Patents

Literature

50results about How to "Reduce the difficulty of process operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

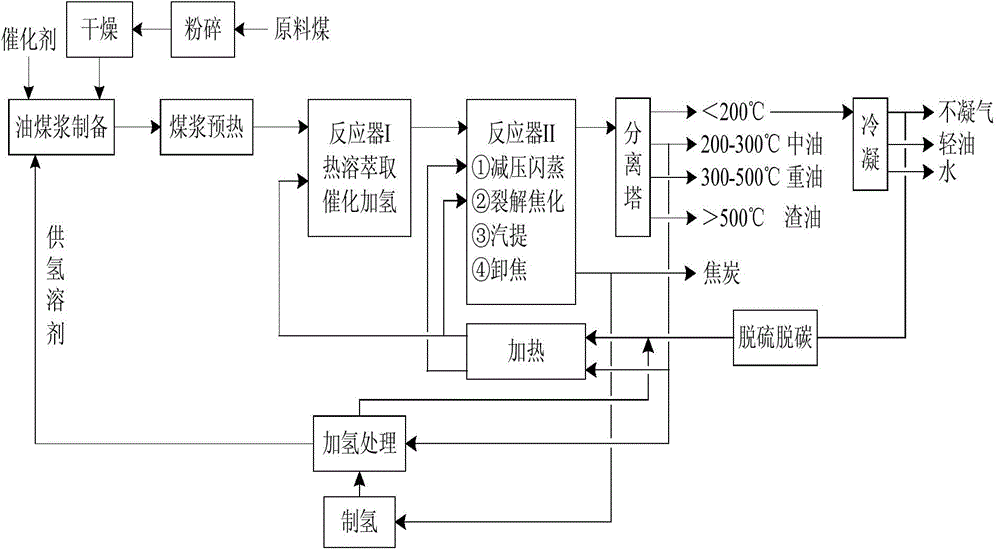

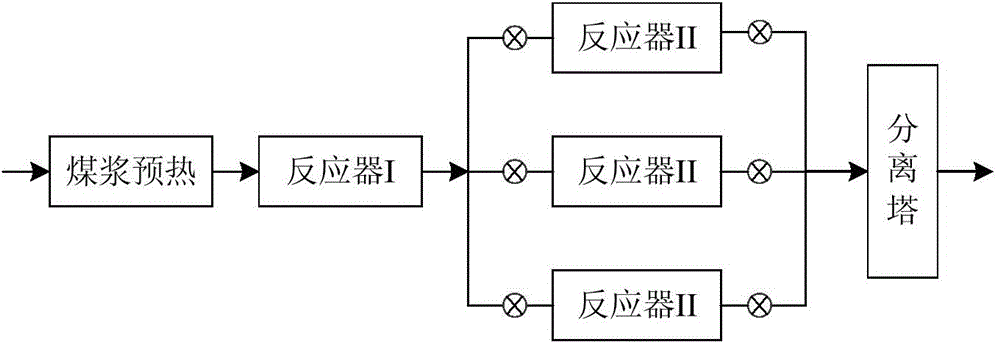

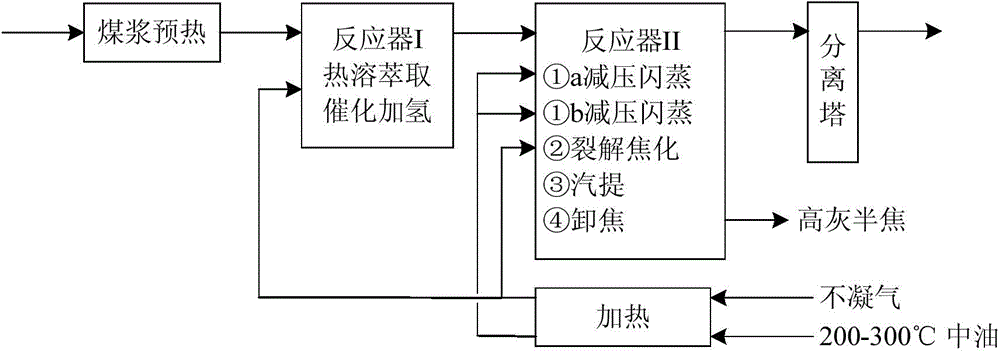

Method for liquifying coal mildly

ActiveCN103555357AIncrease the ratio of hydrogen to carbonReduce the difficulty of process operationLiquid hydrocarbon mixture productionSolventActivated carbon

The invention relates to a method for liquifying coal mildly. The method mainly comprises steps of dry smashing coal samples and mixing with catalyst and hydrogen-donor solvent to form thick liquid; heating and then injecting into a reactor I, carrying out catalytic hydrogenation reaction on coal and hydrogen-donor solvent under mild condition, continuously dissolving out soluble components in products and coal; then injecting into a reactor II, flash distilling part of the product and solvent, rising temperature so as to split and coke left products to generate low boiling point compound and coke, wherein the coke can be used for preparing activated carbon and hydrogen. After the product which is vacuum flashed and purged through steam stripping is separated, different components are obtained, the component below 200 DEG C is condensed so as to obtain light oil, non-condensed gas and water, 200-300 DEG C component is condensed so as to obtain middle oil, after hydrotreating, the middle oil can be used as hydrogen-donor solvent, 300-500 DEG C component is condensed so as to obtain heavy oil which can be used for preparing chemicals or advanced carbon materials, and the component above 500 DEG C is condensed so as to obtain residual oil which can be used for preparing advanced carbon materials. The method has mild reaction conditions, the reactor is coupling, the efficient of the equipment is high, the yield of liquid product is high, the investment of the equipment is low, and the energy conversion efficiency is high.

Owner:EAST CHINA UNIV OF SCI & TECH +1

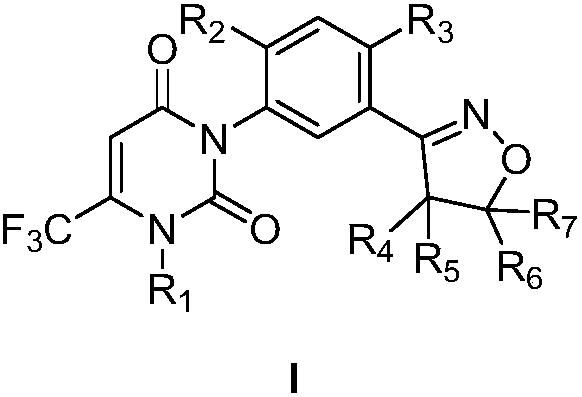

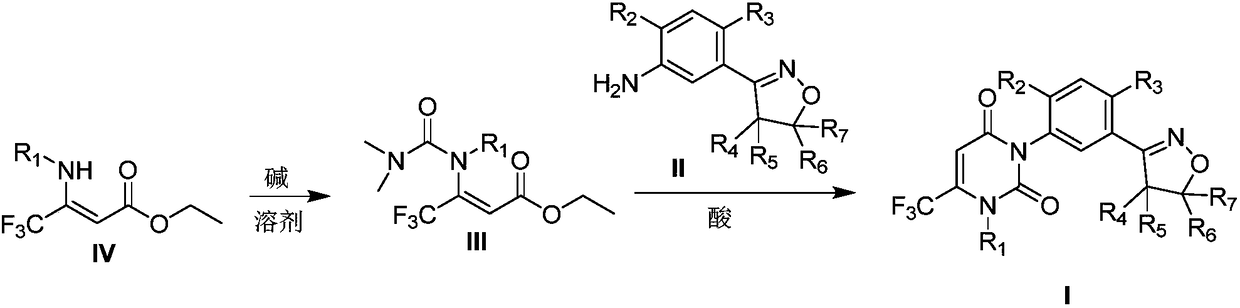

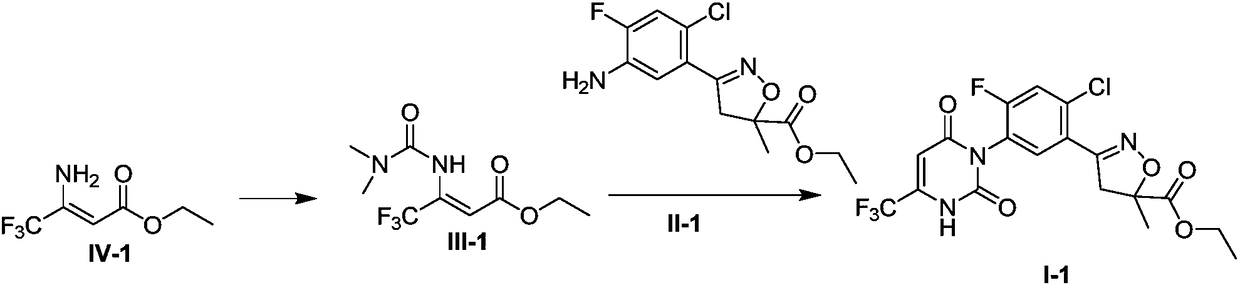

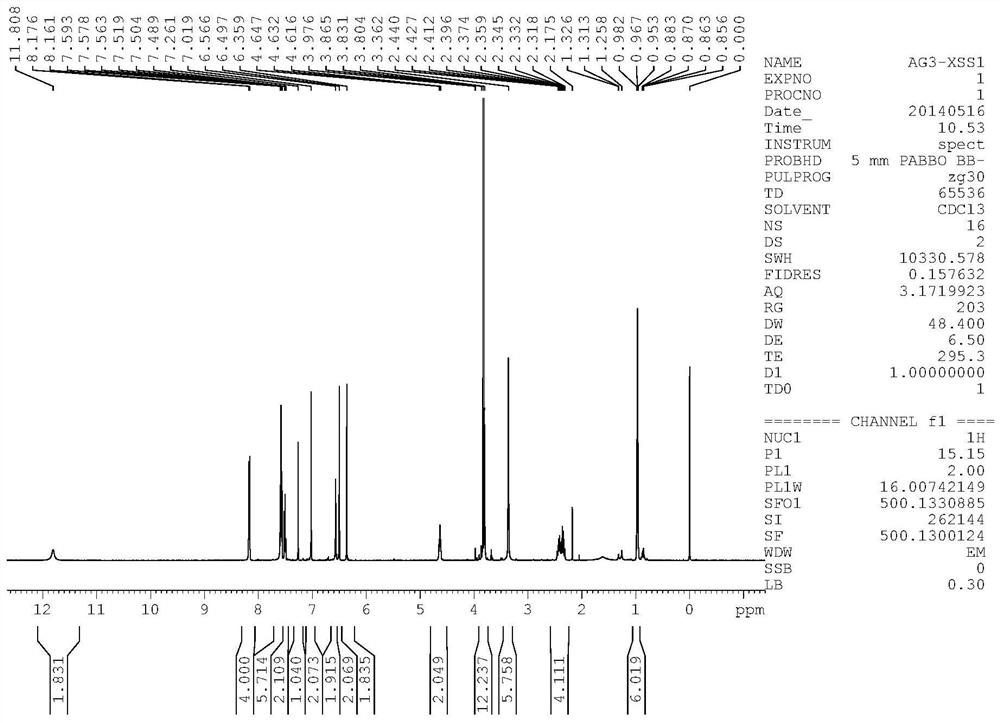

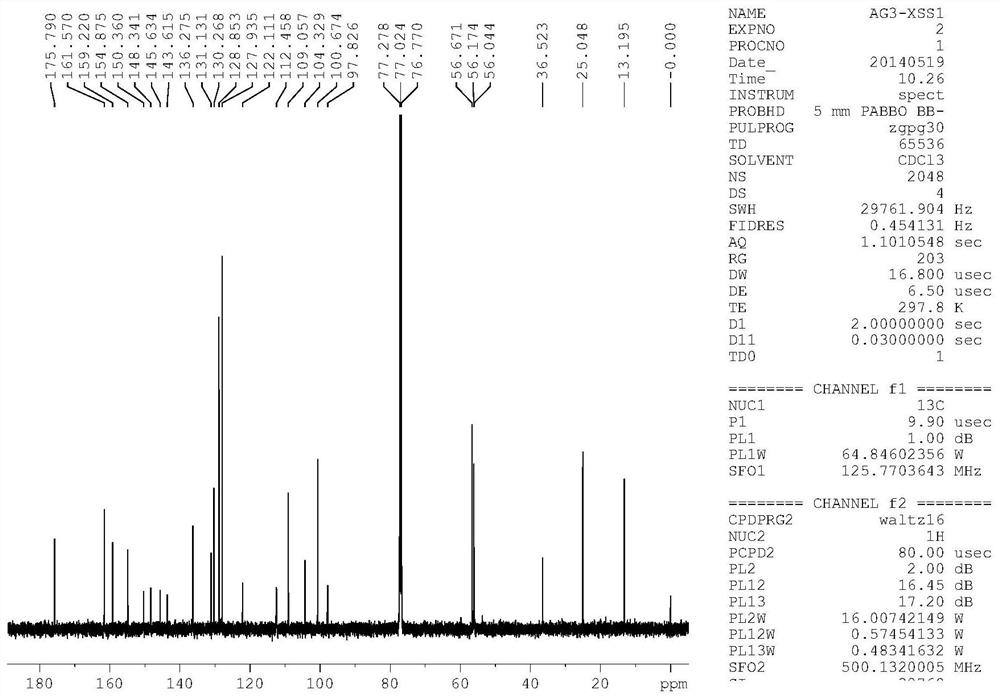

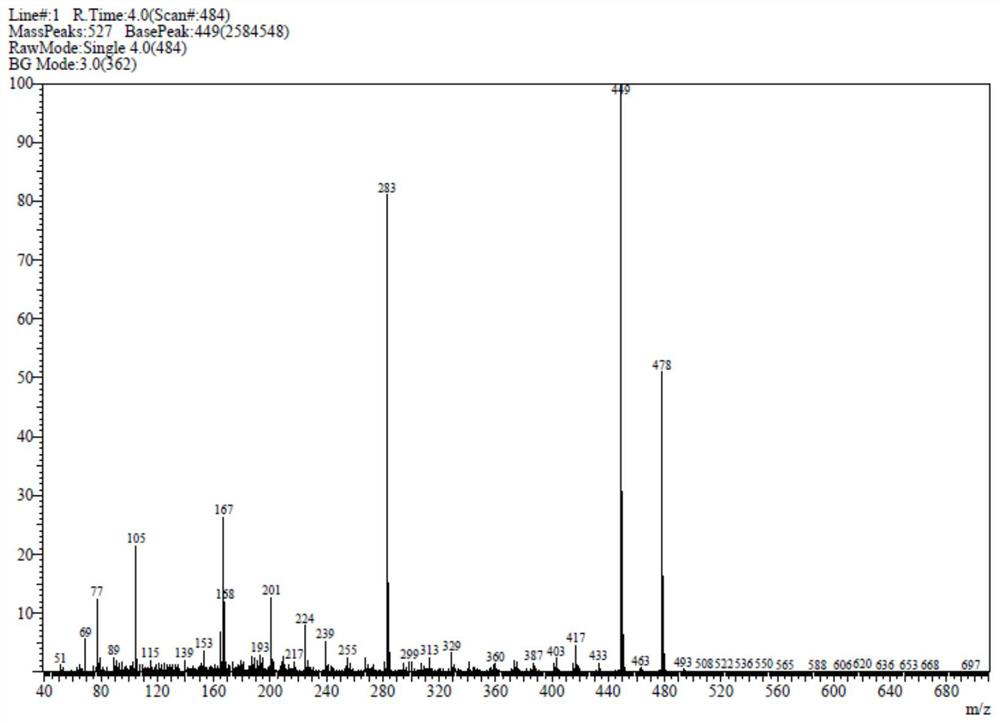

Preparation method for isoxazoline-containing uracil compound

The invention provides a preparation method for an isoxazoline-containing uracil compounds, belonging to the field of organic synthesis. The preparation method comprises the following steps: reactinga compound IV with an alkali in an organic solvent, then adding N,N-dimethylformyl chloride for a reaction so as to obtain a compound III and then reacting the compound III with a compound II in acidto obtain the target compound I. A reaction formula is as described in the specification. Each group in the formula is as described in the specification. The preparation method provided by the invention can avoid the use of expensive reagents or high-toxicity methylation reagents, effectively reduces cost and is easy for industrial production.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

