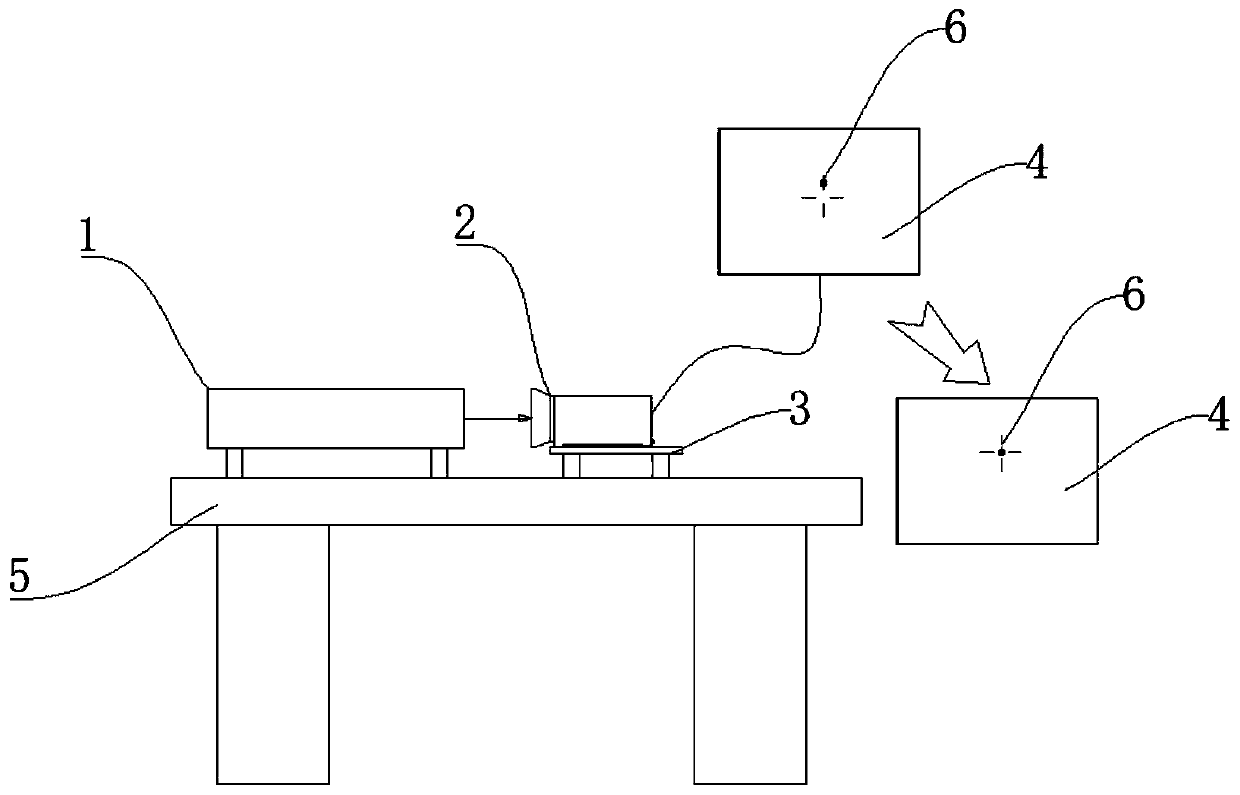

Thermal-imager installation reference surface deviation elimination installation and adjustment method

A technology for eliminating installation datum and deviation, which is applied in the technological field of eliminating the deviation of the installation datum plane of thermal imagers. The scrapping of parts, the elimination of installation datum deviation, and the effect of reducing the difficulty of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

