Dimming glass and manufacturing method thereof

A technology of dimming glass and glass, which is applied in parallel glass structures, chemical instruments and methods, shading screens, etc., can solve problems such as difficult process operations, and achieve the effects of reducing process operation difficulty, good stability, and UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The embodiment 1 is used to make the dimming glass of the present invention.

[0036] (1) A polymer-dispersed liquid crystal layer is coated between two conductive layers, and then cured to produce a polymer-dispersed liquid crystal laminate. Coating conductive silver paste on one end surface of the two conductive layers, attaching two copper foils to the two conductive layers respectively, and connecting one lead wire from the copper foil. Wherein, the polymer-dispersed liquid crystal laminate is produced according to the method of Example 1 of CN101017304A, and the two conductive layers are polycarbonate with indium tin oxide conductive film on the surface.

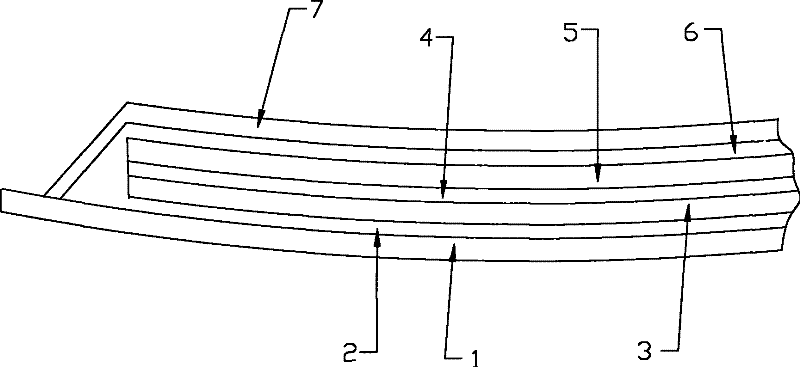

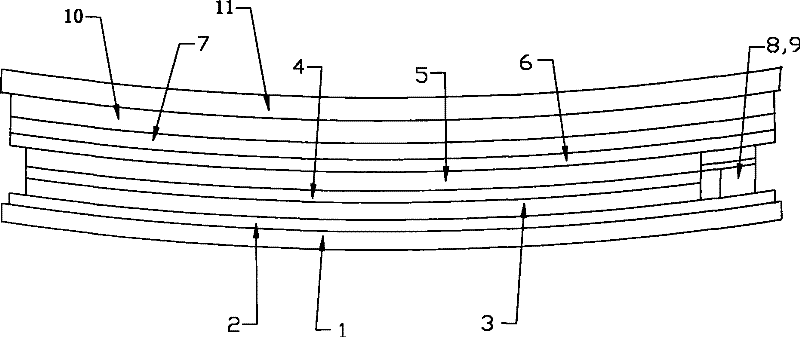

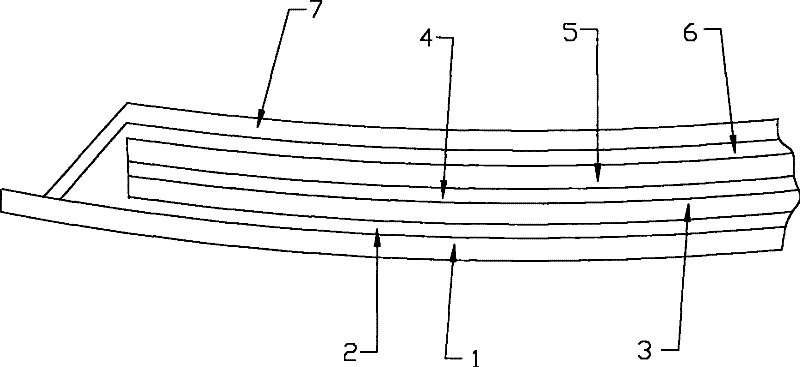

[0037] (2) Provide a piece of clean curved glass, cut a piece of adhesive layer (EVA) into the same size of curved glass 10, and place it on the bottom layer; the laminate obtained in step (1) is cut into the shape of curved glass, surrounded by Slightly smaller, keep the width of 1.0cm from the edge of the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com