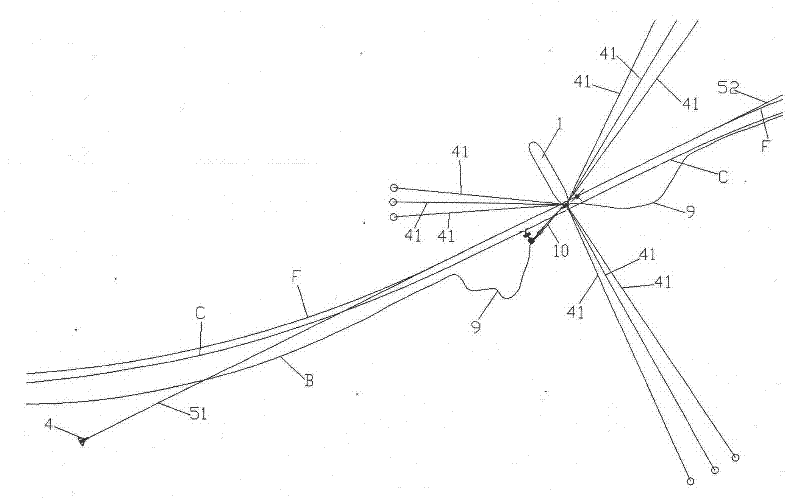

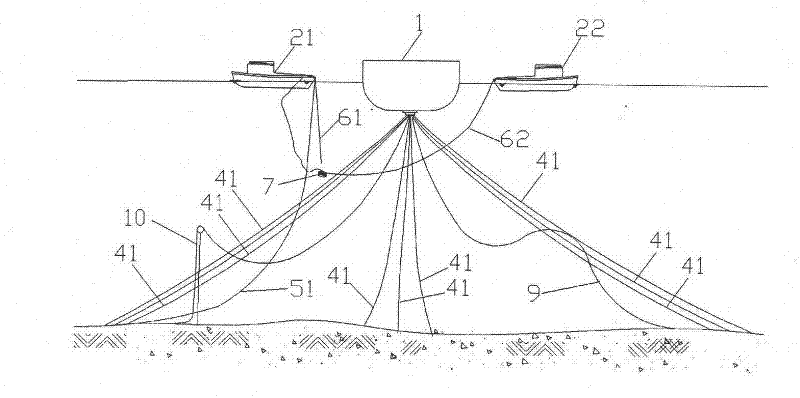

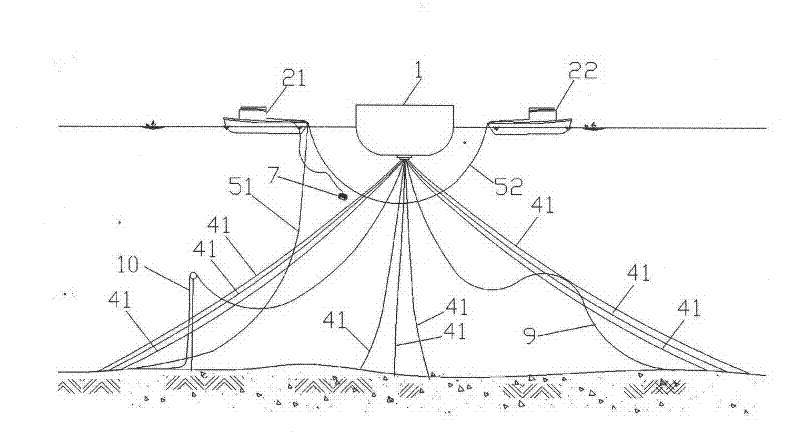

Laying process of subsea pipeline crossing floating production and storage device system

ActiveCN102269296AWill not affect normal production operationsSimple processPipe laying and repairOcean bottomSubmarine pipeline

The invention provides a laying process for a submarine pipeline traversing floating type production oil-storing device system. The laying process comprising the following steps: installing a starting anchor, laying a starting cable, laying a traversing part pipeline, a traversing part drag-traversing floating type production oil-storing device system, a traversing part pipeline tension test and laying a submarine pipeline; and the laying process is adopted to realize the submarine pipeline laying task of the traversing floating type production oil-storing device system without influencing the normal production of the floating type production oil-storing system, thus being convenient in the submarine pipeline laying task.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Chemical method for synthesizing ephedrine

ActiveCN101570492ASimple production processEasy to useOrganic compound preparationAmino-hyroxy compound preparationChemical synthesisOrganic acid

The invention relates to a chemical method for synthesizing ephedrine. In the technology, (+ / -)alpha-methylaminophenylpropanone hydrochloride is taken as a raw material and reduced to the mixtures of (+ / -)ephedrine and (+ / -)pseudoephedrine by a proper reducing agent; the (+ / -)ephedrine is separated, and the l-ephedrine or l-ephedrine hydrochloride is separated by using chiral organic acid as a resolving agent. The method enjoys simple technology, less equipment investment, less environment pollution, less hazardous and poisonous chemical reagents which are used and the like.

Owner:QINGHAI LAKE PHARMA COMPANY

Method for enzymatically extracting rhodomyrtus tomentosa anthocyanidin by means of ultrasonic waves assisting in biological compound enzyme

InactiveCN109022513AHelp brokenEasy extractionOrganic chemistryFermentationRHODOMYRTUS TOMENTOSA FRUITUltrafiltration

The invention discloses a method for enzymatically extracting rhodomyrtus tomentosa anthocyanidin by means of ultrasonic waves assisting in a biological compound enzyme. According to the method, firstly, rhodomyrtus tomentosa fruits are mashed into pulp, then the biological organized enzyme is added for enzymolysis, then through ultrasonic wave assistant extraction and centrifugation, supernate iscollected, ultrafiltration and concentration are conducted, and finally, a concentrated solution is subjected to spray drying to obtain the rhodomyrtus tomentosa anthocyanidin; the biological organized enzyme is a compound of acid cellulase, glucoamylase and tannase; meanwhile, blueberry anthocyanidin extracted by means of biological organized enzyme enzymolysis and ultrasonic wave assistant extraction is high in purity, low in cost and simple and convenient to operate; by means of citric acid, the stability of the anthocyanidin is improved, and anthocyanidin loss caused by oxidation of polyphenol and enzymes is effectively controlled; finally, the efficiency of extracting the anthocyanidin reaches 90% or above.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

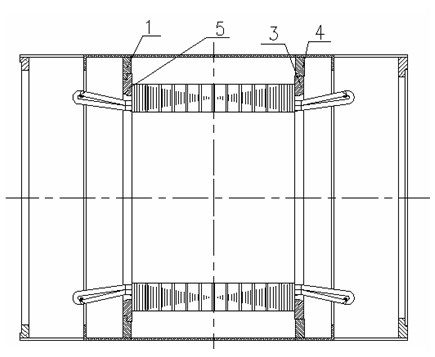

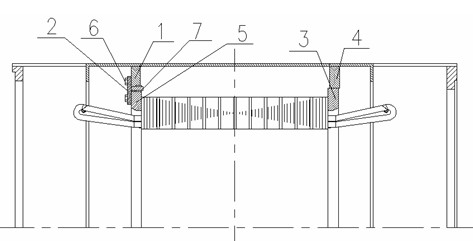

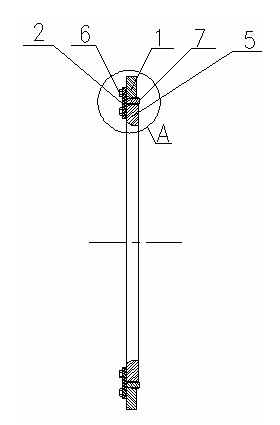

Mode and device for fixing stator and base of motor

ActiveCN102386722AEasy accessEasy to fixManufacturing dynamo-electric machinesInterference fitEngineering

The invention discloses a mode and device for fixing a stator and a base of a motor. The base is internally provided with a base front clapboard and a base rear clapboard, the stator is provided with a stator front clamping ring and a stator rear clamping ring, the base front clapboard and the stator front clamping ring are fixed, the base rear clapboard and the stator rear clamping ring are fixed. The fixing mode is characterized in that the base front clapboard and the stator front clamping ring are fixedly connected by virtue of bolts, and the base rear clapboard and the stator rear clamping ring are fixed by virtue of the bolts or are connected in an interference fit manner. According to the invention, the hidden dangers that the traditional fixing of the stator and the base of the motor is not firm and the stator of the motor is damaged are solved, and a mode and device for fixing the base and stator of the motor, which can eliminate the hidden dangers, provide reliable fastening for the stator, reduce process operational difficulty, be beneficial to mass production of the motor and can avoid secondary damage to the stator when the stator operates, are provided.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

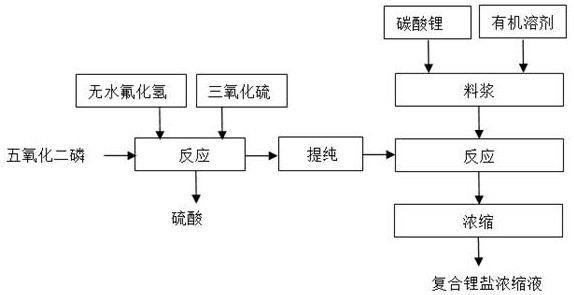

Preparation method of composite lithium salt concentrated solution

InactiveCN111924860AShort processImprove reaction efficiencyPhosphorus halides/oxyhalidesLithium hexafluorophosphateLithium carbonatePhosphoric acid

The invention provides a preparation method of a composite lithium salt concentrated solution. The method comprises the following steps of: putting lithium carbonate into an organic solvent in an inert atmosphere to obtain slurry, and introducing phosphorus pentafluoride gas into the slurry to react to obtain a composite lithium salt concentrated solution. According to the preparation method provided by the invention, the composite lithium salt concentrated solution containing lithium difluorophosphate and lithium hexafluorophosphate can be prepared by taking phosphorus pentafluoride and lithium carbonate as raw materials through a gas-solid reaction under a non-aqueous solvent condition and a one-step method, has the advantages of short process flow, no side reaction, high reaction efficiency, good product performance, high yield and no emission of three wastes, and is short in process production period and suitable for industrial production.

Owner:湖南法恩莱特新能源科技有限公司

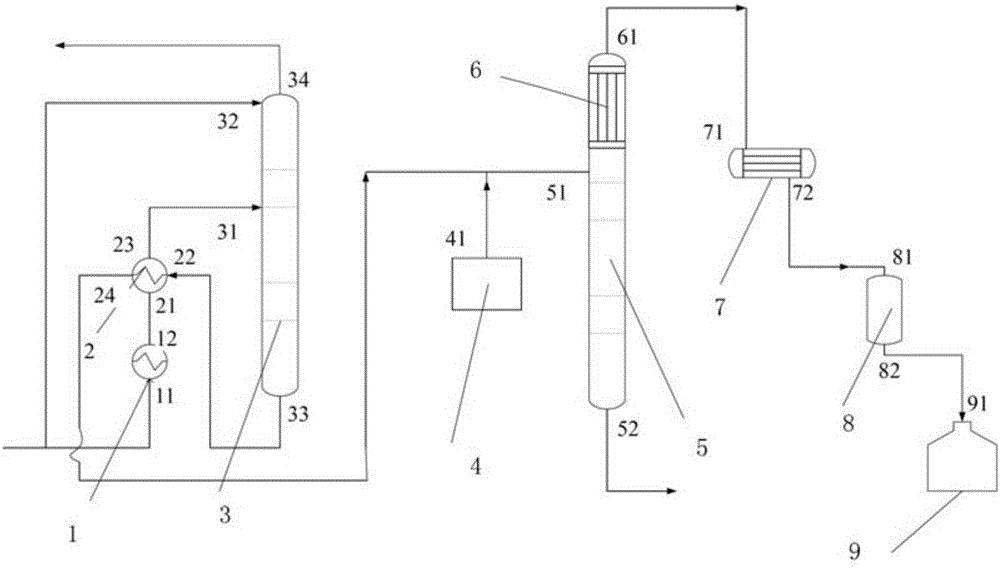

Benzene hydrogenation wastewater desulfurization and deamination treatment method aiming at improving deamination and treatment device applying same

InactiveCN105884106AQuality improvementReduce consumptionMultistage water/sewage treatmentWater/sewage treatment by neutralisationBenzeneWastewater

The invention relates to a benzene hydrogenation wastewater desulfurization and deamination treatment method and device. Alkaline liquid is added before deacidification tower kettle liquid enters a deamination tower to fix sulfur ions left in wastewater after desulfurization, so that influence on quality of ammonia water or liquid ammonia due to the fact that the sulfur ions left in the wastewater enters ammonia in a form of hydrogen sulfide in the process of ammonia distilling is avoided. On the basis of a petrochemical desulfurization and deamination process, the whole desulfurization and deamination process is simplified, operation difficulty is lowered, and equipment investment is saved.

