Method for preparing diepoxide by one-pot method

A technology of diepoxide and epoxidation reaction, which is applied in the direction of organic chemistry, can solve the problems of poor process safety and low conversion rate of raw materials, and achieve the effects of reducing the difficulty of process operation, saving solvents and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

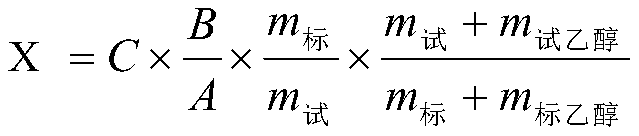

Image

Examples

Embodiment 1

[0078] A kind of one-pot method prepares the method for diepoxide, comprises the steps:

[0079] S1. Epoxidation reaction: Add 10.04g of 1,5-hexadiene into the reactor at low temperature, slowly add m-chloroperoxybenzoic acid solution dropwise, control the rate of addition to keep the system temperature at about 10°C, and maintain React at low temperature for 4 hours, then raise the temperature to 20°C, react for 15 hours, and the reaction is completed to obtain a crude solution of diepoxide, wherein the molar ratio of diene to m-chlorobenzoyl chloride is 1:2.45;

[0080] S2. Separation and purification: add 125 g of 20% sodium sulfite aqueous solution to the crude diepoxide solution, keep the system temperature at 20° C., perform a reduction reaction for 2 hours, extract and separate the organic phase. Add 165g of 20% sodium bicarbonate solution by mass fraction to the organic phase, maintain the system at 20°C, neutralize for 3 hours, and extract the organic phase. Wash the...

Embodiment 2

[0086] A kind of one-pot method prepares the method for diepoxide, comprises the steps:

[0087] S1. Epoxidation reaction: Add 12.69g of 1,7-octadiene into the reactor at low temperature, slowly add m-chloroperoxybenzoic acid solution dropwise, control the rate of addition to keep the system temperature at about 10°C, and maintain React at low temperature for 4 hours, then raise the temperature to 23°C, react for 12 hours, and the reaction is completed to obtain a crude product solution of diepoxyoctane, wherein the molar ratio of diene to m-chlorobenzoyl chloride is 1:2.6;

[0088] S2. Separation and purification: Add 220 g of a 20% mass fraction of sodium bisulfite aqueous solution to the crude diepoxyoctane solution, keep the system temperature at 23° C., perform a reduction reaction for 2 hours, and extract and separate the organic phase. Add 220 g of 20% sodium carbonate solution in mass fraction to the organic phase, maintain the system at 23° C., neutralize for 2 h, ext...

Embodiment 3

[0094] A kind of one-pot method prepares the method for diepoxide, comprises the steps:

[0095] S1. Epoxidation reaction: Add 14.88g of 1,8-nonadiene into the reactor at low temperature, slowly add m-chloroperoxybenzoic acid solution dropwise, control the rate of addition to keep the system temperature at about 5°C, and maintain React at low temperature for 4 hours, then raise the temperature to 25°C, react for 12 hours, and the reaction is completed to obtain a crude solution of diepoxynonane, wherein the molar ratio of diene to m-chlorobenzoyl chloride is 1:2.5;

[0096] S2. Separation and purification: Add 235 g of 20% potassium bisulfite aqueous solution to the crude diepoxynonane solution, keep the system temperature at 22° C., perform a reduction reaction for 1 hour, and extract and separate the organic phase. Add 240 g of 22% potassium bicarbonate solution in mass fraction to the organic phase, maintain the system at 25° C., neutralize for 2 h, extract and separate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com