Method for preparing fisetin by enzyme method

A technology of enzymatic preparation and fisetin, applied in organic chemistry and other directions, can solve problems such as poor bioavailability and stability, achieve good bioavailability and stability, avoid organic solvent reflux extraction, and high extraction rate of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

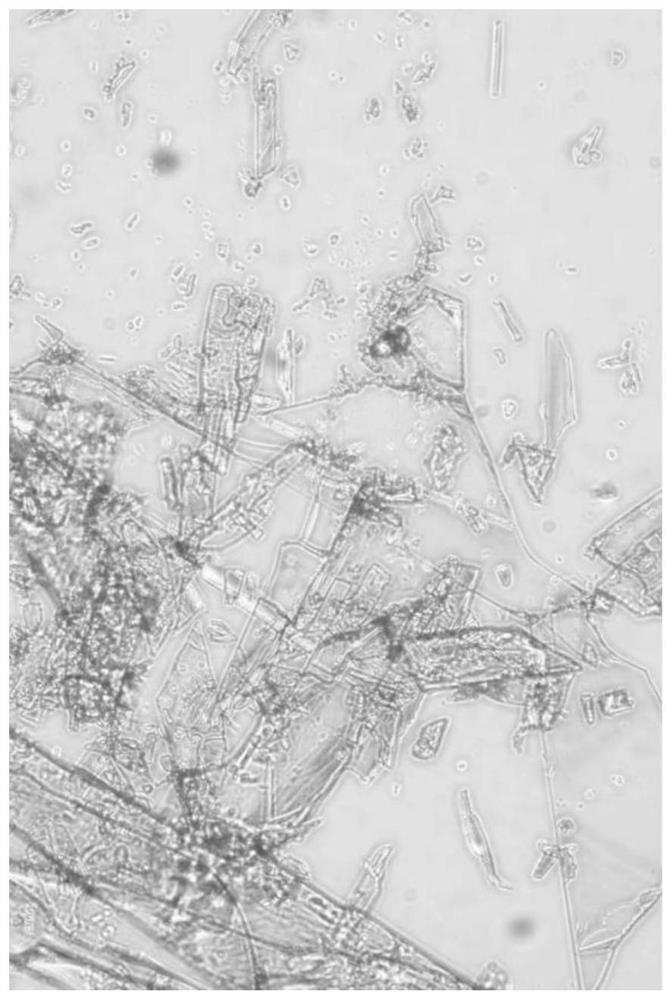

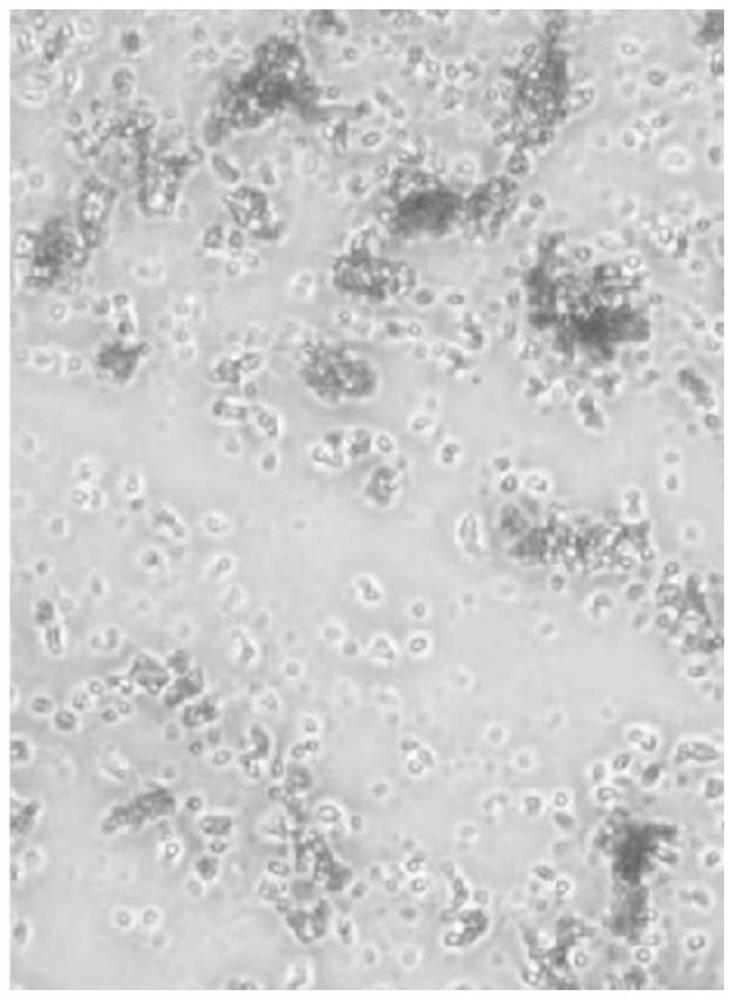

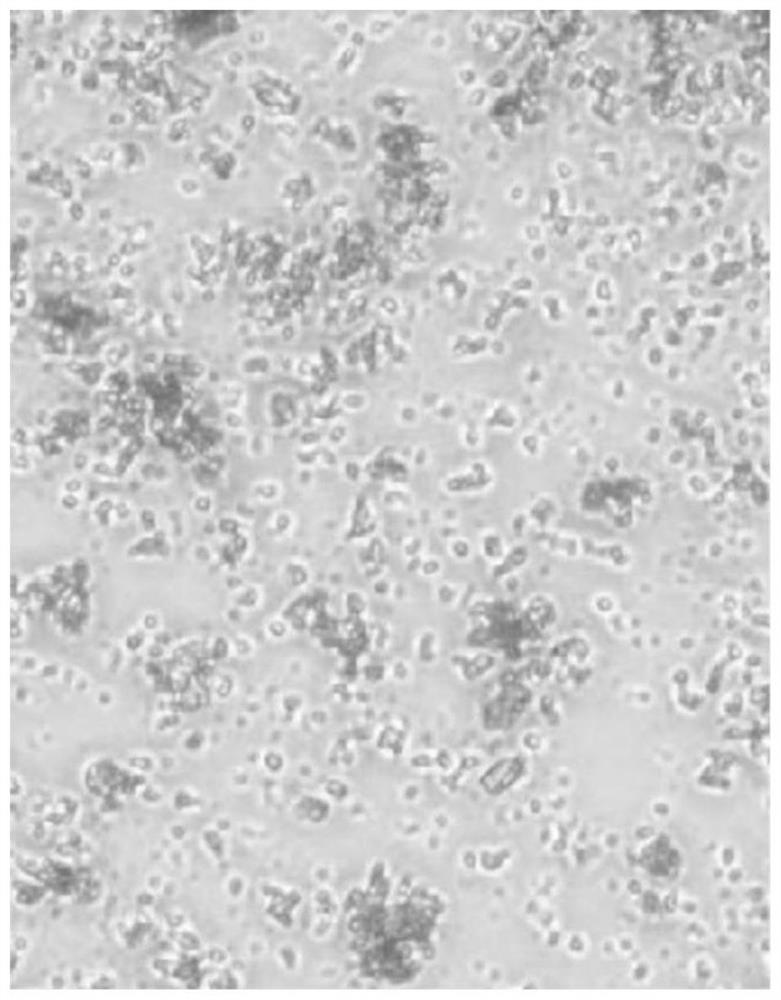

Image

Examples

Embodiment 1

[0061] A method for enzymatically preparing fisetin, comprising the following steps:

[0062] Step (1) enzymatic hydrolysis:

[0063] Grind the raw material sumac, take 200g raw material, add 2000ml citric acid solution, adjust the pH value to 5, add 2g plant extract complex enzyme, stir at 50°C for 4 hours, so that fisetin can be fully dissolved into the citric acid solution; Extract complex enzymes from living plants, collect the enzymatic solution; repeat the enzymatic extraction of raw materials, and combine the enzymatic solution to 3650ml;

[0064] Step (2) crude:

[0065] Concentrate the combined enzymolysis solution into 26.9g of extract, add 450ml of 95% methanol to the extract, heat until completely dissolved, then cool to room temperature and filter, the filtrate is concentrated, crystallized and dried to obtain 6.4g of crude fisetin ;

[0066] Step (3) recrystallization refinement:

[0067] 6.4g of crude fisetin was recrystallized twice using a recrystallizatio...

Embodiment 2

[0070] Grind the sumac raw material, weigh 200g raw material and put it into a three-neck flask, add 2000ml pH=5 citric acid solution, add 2.5g plant extract complex enzyme, stir at 50°C for 4 hours, add 5% NaoH solution to adjust pH=7 , collect the enzymolysis solution; repeat the above steps to combine the enzymolysis solution to a total of 3700ml.