Owner:TANGSHAN XUYANG CHEM IND CO LTD

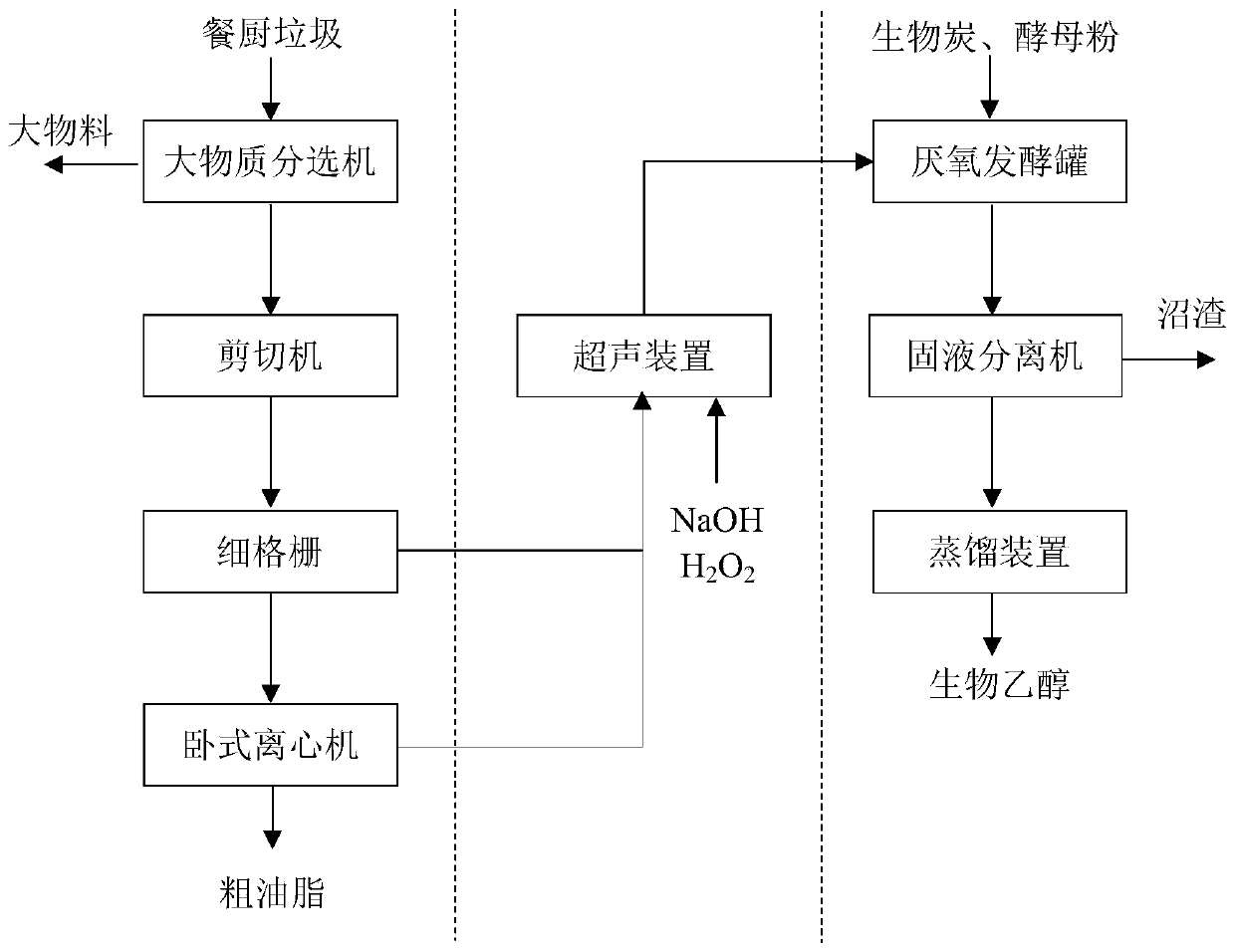

Method for producing bioethanol through anaerobic fermentation of kitchen waste

InactiveCN111118069APromote decompositionImprove decomposition abilityMicroorganism based processesFermentationProcess engineeringHydrolytic Process

The invention discloses a method for producing ethanol through anaerobic fermentation of kitchen waste. The method comprises the following steps: carrying out sorting pretreatment on the collected andtransported kitchen waste; carrying out ultrasonic / alkali / H2O2 combined pretreatment on the sorted and oil-extracted kitchen waste to promote the hydrolysis process of the kitchen waste; and carryingout anaerobic fermentation on pretreated slurry, and conducting separating after fermentation to obtain the bioethanol. According to the method, the ethanol yield of the anaerobic fermentation of thekitchen waste is increased; and meanwhile, preparation process is simplified, and a technical method with higher feasibility is provided for recycling of the kitchen waste.

Owner:长沙工研院环保有限公司

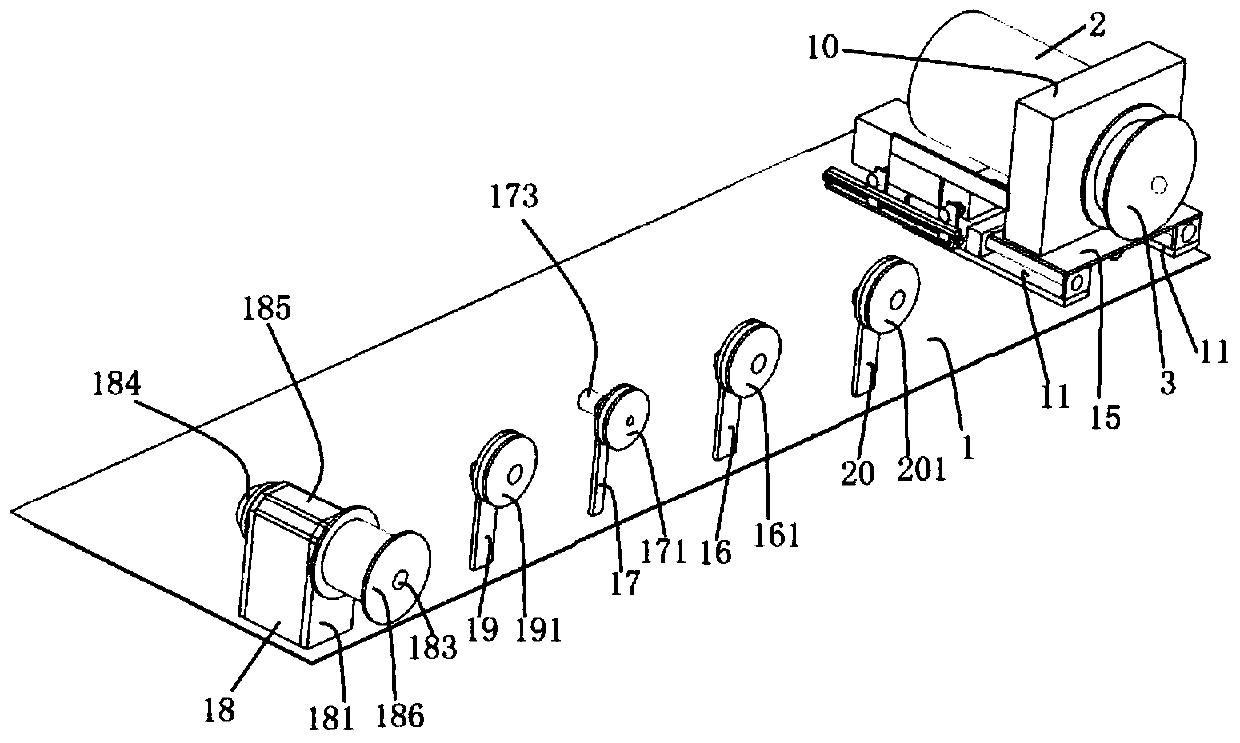

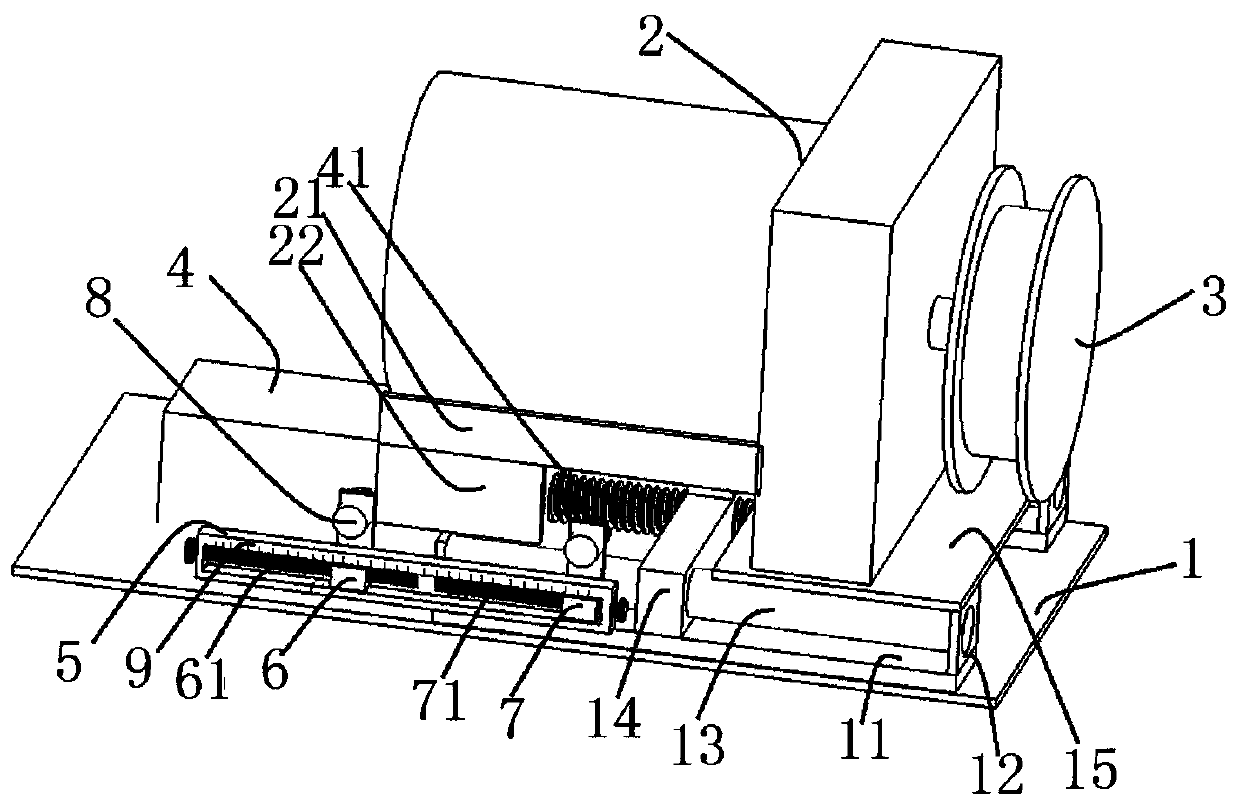

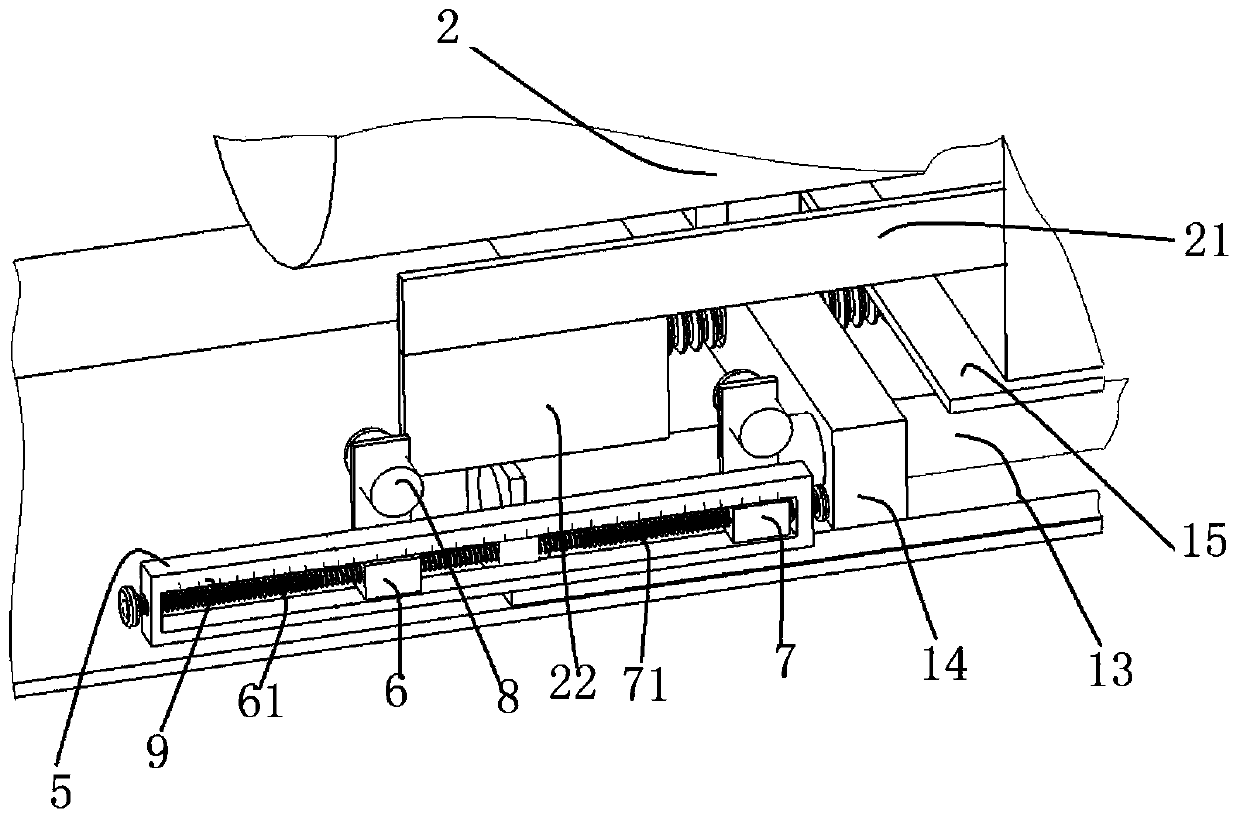

Full-automatic wire tension control rewinding machine

PendingCN110155808AReduce the difficulty of process operationImprove product qualityFilament handlingWire tensionEngineering

The invention discloses a full-automatic wire tension control rewinding machine. The machine comprises a bottom plate, wherein the bottom plate is provided with a wire pay-off device, the wire pay-offdevice is provided with a material wire coil in an inserting mode, and a material wire in the material wire coil winds around a positioning mechanism, a tension sensor mechanism, a speed measuring mechanism and a flat cable positioning mechanism in a sequential mode, and then wound on a wire take-up device. The wire take-up device, the tension sensor mechanism and the speed measuring mechanism ismatched with the wire pay-off device. The real-time tension of the wire material is detected through a tension sensor, thus transiting the data to a tension controller, and then the tension controller controls a real-time output torque of a magnetic powder brake, so that the wire pay-off tension can be stably controlled; in addition, by using the tension sensor and the magnetic powder brake, thetension, stress, straightness and flatness of the wire material can be realized; further more, with the tension sensor and the magnetic powder brake matched with the speed measuring mechanism, the arrangement of winding wire of the material wire coil is compact with the tension and stress being uniform, thus improving production efficiency as well as product quality, and the problems of messed wire, broken wire, pressed wire, over looseness of wire take-up, coil explosion and the like occurring during stop of turning and coil separation can be solved.

