Full-automatic wire tension control rewinding machine

A tension control and rewinding machine technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc. Equalization problem, to achieve the effect of reducing labor cost input, improving production efficiency, and high degree of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

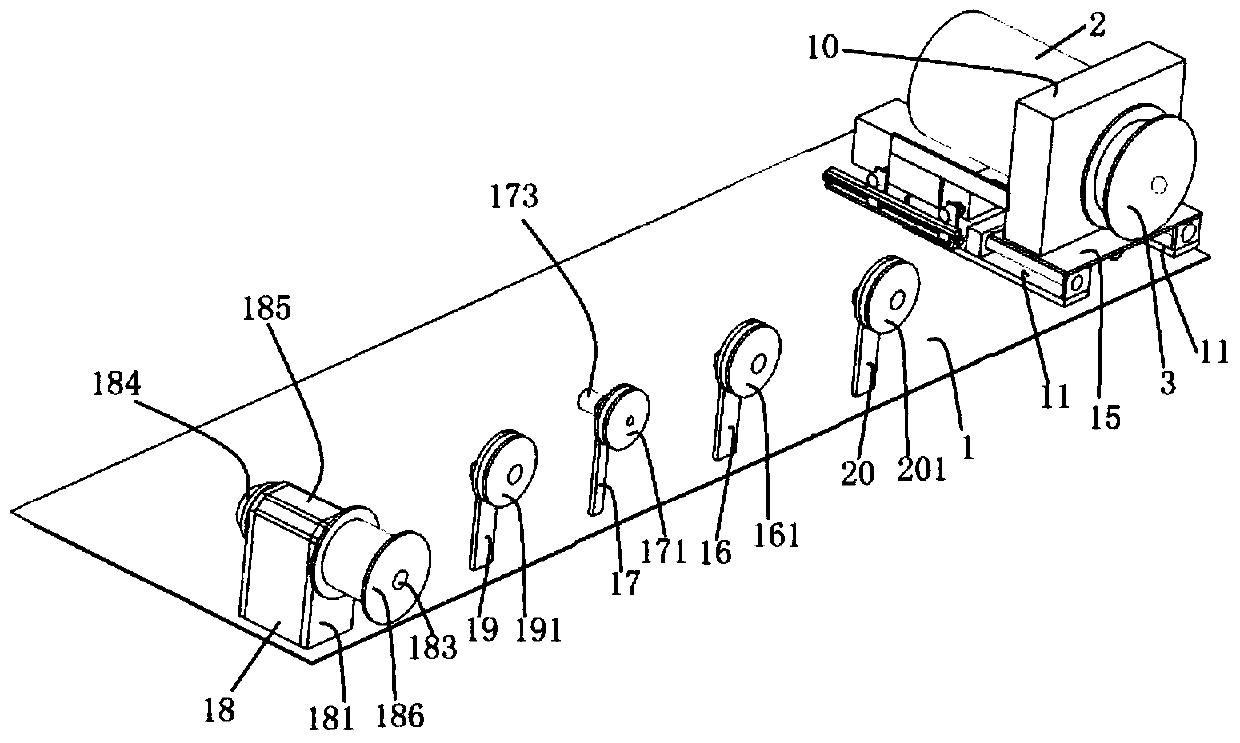

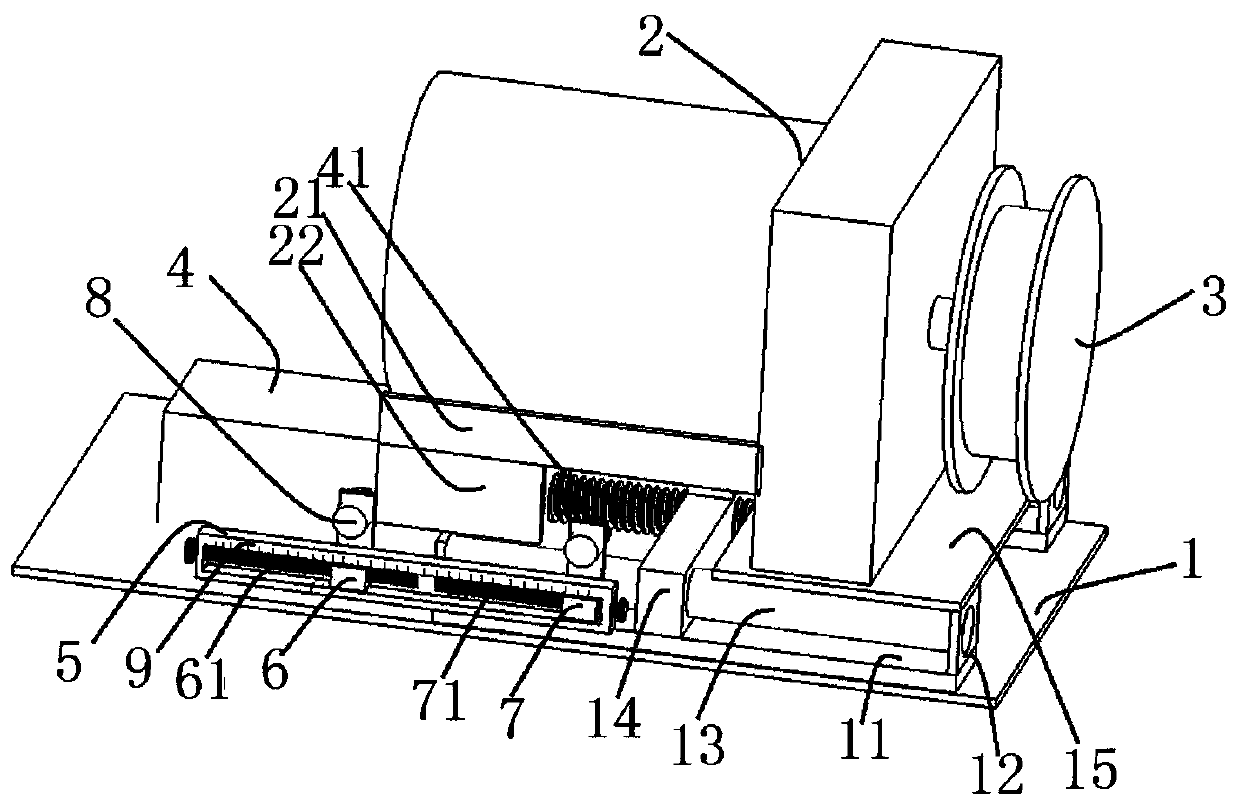

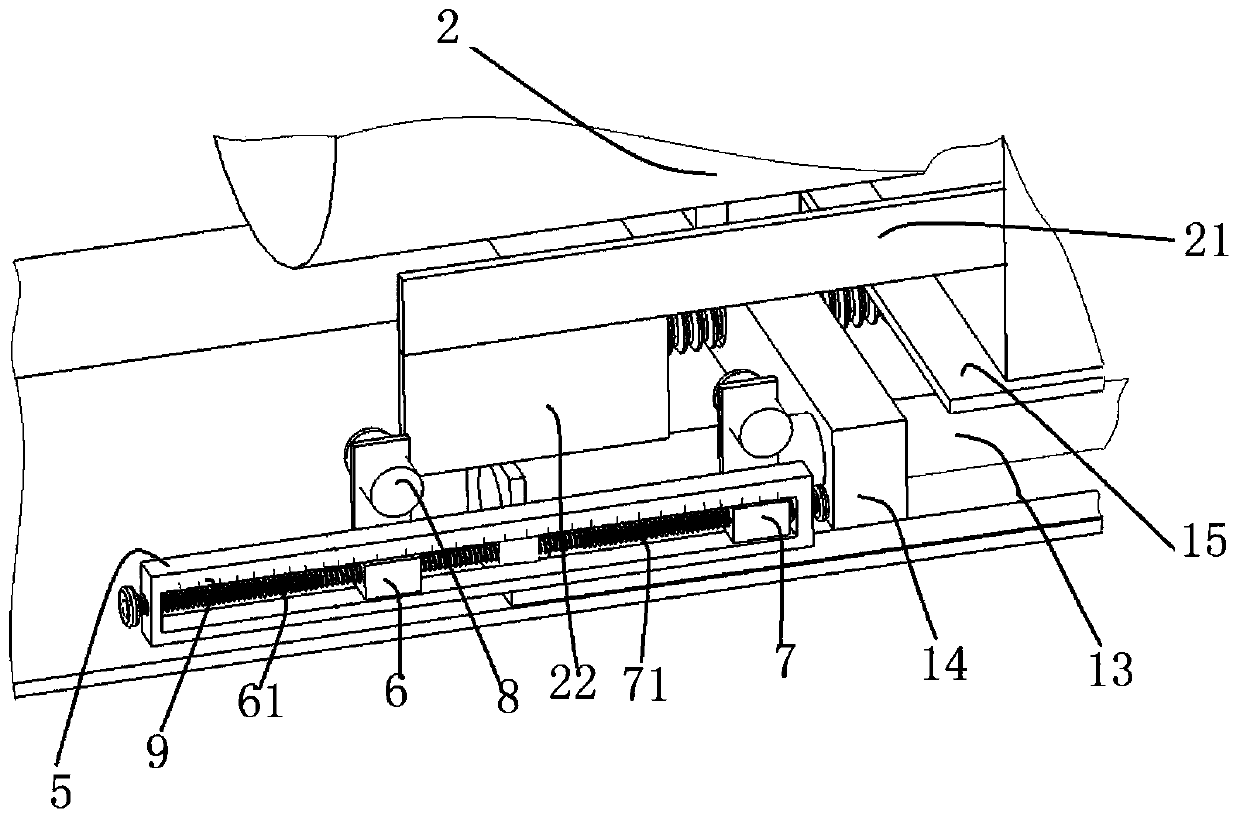

[0029] refer to Figure 1-6 , a fully automatic wire tension control rewinding machine, comprising a base plate 1, a wire pay-off device 18, a positioning mechanism 19, a tension sensor mechanism 17, a speed measuring mechanism 16, a wire positioning mechanism 20 and a wire take-up device 10, the base plate 1 On the top, a wire release device 18, a positioning mechanism 19, a tension sensor mechanism 17, a speed measuring mechanism 16, a wire positioning mechanism 20 and a wire take-up device 10 are arranged in sequence, and they are located on the same horizontal plane. 181, the material wire in the material wire reel 181 is wound around the positioning mechanism 19, the tension sensor mechanism 17, the speed measuring mechanism 16, and the wire positioning mechanism 20 in order to be placed in the wire take-up device 10; the wire take-up device 10 includes a motor 2, Winding reel 3, screw motor 4, scale frame 5, first sliding seat 6, first screw mandrel 61, second sliding se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com