[0071] 2) Concentrate the enzymatic solution in vacuum to obtain 31g of extract;

[0072] 3) Add 460ml of methanol with a purity of 99% to the extract, heat to dissolve completely, cool to room temperature, filter, concentrate, crystallize and dry the filtrate to obtain 6.1g of crude fisetin.

[0073] 4) Repeat the crystallization of 6.1g of crude fisetin twice twice to obtain 2.3g of fisetin. The first recrystallization uses 192ml of 1:1 acetone / ethanol mixture, and the second recrystallization uses 192ml of 98% methanol.

[0074] The HPLC detection normalization method content was 98.7%, and the external standard method conte...

Embodiment 3

[0076] Grind the raw material of sumac, weigh 50kg of raw material in the extraction tank, add 350kg of water, add citric acid solution to adjust pH = 5, add 500g of plant extraction complex enzyme, cycle at 50°C for 4 hours, heat to boiling and return for 1 hour , collect the enzymolysis solution; repeat the above steps to combine the enzymolysis solution to a total of 630L.

[0077] 2) Concentrate the enzymatic solution in vacuum to obtain 7kg of extract;

[0078] 3) Add 70kg of 95% ethanol to the extract, heat to dissolve completely, cool to room temperature, filter, concentrate, crystallize and dry the filtrate to obtain 1.3kg of crude fisetin.

[0079] 4) Recrystallize 1.3kg of crude fisetin twice to obtain 505g of fisetin. The first recrystallization uses 192ml of 98% acetone / 95% ethanol mixture of 1:1, and the second recrystallization uses 192ml of 98% methanol .

[0080] The content of HPLC was 98.1% by normalization method and 97.6% by external standard method; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com