Owner:CHENGDU HONGBO INDAL

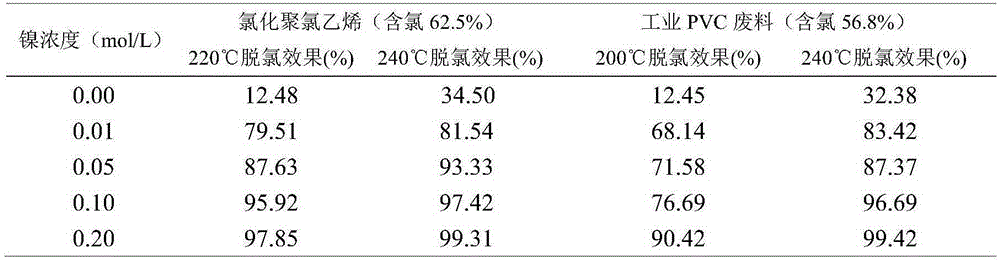

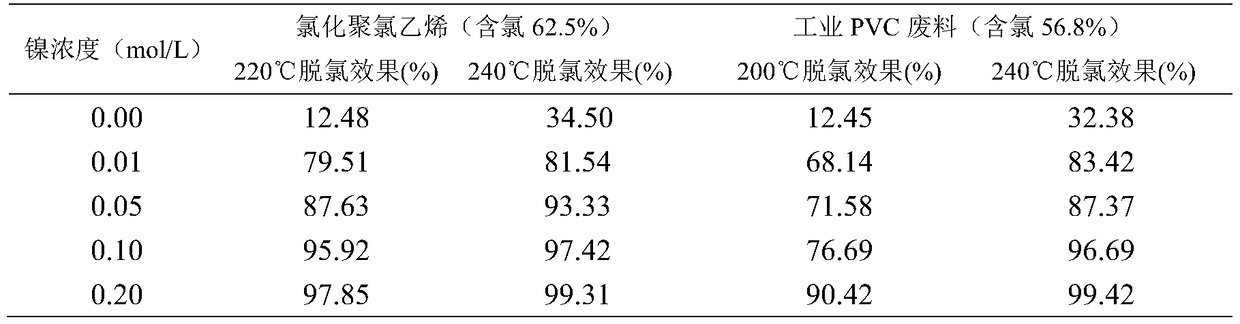

Method for efficiently dehalogenating waste plastics

ActiveCN105295088APromote conversionIncrease the number ofPlastic recyclingReaction temperatureEthyl Chloride

The invention discloses a method for efficiently dehalogenating waste plastics. The method comprises the following three steps: 1. quenching and tempering: adding an alkaline chemical raw material to the waste plastics, then adding a solution of a Ni<2+> chemical raw material / waste material and stirring and uniformly mixing the materials; 2. hydrothermal treatment: carrying out hydrothermal treatment on the prepared waste plastics at 200-240 DEG C for 10-60 minutes; 3. dehydration: carrying out solid-liquid separation on a mixture obtained after hydrothermal treatment, thus obtaining coke. The method has the beneficial effects that the function of Ni<2+> in plastic dehalogenation is confirmed for the first time; the method has the characteristics that the adding proportion of the alkaline chemical raw material is extremely small; the cost is low; the process is simple; the halogen removal efficiency is high; the reaction temperature is low; the time is short; the halogen containing rate of the waste plastics is reduced to about 0 from 56.8-74%; secondary pollution can not be caused; the plastics excluding halogen and some chemical raw materials after separation can be recycled, thus avoiding the problems of chlorine corrosion and dioxin pollution during halogen-containing plastic burning and providing beneficial conditions for harmless treatment and recycling of the halogen-containing plastics.

Owner:CHINA UNIV OF MINING & TECH

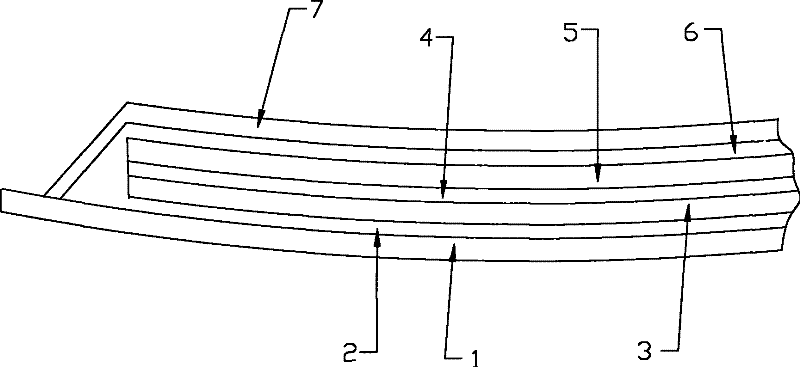

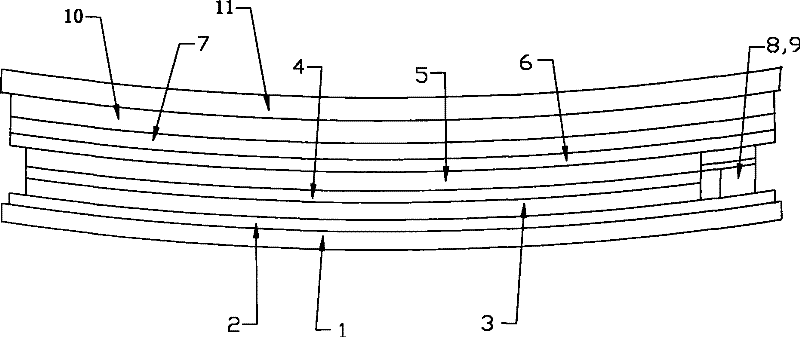

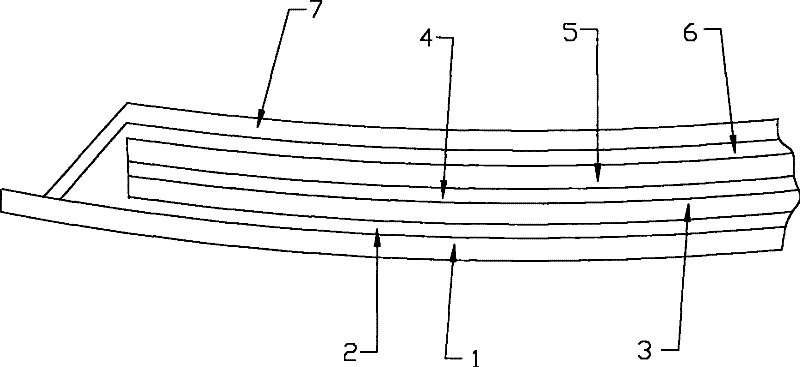

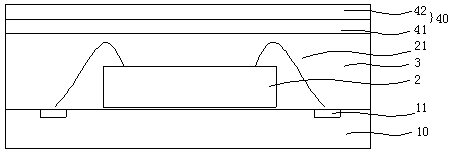

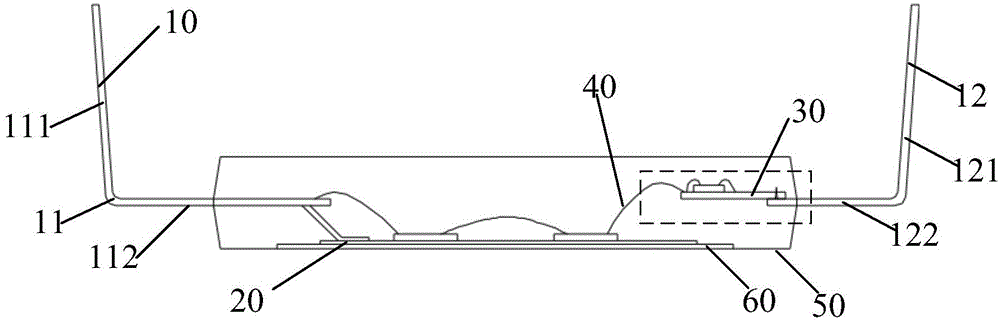

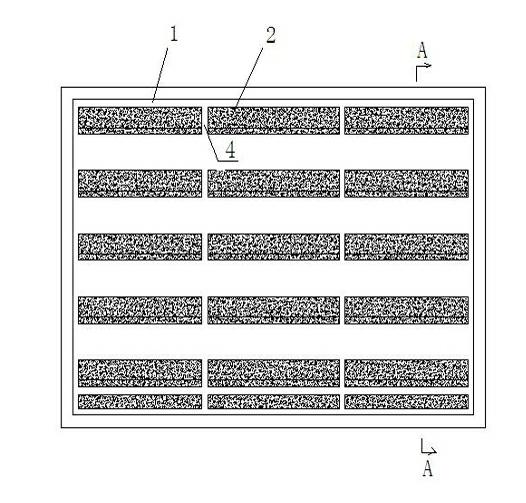

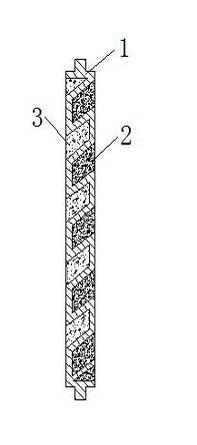

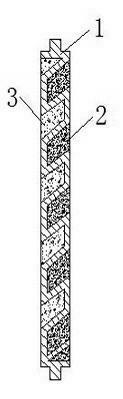

Dimming glass and manufacturing method thereof

ActiveCN101725316BLittle changeReduce the difficulty of process operationStatic indicating devicesLaminationLiquid crystalMaterials science

The invention provides dimming glass and a manufacturing method thereof. The dimming glass comprises glass, a first adhesive layer, a first conducting layer, a polymer dispersed liquid crystal layer, a second conducting layer, a second adhesive layer and a hard film layer which are orderly stacked. In the dimming glass provided by the invention, the polymer dispersed liquid crystal layer is clamped between the glass and the hard film layer, only one piece of glass is required instead of two pieces of glass, and the requirements on the surface evenness of the glass are not high. In a laminating process, the hard film layer is matched with the glass. Compared with the dimming glass which uses two pieces of glass, the dimming glass of the invention decreases the technological operation difficulty. Furthermore, the dimming glass provided by the invention has small change on the thickness of the glass and can be used together with universal glass. When the dimming glass is applied to the window of an automobile, the dimming glass has the advantages of basically ignored change of a vehicle door structure, no influence on lifting, good stability, effective prevention of ultraviolet and long service life.

Owner:BYD CO LTD

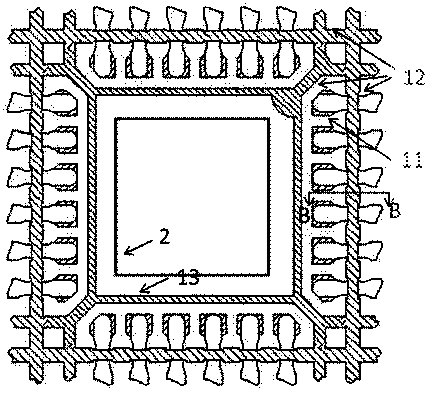

A packaging method of a QFN fingerprint identification chip

InactiveCN109037083ARaise pullIncrease impactSolid-state devicesSemiconductor/solid-state device manufacturingSilver pastePlastic packaging

The invention discloses a packaging method of a QFN fingerprint identification chip, belonging to the technical field of semiconductor chip packaging. The process comprises the following steps: mounting a loading film on the back of a lead frame; adhering the chip to the lead frame; curing silver paste; performing plasma cleaning; performing wire bonding; performing plastic packaging; removing theloading film; performing post curing; removing residual glue; baking; thinning a plastic cover and pasting a reinforcing film; cutting off a connecting rib to carry out a strip test; printing a marking; removing the reinforcing film; and cutting for molding. The invention provides a packaging method capable of improving the yield of QFN fingerprint identification chip packaging.

Owner:星科金朋半导体(江阴)有限公司

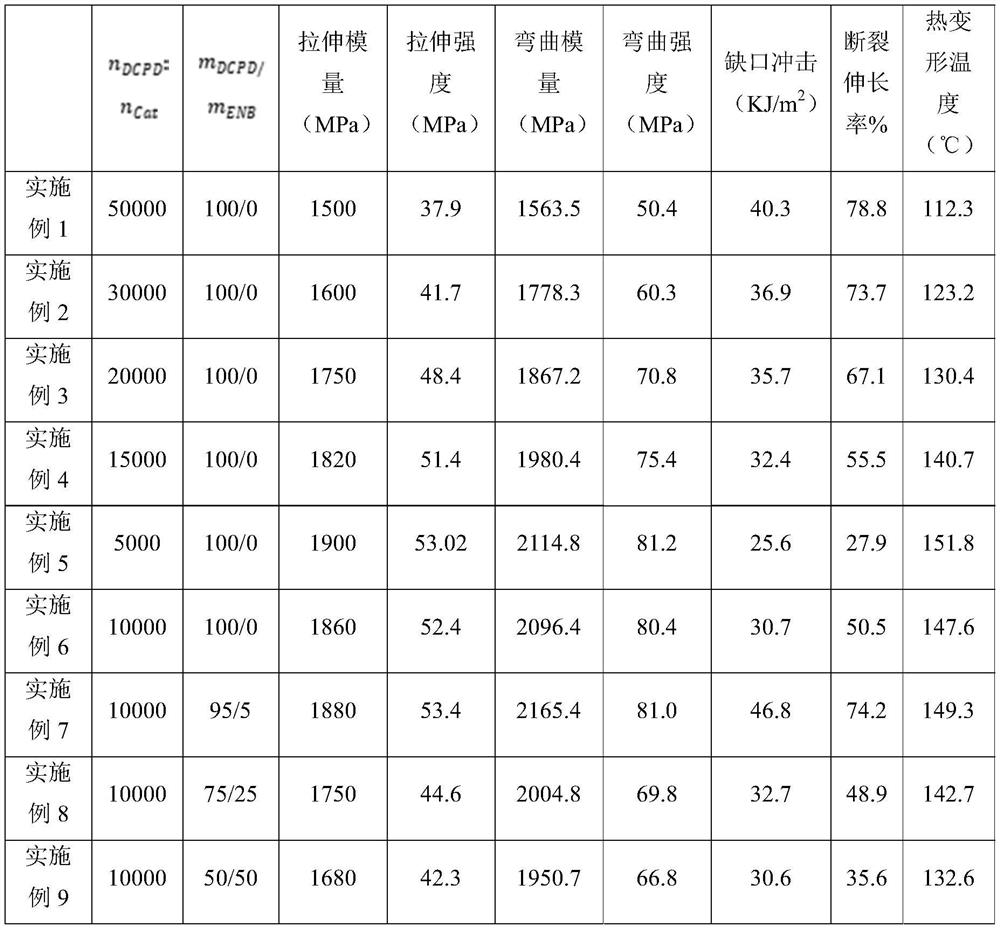

Dicyclopentadiene-ethylidene norbornene copolymer and preparation method thereof

The invention relates to the field of high polymer materials, in particular to a dicyclopentadiene-ethylidene norbornene copolymer and a preparation method thereof. The dicyclopentadiene-ethylidene norbornene copolymer comprises the following components in mass ratio: the mass ratio of a dicyclopentadiene monomer to a catalyst is (5000-50000): 1, the mass ratio of the dicyclopentadiene monomer to ethylidene norbornene is 100: (5-50), and the mass ratio of the dicyclopentadiene monomer to an antioxidant is 100: (0.01-2). The preparation method comprises the following steps of: fully and uniformly mixing an organic solvent in which dicyclopentadiene, ethylidene norbornene and the antioxidant are uniformly dissolved and an organic solvent in which the catalyst is uniformly dissolved, immediately injecting the mixture into a mold, carrying out curing molding at 40-80 DEG C, and carrying out post-treatment at 120-150 DEG C. The dicyclopentadiene-ethylidene norbornene copolymer disclosed by the invention has the advantages that the types of formula raw materials of the dicyclopentadiene-ethylidene norbornene copolymer are simplified, the ratio of the formula raw materials is adjusted, the dosage of the catalyst is reduced, the preparation process is simplified, and the copolymer with good strength, impact toughness and thermal stability is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

