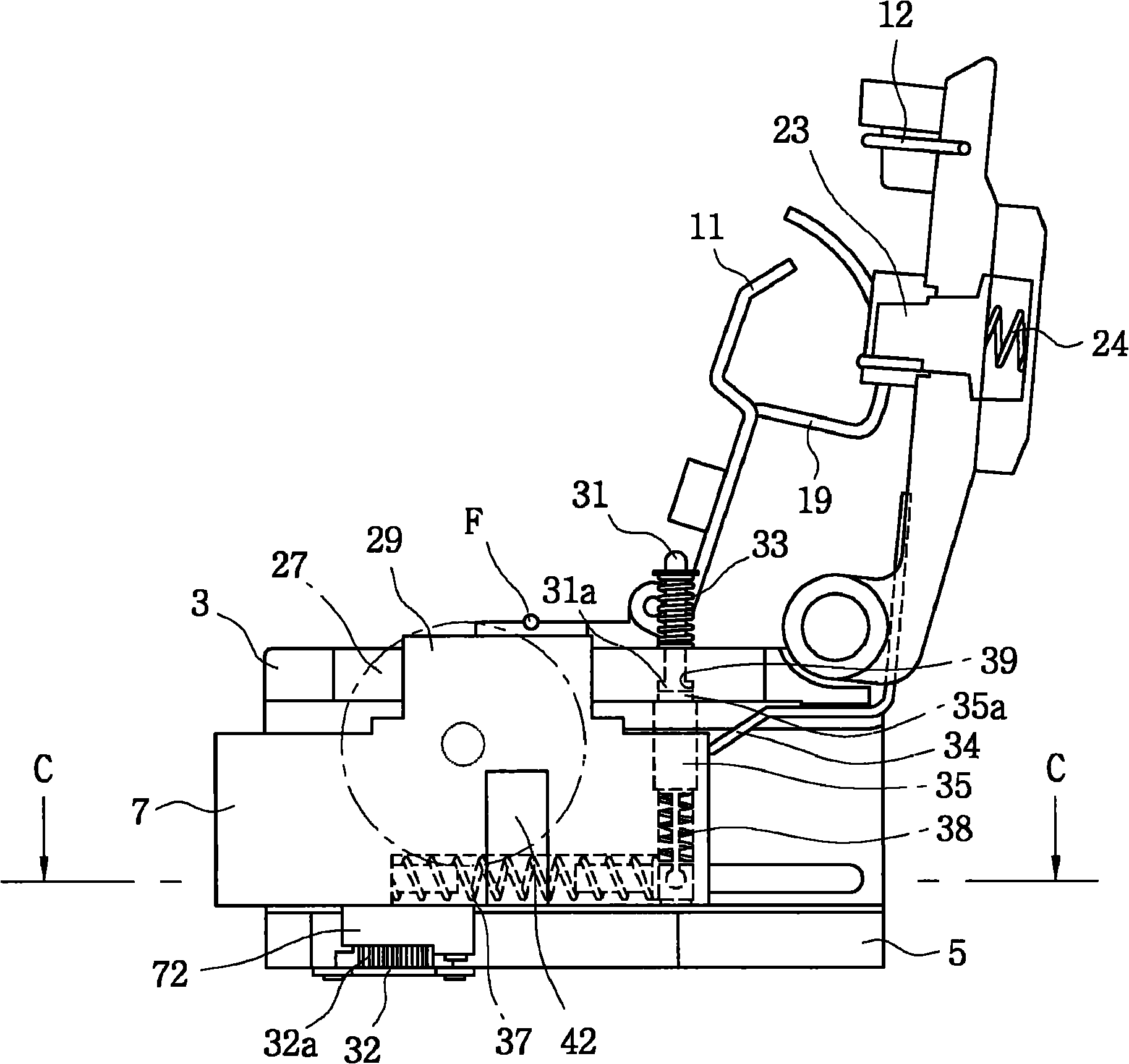

[0034] see figure 1 , The optical fiber cutting device according to the first embodiment of the present invention includes a cutting unit 1 for cutting an optical fiber F and a twisting unit 2 disposed opposite to the cutting unit 1 .

[0035] The cutting unit 1 includes a main body 3 , first and second covers 9 and 11 pivotally mounted on the main body 3 , and a slider 7 provided at one end of the main body 3 so as to be movable on a base 5 .

[0036] The main body 3 has a support 13 , an opening 21 , a magnet 25 and a protruding pin 31 on its upper surface.

[0037] The first cover 9 has a striking member 23 and a clamping block 14 on one surface thereof, and a driving lever 12, a pulling pin 15 and a pushing pin 17 on the opposite side wall thereof.

[0038] The second cover 11 has an arcuate arm 19 on its edge adjacent to the first cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com