Preparation method of composite lithium salt concentrated solution

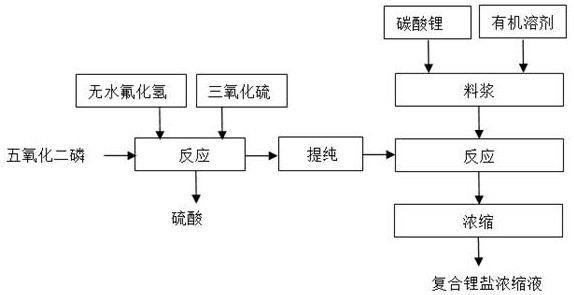

A technology of composite lithium salt and concentrated solution, which is applied in the field of preparation of composite lithium salt concentrated solution, can solve problems such as difficult product separation and purification, unfavorable industrialization implementation, poor thermal stability, etc., achieve short process production cycle, improve cycle performance and High-temperature storage performance and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example has prepared a kind of composite lithium salt concentrate, and concrete steps are as follows:

[0034] Replace the reaction vessel with nitrogen in advance, then add 69 g of phosphorus pentoxide, start stirring, and slowly add 97.2 g of anhydrous hydrofluoric acid and 155.5 g of sulfur trioxide gas at the same time, control the reaction temperature at 80°C, and the reaction time for 1 h. The produced gas was purified to obtain 120 g of phosphorus pentafluoride gas.

[0035] Under the protection of nitrogen, add 280 g of dimethyl carbonate and 35 g of lithium carbonate to a closed container equipped with mechanical stirring, thermometer, and condenser, start stirring, control the reaction temperature at 30°C, and continuously introduce purified Phosphorus pentafluoride gas, the gas flow rate is 0.35 L / min, continue to react for 3 h. After the reaction is finished, the reaction liquid is subjected to precision filtration, and then the filtrate is concentrate...

Embodiment 2

[0038] This example has prepared a kind of composite lithium salt concentrate, and concrete steps are as follows:

[0039] Replace the reaction vessel with argon in advance, then add 113 g of phosphorus pentoxide, start stirring, and slowly add 188.1 g of anhydrous hydrofluoric acid and 286.4 g of sulfur trioxide gas at the same time, control the reaction temperature at 120 °C, and the reaction time for 40 min. The resulting gas was purified to obtain 197.5 g of phosphorus pentafluoride gas.

[0040] Under the protection of argon, add 580 g of triethylene glycol dimethyl ether and 58 g of lithium carbonate into a closed container with mechanical stirring, thermometer, and condenser tube, start stirring, control the reaction temperature at 40 °C, and insert the gas tube through the bottom The phosphorus pentafluoride gas was continuously introduced at a gas flow rate of 0.44 L / min, and the reaction was continued for 2 h. After the reaction is finished, the reaction liquid is s...

Embodiment 3

[0043] This example has prepared a kind of composite lithium salt concentrate, and concrete steps are as follows:

[0044] Replace the reaction vessel with helium in advance, then add 162.2 g of phosphorus pentoxide, start stirring, and slowly add 339.2 g of anhydrous hydrofluoric acid and 456 g of sulfur trioxide gas at the same time, control the reaction temperature at 150 °C, and the reaction time for 0.5 h. The resulting gas was purified to obtain 285 g of phosphorus pentafluoride gas.

[0045]Under the protection of helium, add 860 g of acetone and 86 g of lithium carbonate to the airtight container equipped with mechanical stirring, thermometer, and condenser, start the stirring, control the reaction temperature at 50 °C, and continuously introduce pentafluoride Phosphorus gas, the gas flow rate was 0.65 L / min, and the reaction was continued for 1 h. After the reaction is finished, the reaction solution is subjected to precision filtration, and then the filtrate is conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com