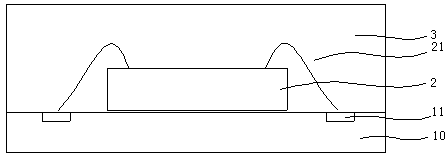

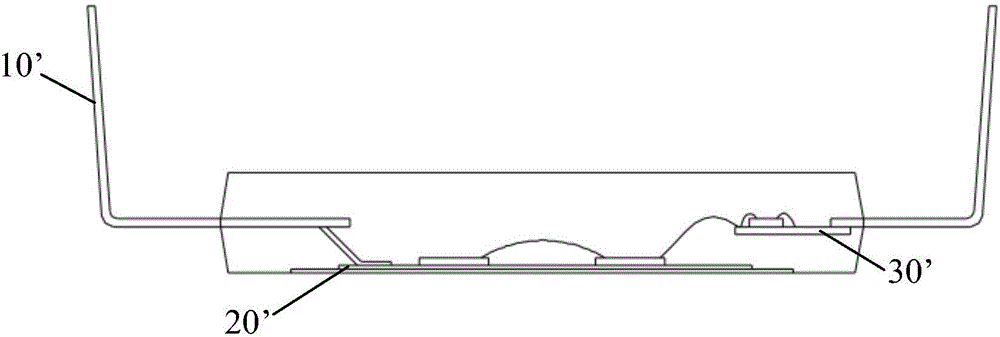

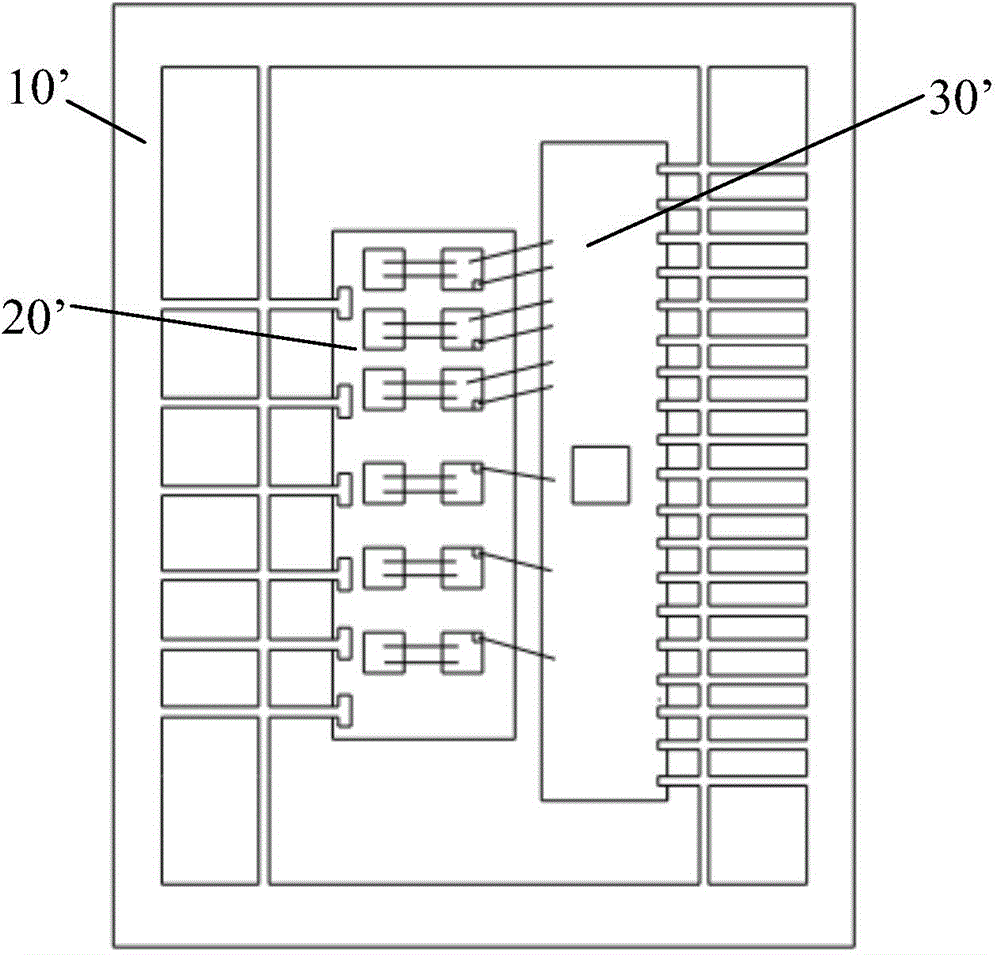

Plastic packaging type IPM module installing structure

InactiveCN104882428AReduces the risk of open or misplaced solder jointsReduce the difficulty of process operationSemiconductor/solid-state device detailsSolid-state devicesDislocationDBc

The invention discloses a plastic packaging type IPM module installing structure. The installing structure comprises a lead frame group. The installing structure further comprises a DBC plate and a PCB circuit board which are fixedly installed and electrically connected with the lead frame group. The DBC plate and the PCB circuit board are arranged in a mutually electrically connected way. A plurality of welding holes are arranged on the PCB circuit board. Welding pins corresponding to the welding holes are arranged on the lead frame group. The PCB circuit board and the lead frame group are welded and fixed through the welding holes and the welding pins. The risks of insufficient solder or welding dislocation due to simultaneous welding of multiple pins of the lead frame group can be lowered. The technical operation difficulties are alleviated. Product reliability is further improved.