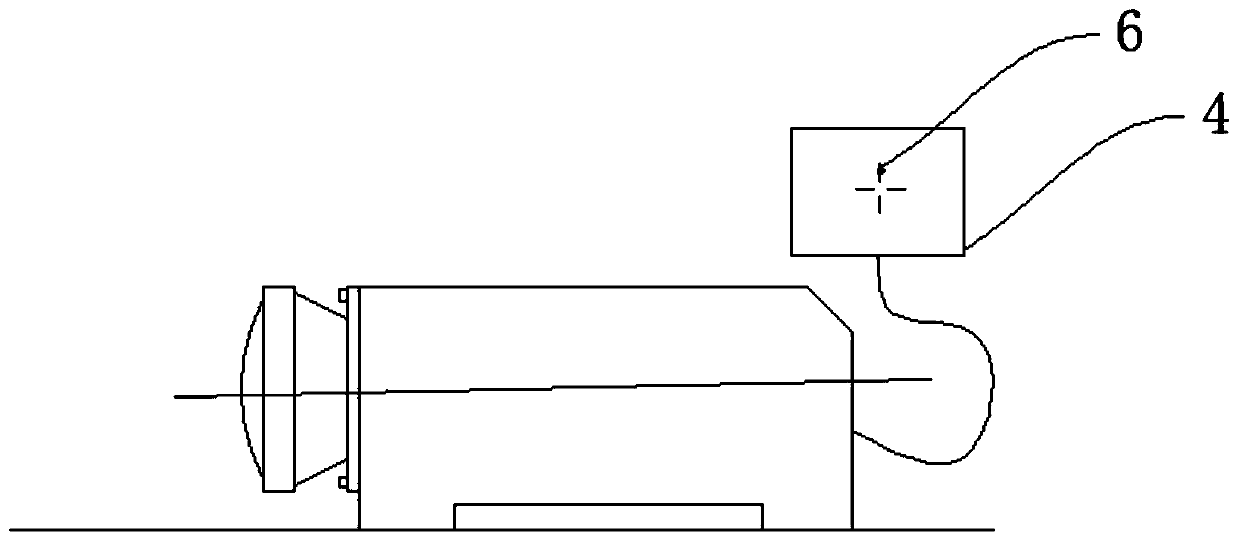

[0038] Example 1: When the type A product measures the deviation of the installation reference plane, the imaging point 6 of the small field of view deviates 34 steps upward from the center of the reticle, and the index is unqualified, such as image 3 As shown, it needs to be adjusted.

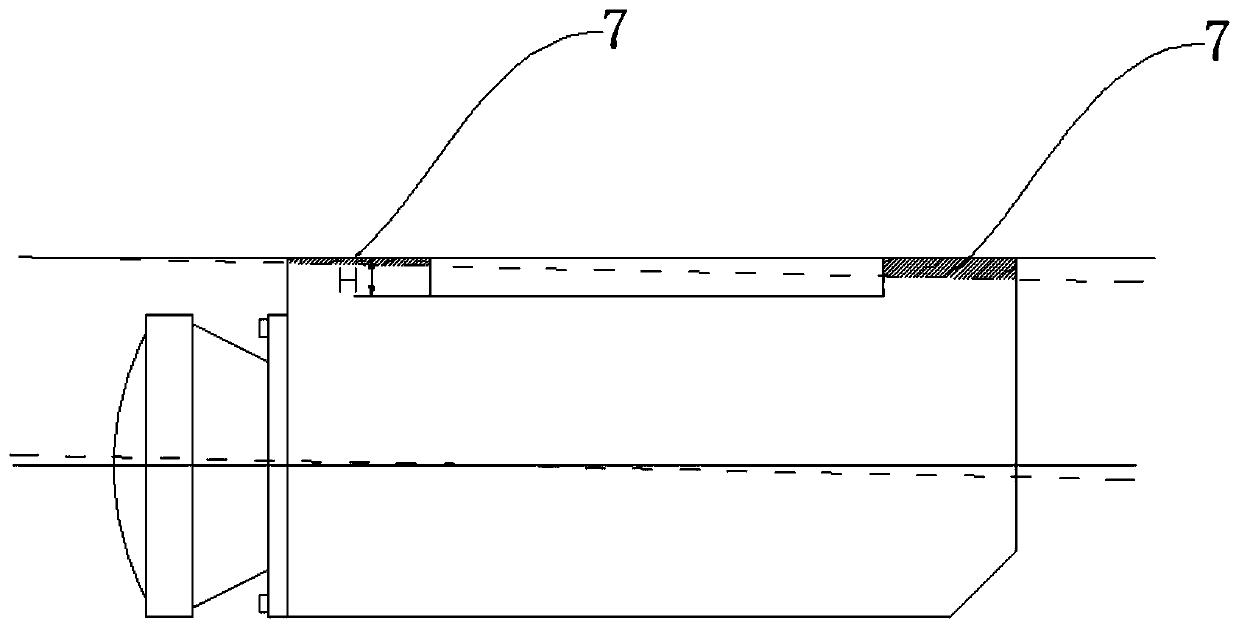

[0039] The small field of view imaging point 6 deviates upward relative to the moving reticle line. The gasket 8 is specifically installed between the objective lens holder and the main housing under the objective lens. Copper gaskets 8 are respectively placed under the two screws. Figure 4 shown. Refer to Table 1, step 34 is about to pad 0.25mm thick gasket 8. After the gasket is measured, the deviation index of the installation reference plane is 0.05mrad, which meets the index requirement of <0.5mrad, and the inspection is qualified.

Embodiment 2

[0040] Example 2: When the type B product measures the deviation of the installation reference plane, the imaging point 6 of the small field of view deviates 21 steps downward from the center of the reticle, and the index is unqualified, such as Figure 5 As shown, it needs to be adjusted.

[0041] The small field of view imaging point 6 deviates downward relative to the moving reticle line. The gasket 8 is specifically installed between the objective lens holder and the main housing on the objective lens. Copper gaskets are respectively placed on the two screws. Figure 6 shown. Look up Table 1, step 21 needs to pad about 0.15mm thick gasket 8. Measure the deviation of the installation datum plane in 3 steps after the copper sheet, that is, the deviation of the index is 0.15mrad, which meets the index of <0.5mrad, and the inspection is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com