Back washing filter

A filter and backwashing technology, which is applied in the direction of gravity filter, fixed filter element filter, filter separation, etc., can solve the problems of filter element bulge, increase the labor intensity of laborers, reduce the service life of filter element, etc., to ensure the cleanliness , to ensure reliable commutation and to protect the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

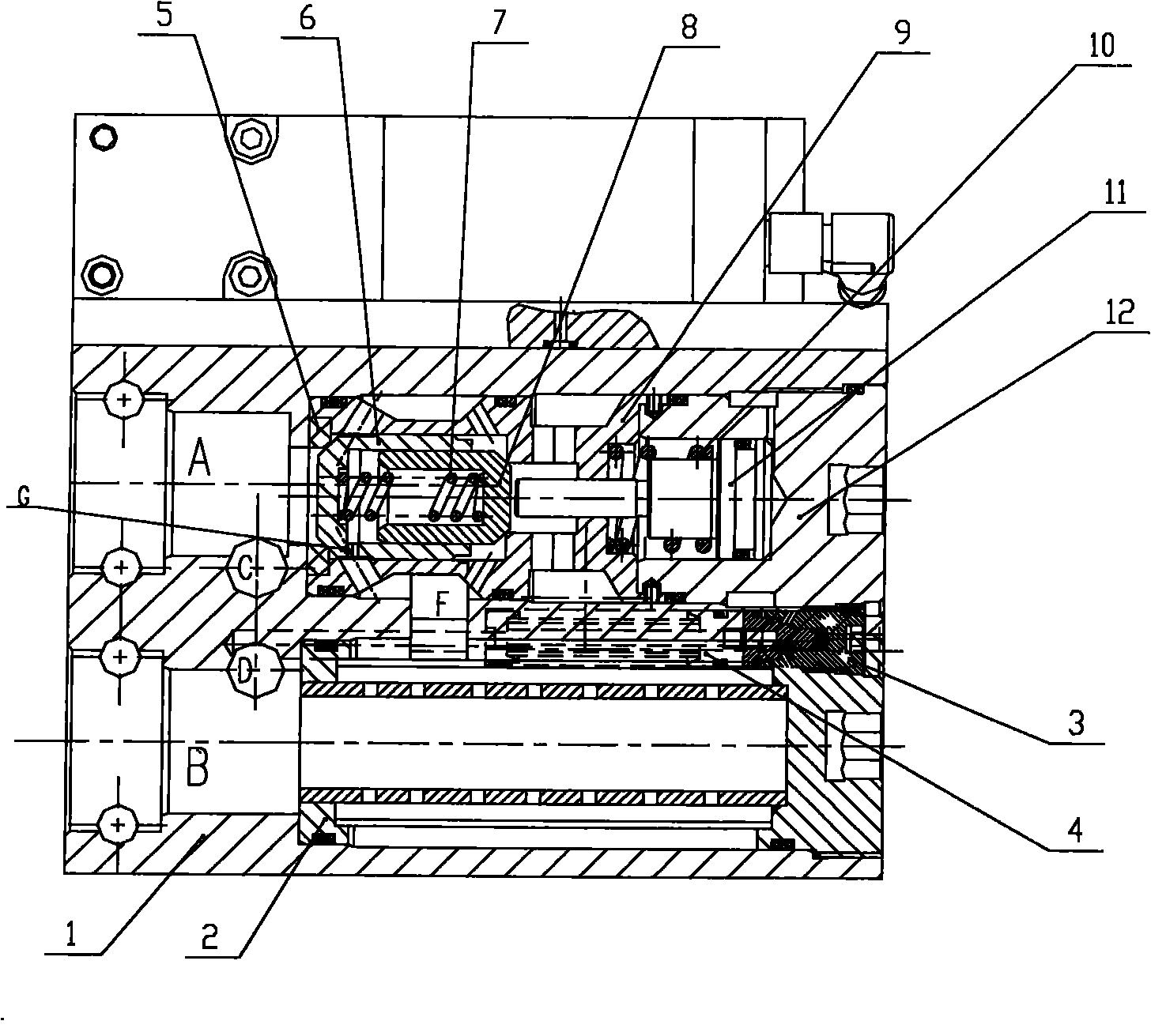

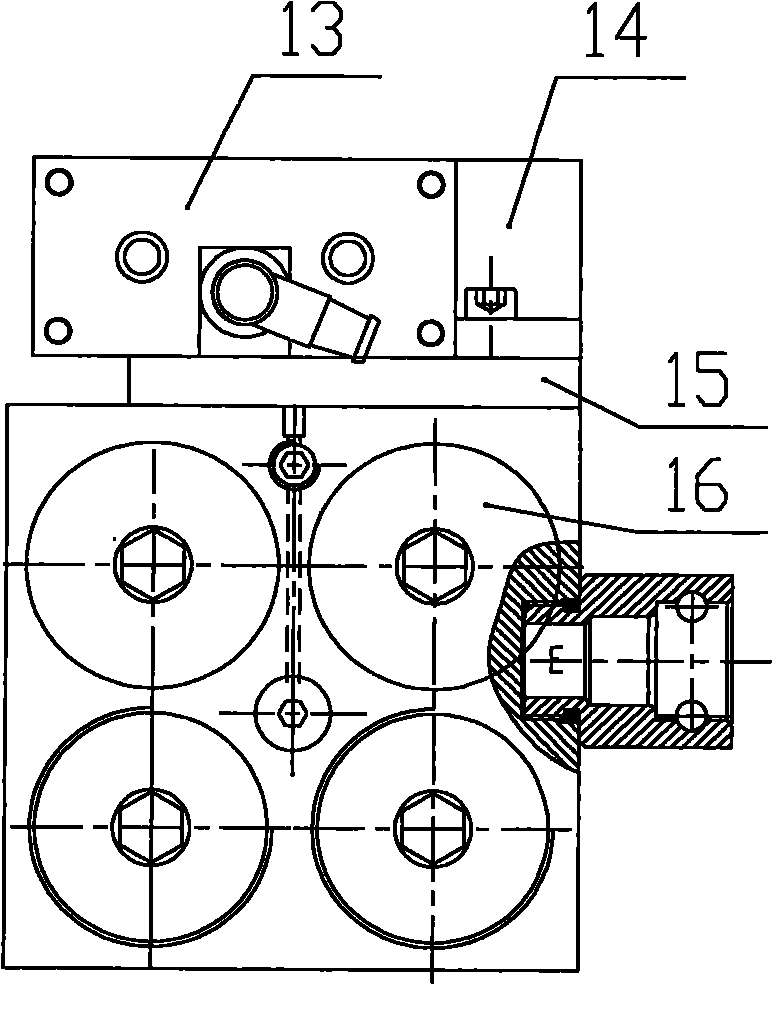