Owner:XIAN YONGDIAN ELECTRIC

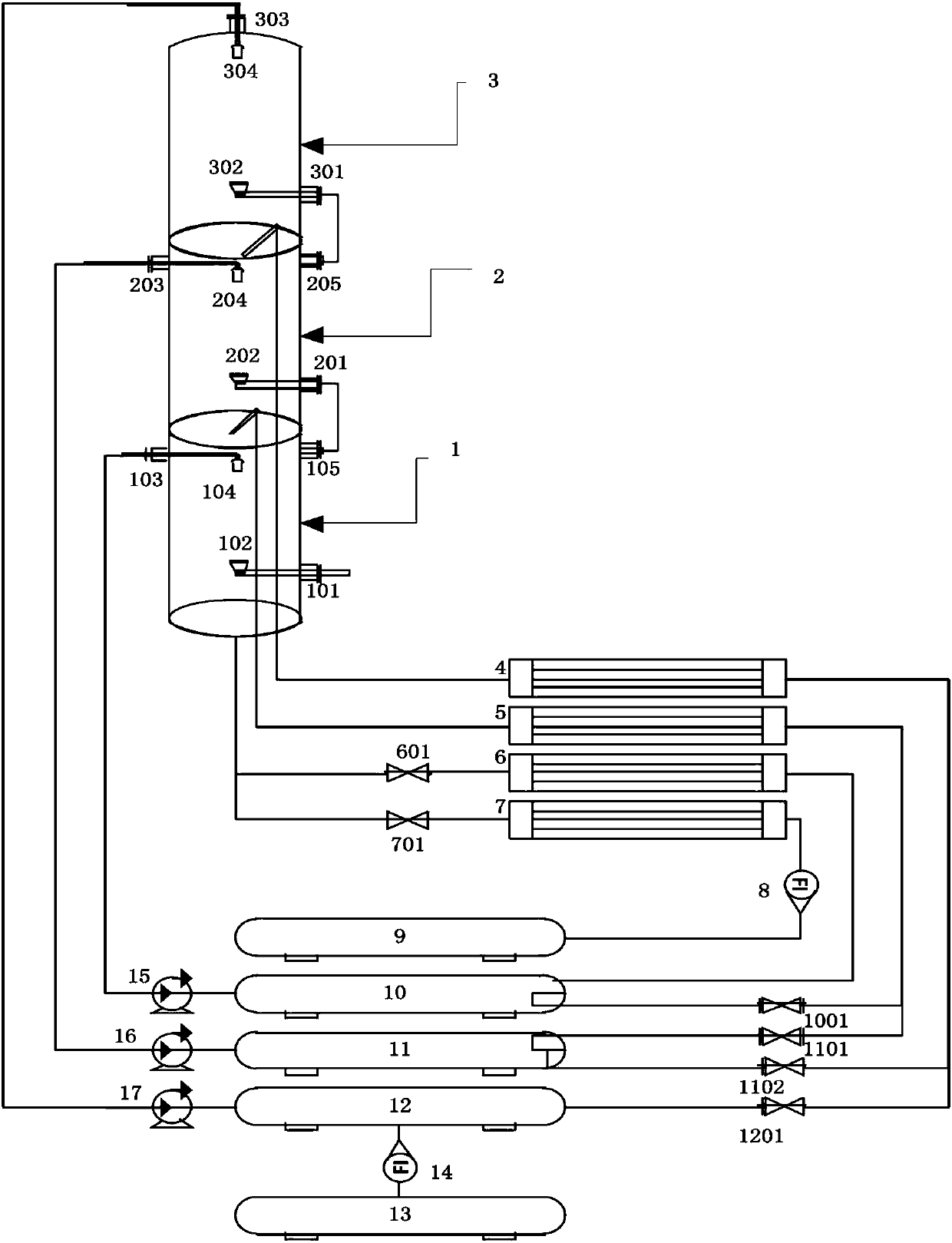

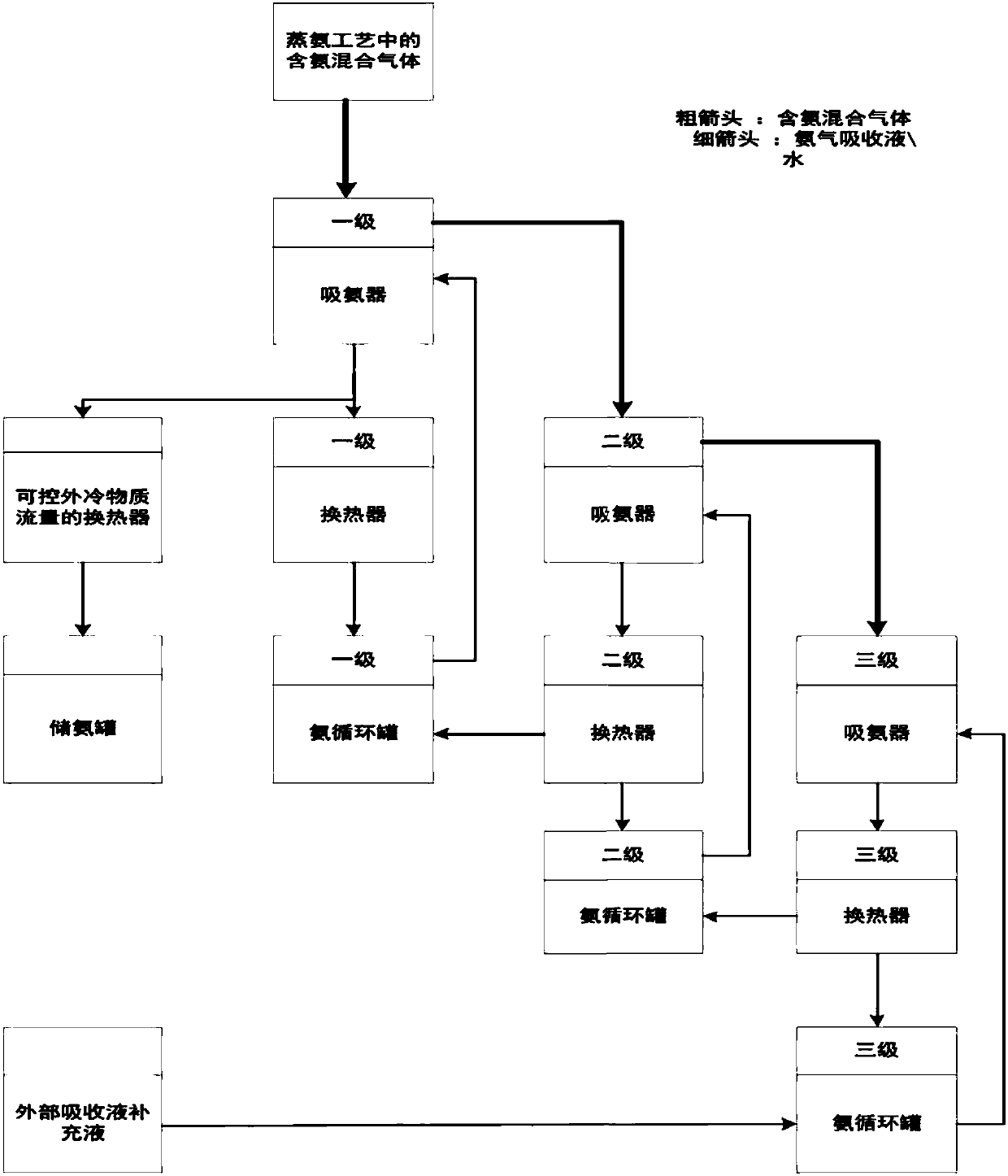

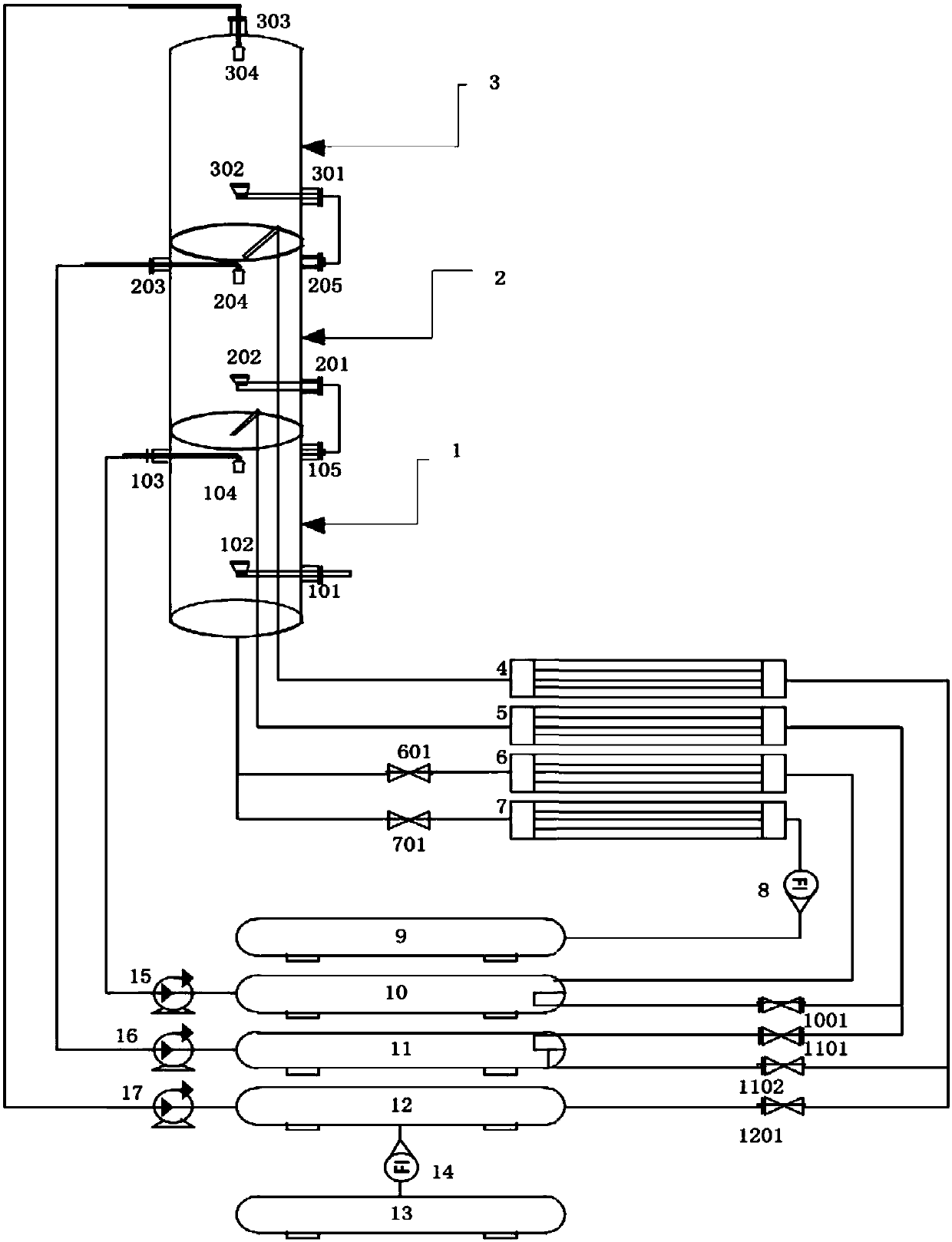

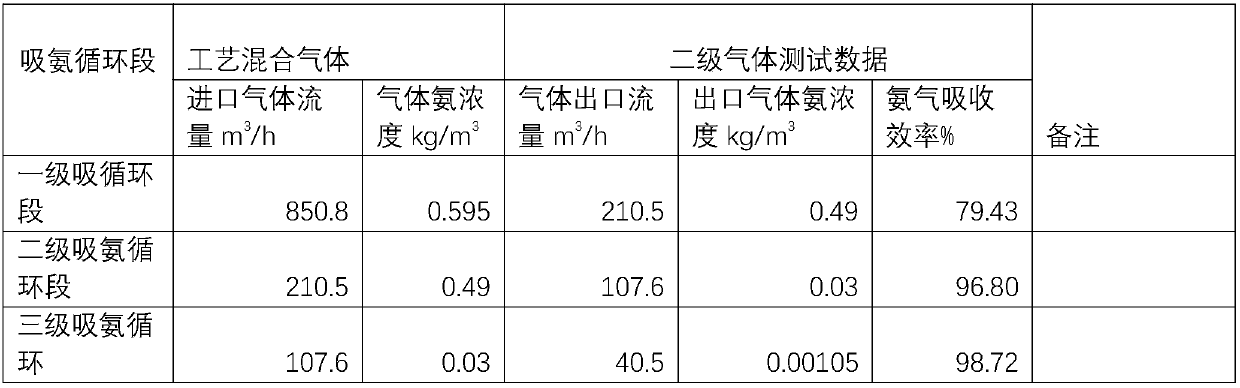

Ammonia absorption device

PendingCN107601552ARealize graded countercurrent absorptionImprove absorption rateZinc oxides/hydroxidesChemical industryAmmonia storageTower

The invention discloses an ammonia absorption device, comprising a multi-stage ammonia absorption tower, a heat exchanger, ammonia absorption circulating tanks, a process water pump and an ammonia storage tank, which form a closed circulating system through a process pipeline. The multi-stage ammonia absorption tower is composed of at least two stages of single ammonia absorption towers, wherein an ammonia outlet and an ammonia inlet of each single ammonia absorption tower are communicated with each other through a pipeline. Ammonia absorption liquid in each single ammonia absorption tower partially flows back into the corresponding ammonia absorption circulating tank for continuous circulating absorption, and partially flows back in the adjacent ammonia absorption circulating tank for replenishing absorption liquid, thereby implementing countercurrent circulating absorption of ammonia. The whole ammonia absorption device is at a continuous ammonia absorption circulating state, can automatically continuously discharge ammonia absorption recycling liquid with qualified concentration and high temperature, and has the characteristics of high ammonia absorption rate, simple operation and energy conservation and emission reduction.

Owner:SICHUAN JUHONG TECH

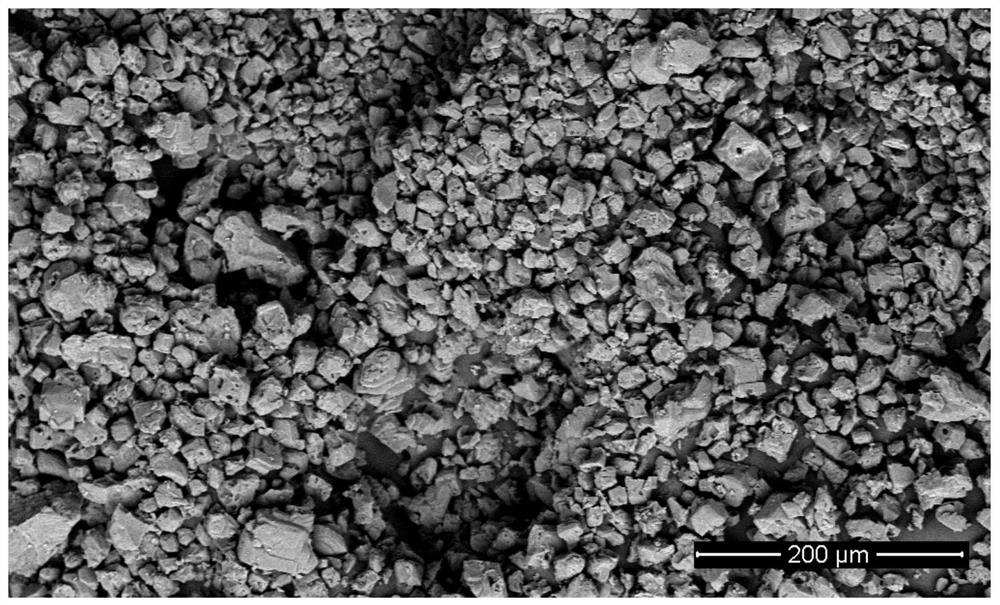

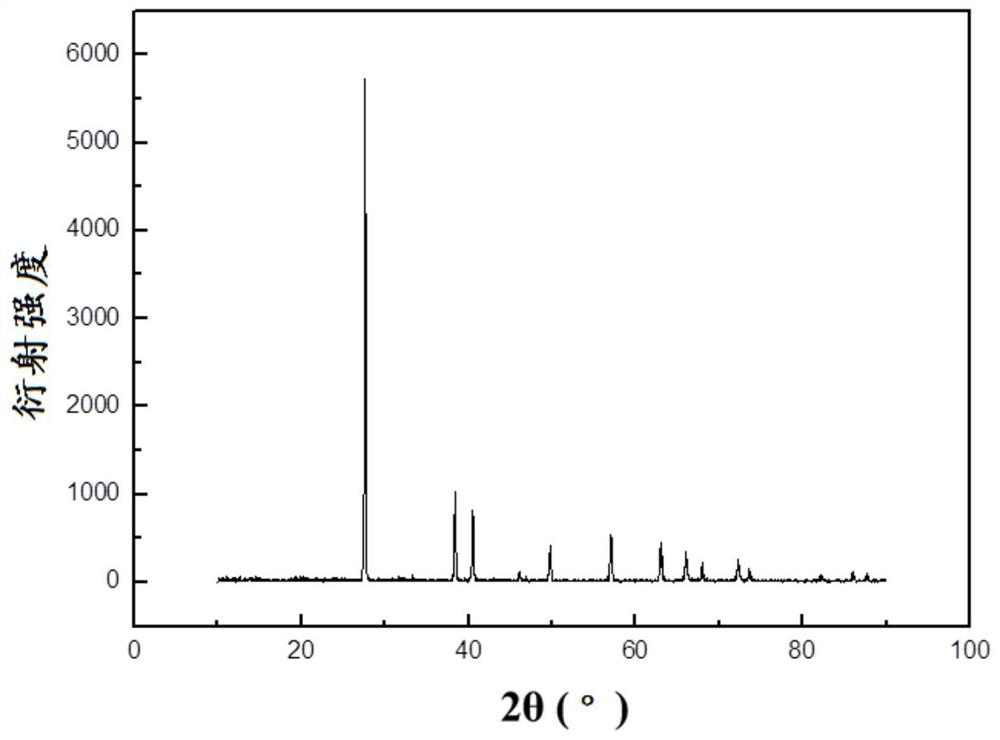

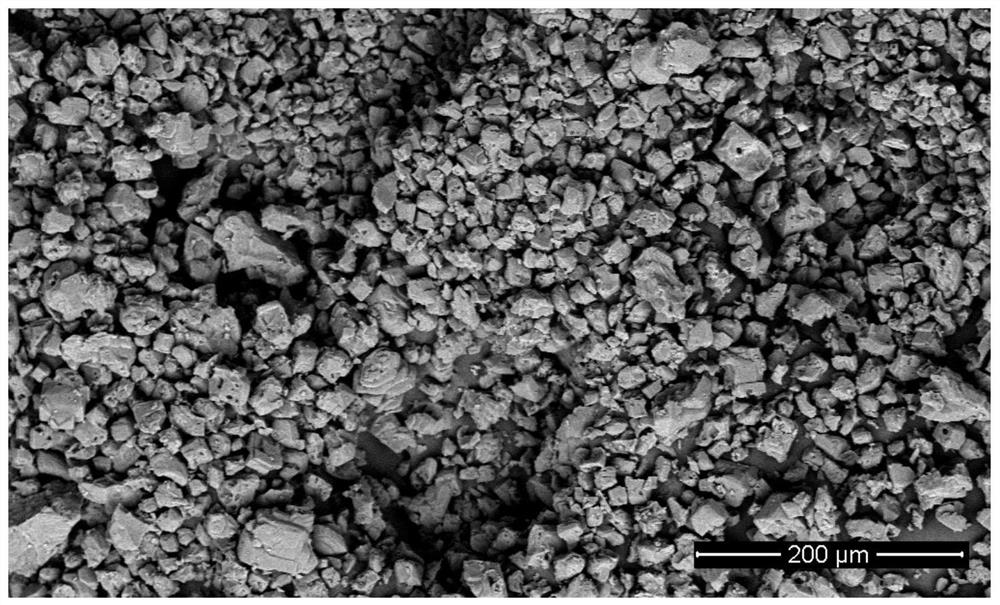

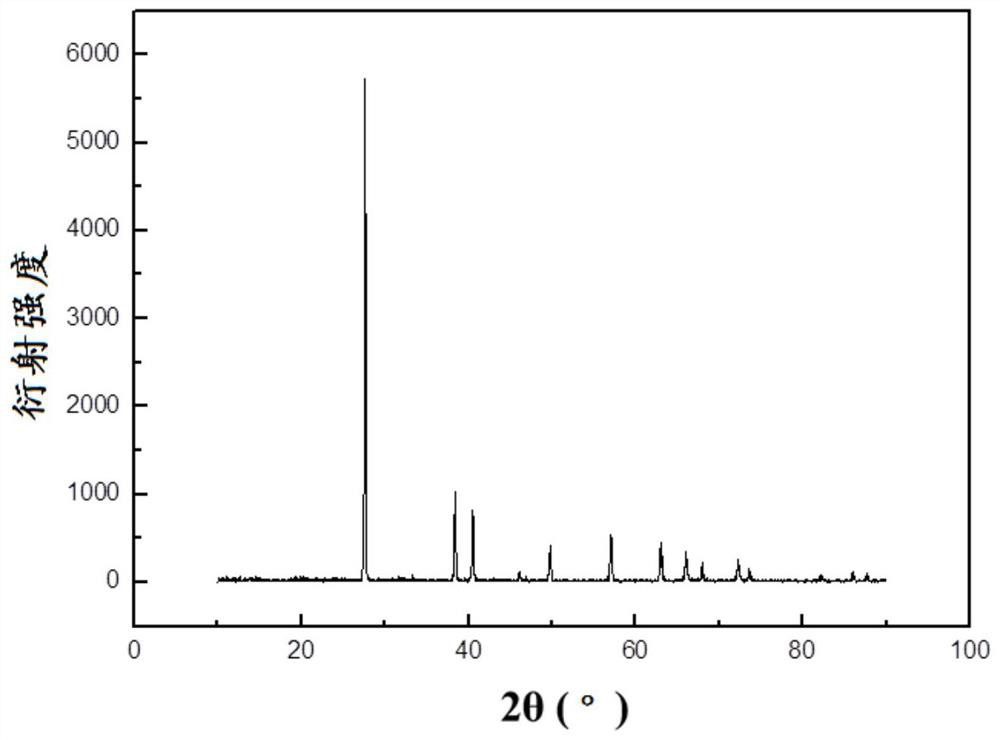

Synthesis method of alpha-aluminum trihydride

ActiveCN111994871AReduce equipment requirements and process operation difficultyHigh yieldMetal hydridesSide productCrystal transformation

The invention provides a synthesis method of alpha-aluminum trihydride, which comprises the following steps of: step 1, adding bis (bromomethyl) benzene into an anhydrous ether solution of lithium aluminum hydride, and reacting in an inert atmosphere to obtain an aluminum trihydride ether complex after the reaction is finished; and step 2, conveying the aluminum trihydride diethyl ether complex into toluene, carrying out deetherification precipitation, filtering, washing a filter cake, and drying the filter cake to obtain alpha-aluminum trihydride. According to the synthesis method, the used raw material bis (bromomethyl) benzene is easy to purify, the problems that the raw materials contain impurities such as FeCl3, are difficult to purify, are sensitive to moisture in air and the like are solved, a byproduct LiBr generated in the synthesis process is dissolved in a solvent diethyl ether, and an intermediate AlH3. N [(C2H5) 2O] solution in the synthesis process can be directly subjected to ether removal and crystal transformation in high-temperature toluene without filtration to generate alpha-AlH3, so that the equipment requirement and the process operation difficulty are reduced, and the obtained product is high in yield and good in quality.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

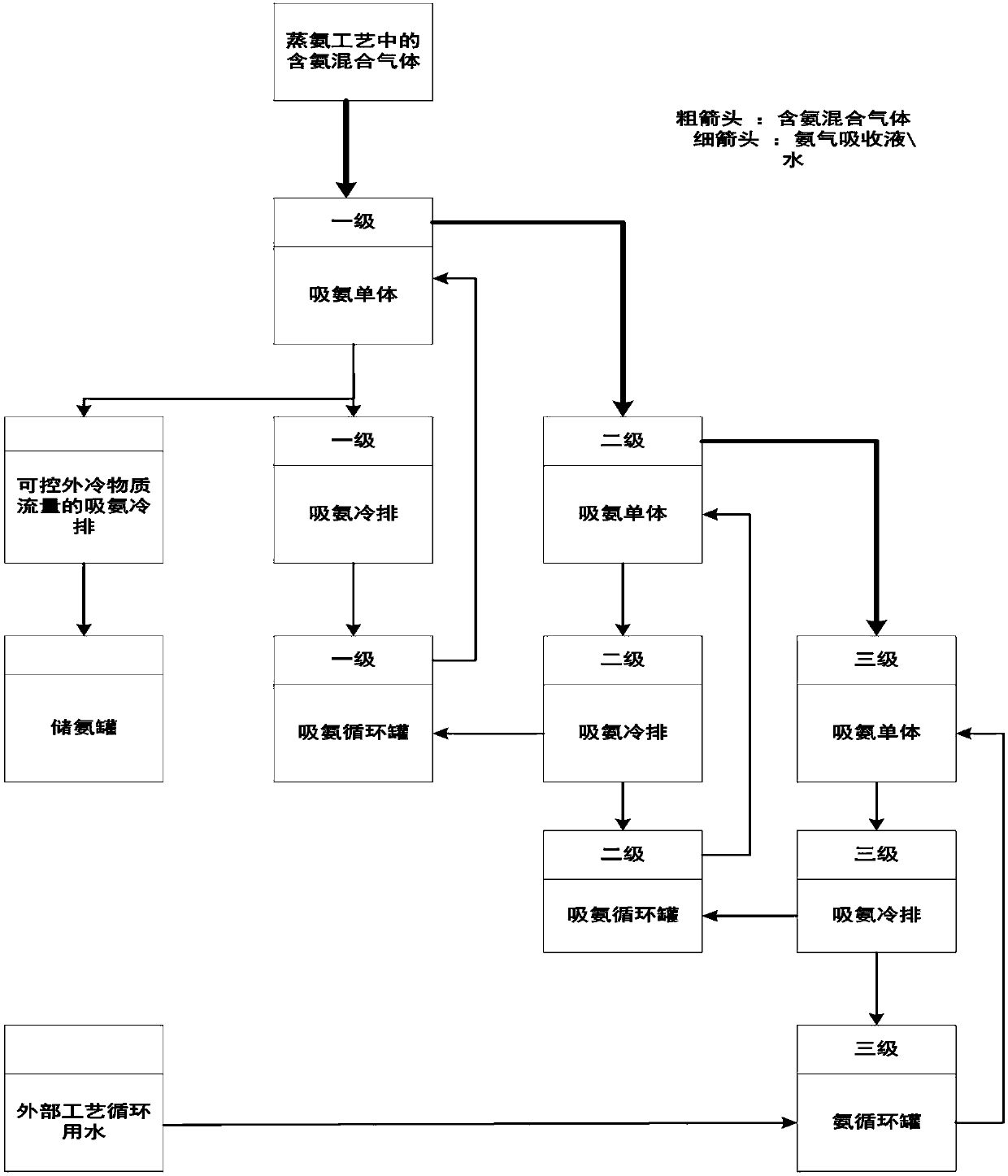

Multistage reverse cycle ammonia absorption process

ActiveCN107697931AImprove absorption rateRealize graded countercurrent circulation absorptionZinc oxides/hydroxidesChemical industryHigh concentrationAbsorption rate

The invention discloses a multistage reverse cycle ammonia absorption process which comprises multistage ammonia absorption cycle sections performed simultaneously. The process comprises the followingsteps: sequentially dividing each stage of the ammonia absorption cycle into 1, 2, ..., N stages of ammonia absorption cycles according to a higher concentration to a lower concentration of ammonia absorption liquid, enabling to-be-absorbed ammonia-containing mixed gas to sequentially flow through 1 to N stages of ammonia absorption cycle sections, absorbing ammonia absorption liquid with a highammonia-containing concentration, enabling incompletely absorbed gases to enter an adjacent lower stage ammonia absorption cycle section, and absorbing ammonia absorption liquid with a low ammonia-containing concentration; respectively enabling the ammonia absorption liquid in each stage of the ammonia absorption cycle to return to the local stage and the adjacent upper stage of the ammonia cycletanks so as to serve as replenishing liquor of the ammonia absorption liquid, wherein the N-stage ammonia absorption liquid is directly supplemented by external ammonia absorption liquid; and performing heat exchange treatment at controllable intensity on ammonia absorption liquid of which the ammonia-containing concentration reaches a specified value in the 1-stage ammonia absorption cycle section. Therefore, automatic continuous output of ammonia recycled liquid with a qualified concentration and a high temperature is realized. The multistage reverse cycle ammonia absorption process disclosed by the invention has the characteristics of being high in ammonia absorption rate, simple in operation, energy-saving and consumption-reducing.

Owner:SICHUAN JUHONG TECH

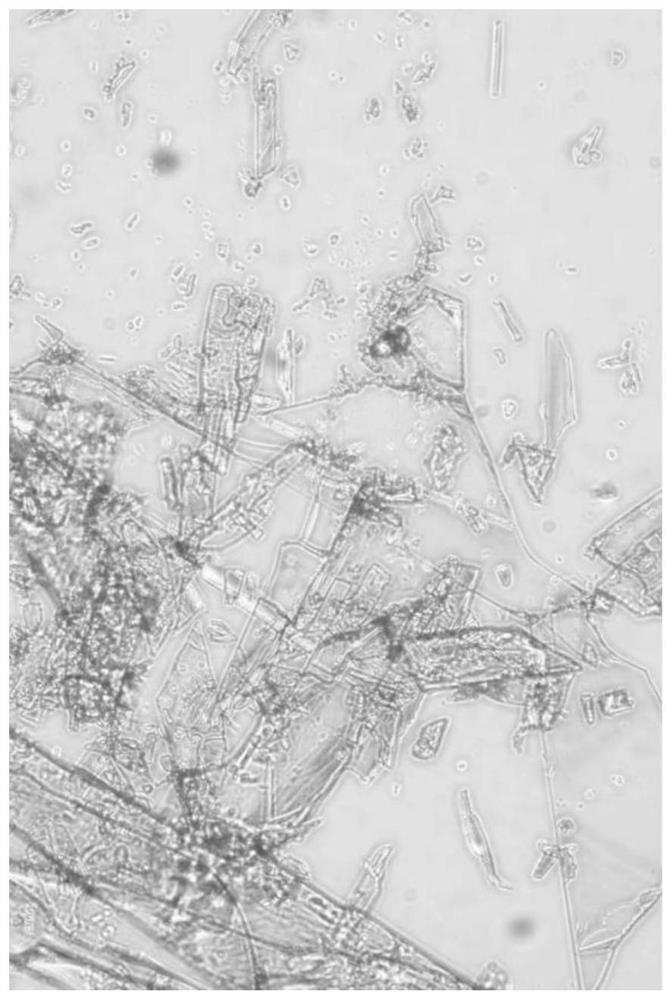

Method for preparing fisetin by enzyme method

PendingCN113754626AImprove solubilityReduce the difficulty of process operationOrganic chemistryHydrolysateFisetin

The invention discloses a method for preparing fisetin by an enzyme method. The method comprises the steps: crushing a raw material cotinus coggygria, and adding a citric acid solution and a plant extraction compound enzyme so as to enable the fisetin to be fully dissolved out of the citric acid solution; collecting enzymatic hydrolysate; concentrating the combined enzymatic hydrolysate into extract, adding high alcohol into the extract until the high alcohol is completely dissolved, and concentrating, crystallizing and drying filtrate to obtain a fisetin crude product; and recrystallizing the fisetin crude product twice by using a recrystallization solvent to obtain a high-purity fisetin refined product after twice recrystallization. According to the method, the citric acid solution is adopted to extract fisetin, so that fat-soluble substances in the enzymatic hydrolysate are extremely few, refining can be directly completed through a recrystallization process, a column chromatography process is not needed, the process operation difficulty and efficiency are reduced, the production efficiency is improved, and the method is suitable for industrial production. According to the invention, the recrystallization process is optimized, so that the refined fisetin product obtained after recrystallization is a needle-like crystal.

Owner:雅安职业技术学院

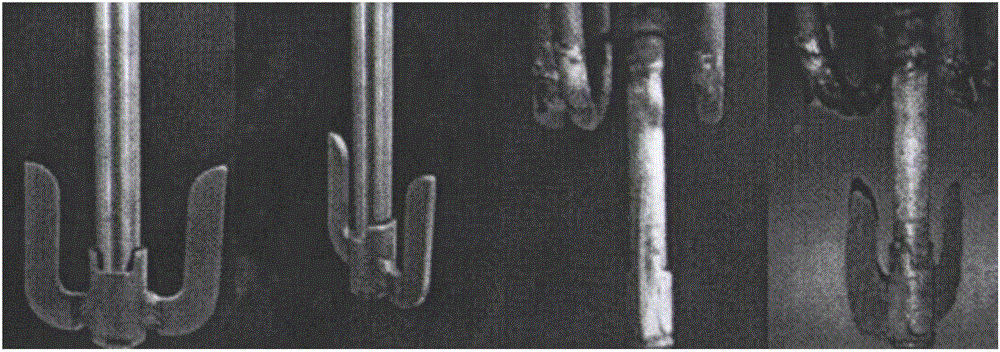

Storage battery provided with bipolar polar plate

InactiveCN102169997ANot easy to fall offStable charging and discharging performanceElectrode carriers/collectorsSecondary cellsRare earthEngineering

The invention discloses a storage battery provided with a bipolar polar plate, which comprises a polar plate base body and an active material loaded on the base body. The front surface and the back surface of the base body are respectively provided with crossed slant U-shaped grooves; the opening of the slant U-shaped groove on the front surface is slant upwards, and the groove is filled with a positive active material; the opening of the slant U-shaped groove on the back surface is slant downwards, and the groove is filled with a negative active material. Due to the pocket-shaped structure design, the positive active material is not easy to fall off in the charge-discharge process even in expansion so as to guarantee the stability of the polar plate charge-discharge performance. The base body is manufactured by casting alloy materials of lead-calcium-tin-aluminum, rare earth, and the like. Compared with the base body manufactured by the traditional titanium alloy casting technology, the production cost can be effectively reduced, the process operation difficulty can be reduced and the probability of generating air hole can be reduced, so that the product quality can be guaranteed.

Owner:张天任

Extraction method of purple sweet potato anthocyanin

The invention relates to the field of compound extraction and in particular relates to an extraction method of purple sweet potato anthocyanin. The extraction method is characterized by comprising thefollowing steps: a, adding a metal salt solution, 1-ethyl-3-methylimidazole acetate and 1-ethyl-3-methylimidazole diethyl phosphate into purple sweet potato slurry, and uniformly mixing; carrying outultrasonic and microwave cooperative treatment for 5 to 10 min; then carrying out microwave extraction for 5 to 15 min; carrying out de-coloring and clarificationimpurity removal on an extracting solution, and taking supernatant; concentrating and drying the supernatant to obtain extract; b, carrying out centrifugal separation on the extract and collecting filtrate; concentrating and drying the filtrate to obtain purple sweet potato anthocyanin extract. Compared with the prior art, the extraction method of the purple sweet potato anthocyanin has the advantages of simple technology and convenience for operation; the prepared anthocyanin has the characteristics of high extraction rate, high purity and the like and has very good popularization and application value.

Owner:UNIV OF JINAN

A method for efficient dehalogenation of waste plastics

ActiveCN105295088BPromote conversionIncrease the number ofPlastic recyclingHalogenReaction temperature

The invention discloses a method for efficiently dehalogenating waste plastics. The method comprises the following three steps: 1. quenching and tempering: adding an alkaline chemical raw material to the waste plastics, then adding a solution of a Ni<2+> chemical raw material / waste material and stirring and uniformly mixing the materials; 2. hydrothermal treatment: carrying out hydrothermal treatment on the prepared waste plastics at 200-240 DEG C for 10-60 minutes; 3. dehydration: carrying out solid-liquid separation on a mixture obtained after hydrothermal treatment, thus obtaining coke. The method has the beneficial effects that the function of Ni<2+> in plastic dehalogenation is confirmed for the first time; the method has the characteristics that the adding proportion of the alkaline chemical raw material is extremely small; the cost is low; the process is simple; the halogen removal efficiency is high; the reaction temperature is low; the time is short; the halogen containing rate of the waste plastics is reduced to about 0 from 56.8-74%; secondary pollution can not be caused; the plastics excluding halogen and some chemical raw materials after separation can be recycled, thus avoiding the problems of chlorine corrosion and dioxin pollution during halogen-containing plastic burning and providing beneficial conditions for harmless treatment and recycling of the halogen-containing plastics.

Owner:CHINA UNIV OF MINING & TECH

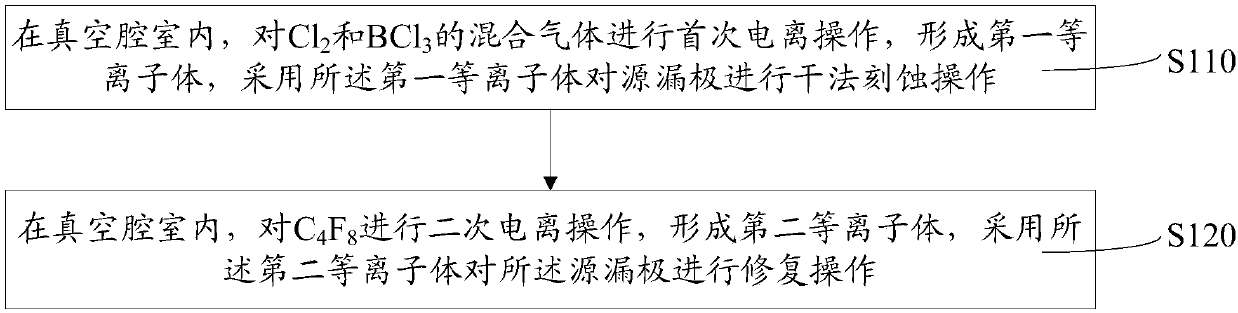

Etching method

InactiveCN107706105APromote absorptionReduce corrosionSemiconductor/solid-state device manufacturingEngineeringProcess engineering

An etching method comprises the steps of performing a first ionization operation on a mixed gas of Cl2 and BCl3 in a vacuum chamber to form a first plasma, and performing a dry etching operation on asource and a drain by using the first plasma; and performing a second ionization operation on C4F8 in the vacuum chamber to form a second plasma, and performing a repairing operation on the source anddrain by using the second plasma. In the above etching method, the main etching step and the repairing operation are performed in the same chamber without adding extra operating chamber or water washing device, so that the overall process operation is not difficult. Further, since C4F8 belongs to a compound with a relatively large molecular weight, the metal sidewall after the main etching can bewell protected during the repairing operation, and at the same time, the metal sidewall can be repaired and protected to some extent.