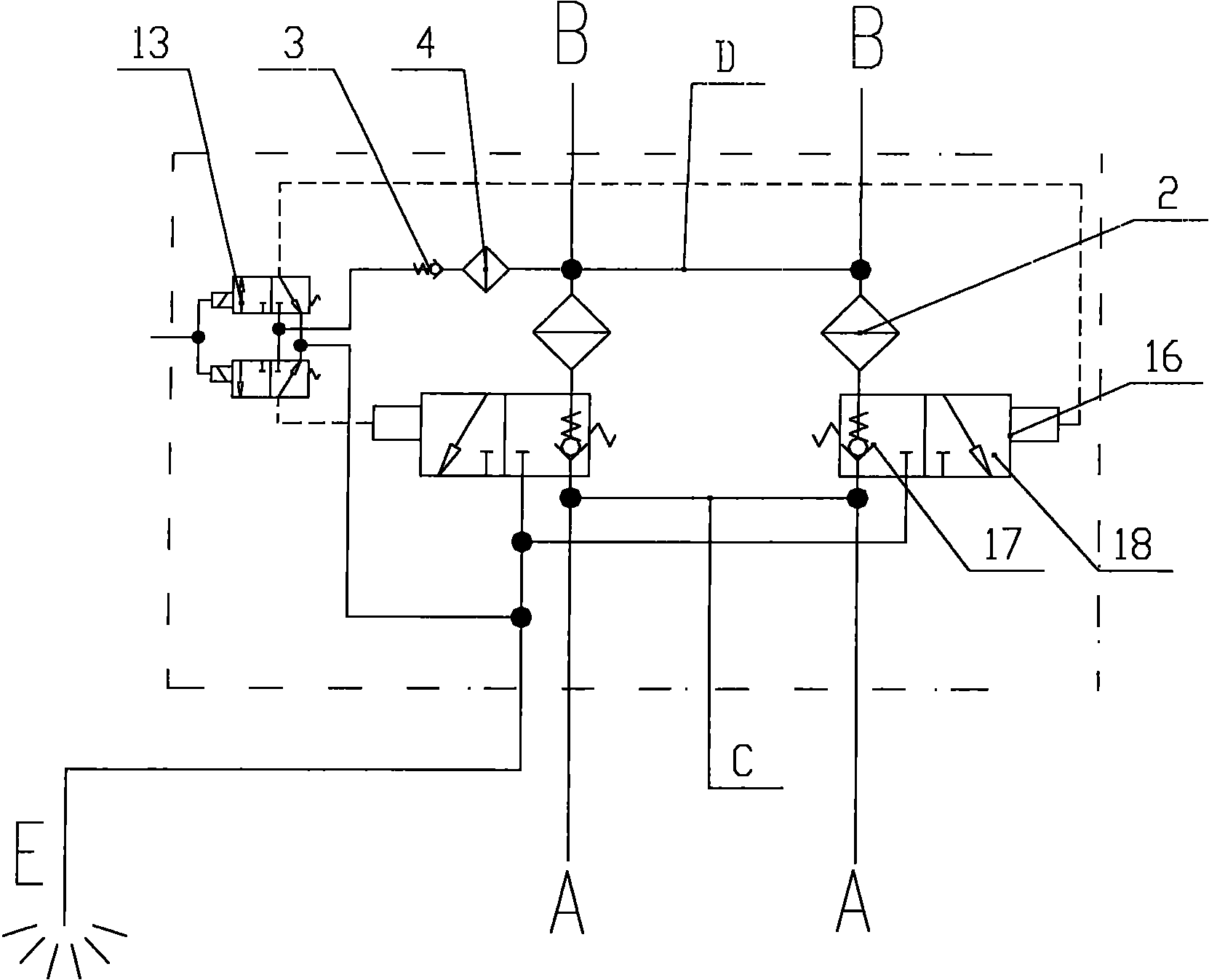

[0014] Backwash filter of the present invention, its preferred embodiment is as figure 1 , figure 2 , image 3 Shown:

[0015] It includes a valve body 1, which is provided with a liquid inlet A, a liquid outlet B, and a sewage outlet E. The valve body 1 is provided with a plurality of valve core assemblies 16, a plurality of filter element assemblies 2, and a valve core assembly 16 There is a communication channel between the filter element assembly 2.

[0016] Specifically, two valve core assemblies 16 and two filter element assemblies 2 may be provided in the valve body 1, the two valve core assemblies 16 are correspondingly provided with two liquid inlets A, and the two filter element assemblies 2 are correspondingly provided with two liquid outlets. Port B, the two liquid inlets A are connected to each other, and the two liquid outlets B are connected to each other.

[0017] The spool assembly 16 includes a liquid inlet spool 6 and a blowdown spool 8 arranged back to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com