Owner:TRULY HUIZHOU SMART DISPLAY

A kind of synthetic method of α-aluminum hydride

ActiveCN111994871BLow equipment requirementsReduce the difficulty of process operationMetal hydridesBenzeneSolvent ether

The invention provides a synthetic method of α-aluminum trihydride, comprising: step 1, adding bis(bromomethyl)benzene into anhydrous ether solution of lithium aluminum hydride, reacting under an inert atmosphere, and obtaining three Aluminum hydride diethyl ether complex; step 2, transporting the aluminum trihydride diethyl ether complex to toluene for deether precipitation, filtering, washing the filter cake, and drying to obtain α-aluminum trihydride. Synthetic method of the present invention uses raw material two (bromomethyl) benzene easy purification, overcomes that raw material contains FeCl 3 other impurities and difficult to purify, sensitive to moisture in the air, etc., the by-product LiBr produced in the synthesis process is dissolved in the solvent ether, and the intermediate AlH in the synthesis process 3 n[(C 2 h 5 ) 2 O] solution can be deetherified directly in high temperature toluene without filtration to generate α‑AlH 3 , reducing the equipment requirements and process operation difficulty, and the obtained products have high yield and good quality.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

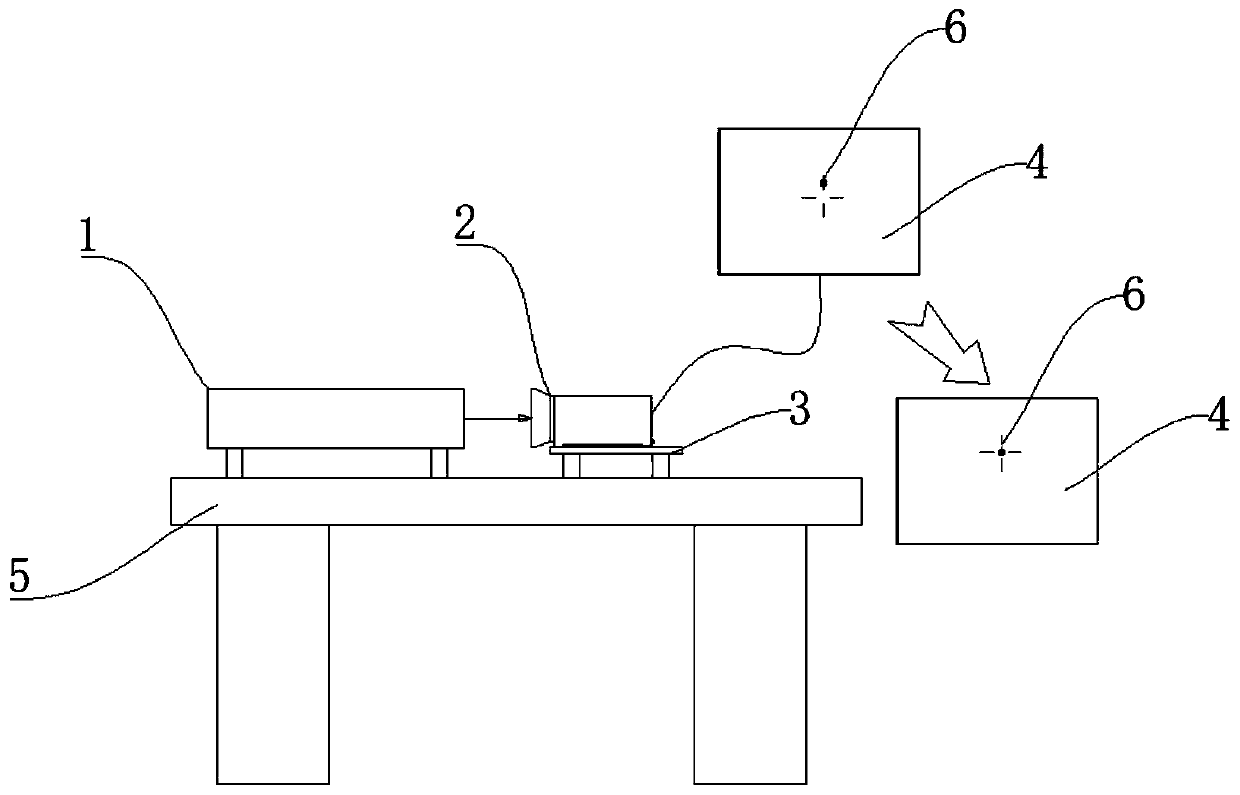

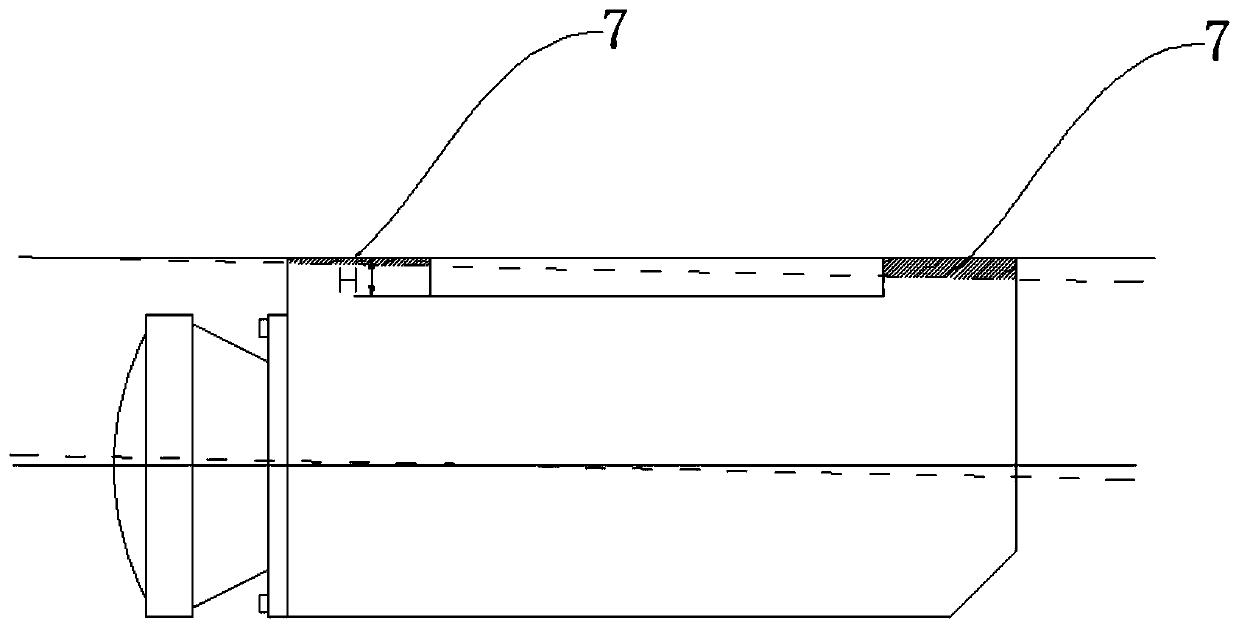

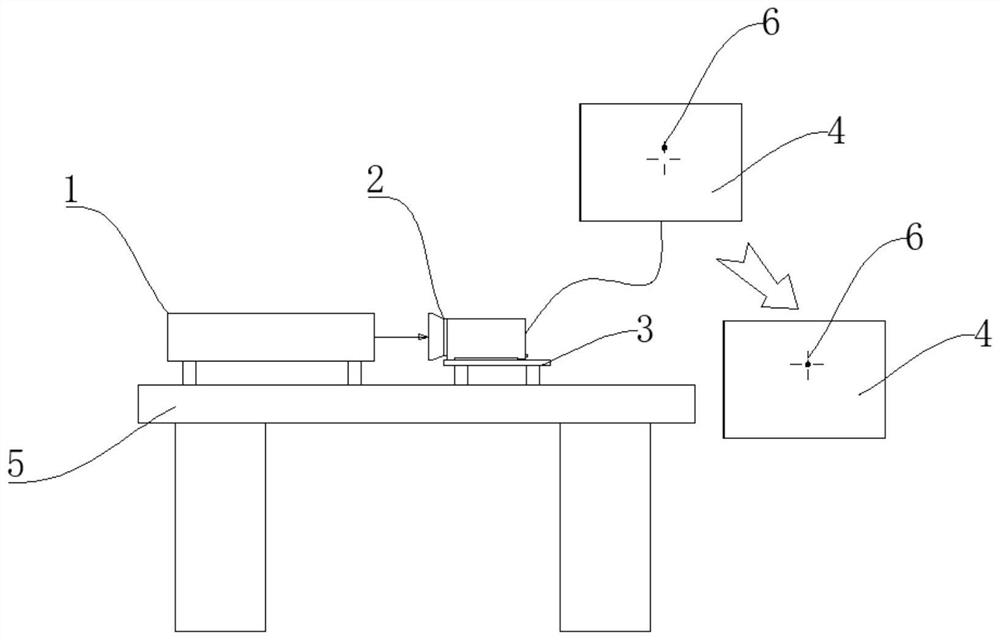

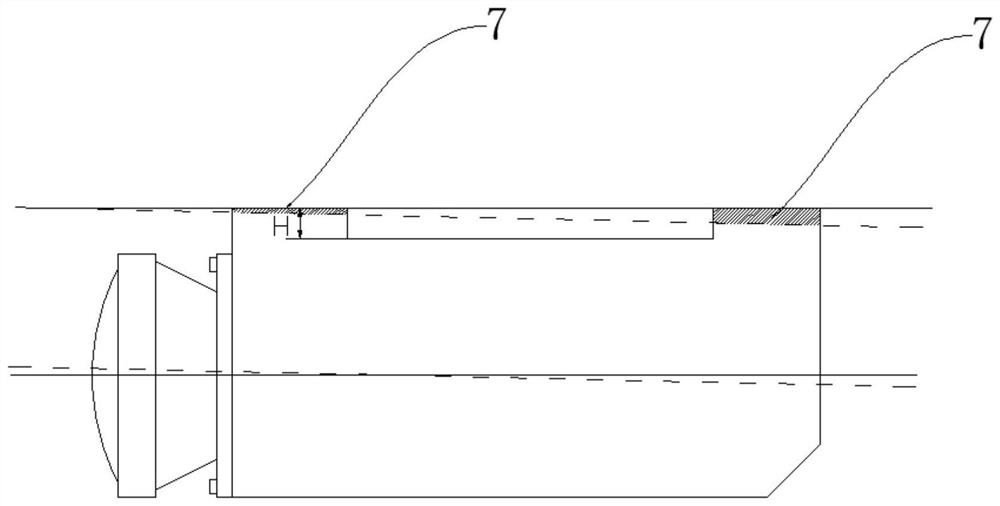

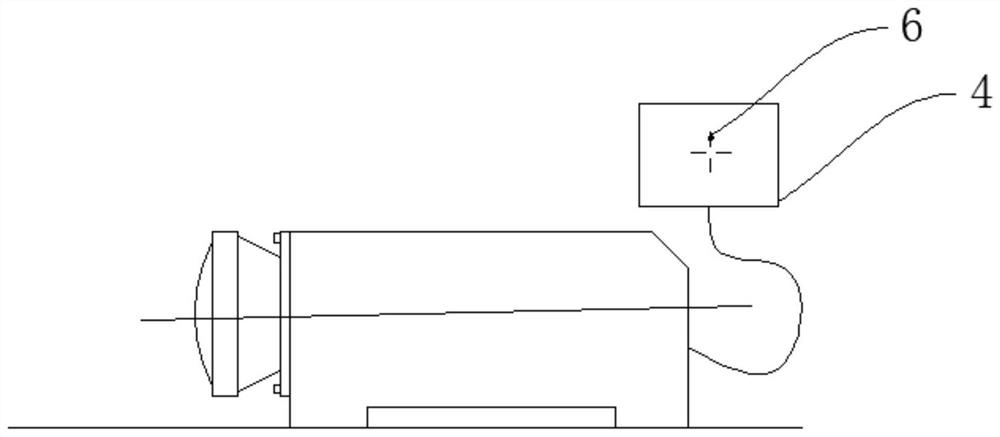

Thermal-imager installation reference surface deviation elimination installation and adjustment method

ActiveCN110440929AEliminate installation datum deviation in real timeHigh standardRadiation pyrometryEngineeringReference surface

The invention discloses a thermal-imager installation reference surface deviation elimination installation and adjustment method, and relates to a thermal-imager calibration and installation technology, and particularly to technology of thermal-imager installation reference surface deviation elimination. According to the method of the invention, a place between an objective lens seat and a main shell body is padded with a correspondingly sized gasket according to deviation distance and an upper / lower position of deviation of a small-view-field imaging point relative to a moving dividing line to achieve the purpose of installation and adjustment. The method of the invention can quickly and conveniently eliminate thermal-imager installation reference surface deviation in real time, reduces rework, and saves production costs.

Owner:KUNMING NORTH INFRARED TECH CO LTD

New galangin compound and its preparation method and application

ActiveCN110183404BHigh anticancer activityHigh purityOrganic active ingredientsOrganic chemistry methodsFluorescenceUltraviolet

The invention belongs to the technical field of medicine preparation, and specifically relates to a (3,5,7-trihydroxy-2-phenyl-8-[1'S-(2", 4", 5"-trimethoxy-phenyl)- Propyl]-chromogen-4-ketone) compound and its preparation method and application. (3,5,7-trihydroxy-2-phenyl-8-[1'S-(2",4",5"-trimethyl Oxygen-phenyl)-propyl]-chromogen-4-ketone) compound is yellow needle crystal, easily soluble in solvents such as methanol and chloroform, not easily soluble in water, showing yellow fluorescence under ultraviolet light, and showing yellow fluorescence in iodine Appears yellowish-brown under steam. In addition, the compound has good anticancer activity and can be used in anticancer therapeutic drugs.

Owner:董玉

Machine-made silk wadding quilt and preparation method thereof

Owner:NANTONG LOVER APPL

Method for Eliminating Deviation of Thermal Imager Installation Datum Plane

ActiveCN110440929BEliminate installation datum deviation in real timeHigh standardRadiation pyrometryEngineeringMicroscope objective

The invention relates to a method for eliminating the deviation of a thermal imager installation datum plane, and relates to a thermal imager calibration technology, in particular to a process technology for eliminating the deviation of a thermal imager installation datum plane. The method of the present invention is based on the deviation distance and the upper and lower positions of the imaging point of the small field of view relative to the deviation of the moving reticle line, and a gasket of a corresponding size is placed between the objective lens seat and the main housing to achieve the purpose of assembly and adjustment. The method of the invention can quickly, conveniently and real-time eliminate the deviation of the installation reference plane of the thermal imager, thereby reducing rework and saving production cost.

Owner:KUNMING NORTH INFRARED TECH CO LTD

Method for preparing diepoxide by one-pot method

ActiveCN110981836AReduce the difficulty of process operationLow costOrganic chemistryAqueous solutionCombinatorial chemistry

The invention discloses a method for preparing diepoxide by a one-pot method. The method comprises the following steps: S1, epoxidation reaction: adding dialkene into a reactor at a low temperature, slowly dropwise adding an m-chloroperoxybenzoic acid solution, and reacting to obtain a diepoxide crude product solution; and S2, separation and purification: adding a reducing agent aqueous solution into the diepoxide crude product solution, carrying out a reduction reaction, extracting to separate out an organic phase, carrying out a neutralization reaction, extracting to separate out an organicphase, washing with water, removing water, filtering, and carrying out reduced pressure distillation on filtrate to obtain the diepoxide. According to the invention, the traditional process of preparing a solvent through high vacuum distillation is prevented, an m-chloroperoxybenzoic acid solid raw material does not need to be separated, the diepoxide is obtained through the one-pot reaction of the dialkene and the m-chloroperoxybenzoic acid solution, the process operation difficulty is reduced, the safety is improved, the purity of the prepared diepoxide is 91% or above, the yield is 95% or above, and the large-scale industrial production is facilitated.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

PVC foam advertising board with a thickness of 3‑5mm

The invention discloses a 3-5mm-thick polyvinyl chloride foamed poster board, belonging to the technical field of polyvinyl chloride boards. The poster board solves the problems of high density, poor toughness and poor surface smoothness in the existing products. The poster board is prepared from the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride SG8 resin, 42-45 parts of light calcium carbonate, 20-30 parts of poster moldboard reclaimed material, 9-12 parts of foaming regulator 903, 2.4-3.2 parts of lead salt composite stabilizer, 0.5-0.6 part of internal lubricant ZB-60, 0.3-0.4 part of polyethylene wax, 0.2-0.3 part of AP, 0.4-0.5 part of plasticizer OA3, 1.1-1.4 parts of heat-release AC (azodicarbonamide) foaming agent, 0.7-1.0 part of heat-absorption Zhongkai c-2 foaming agent, 0.07 part of blue light whitener and 0.5-1 part of toughener ACM. The density of the polyvinyl chloride foamed poster board is 0.3-0.4 g / cm<3>, and the thickness is 3-5mm.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com