Dicyclopentadiene-ethylidene norbornene copolymer and preparation method thereof

A technology of ethylidene norbornene and dicyclopentadiene is applied in the field of dicyclopentadiene-ethylidene norbornene copolymer and its preparation, and can solve the problems of complicated process, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

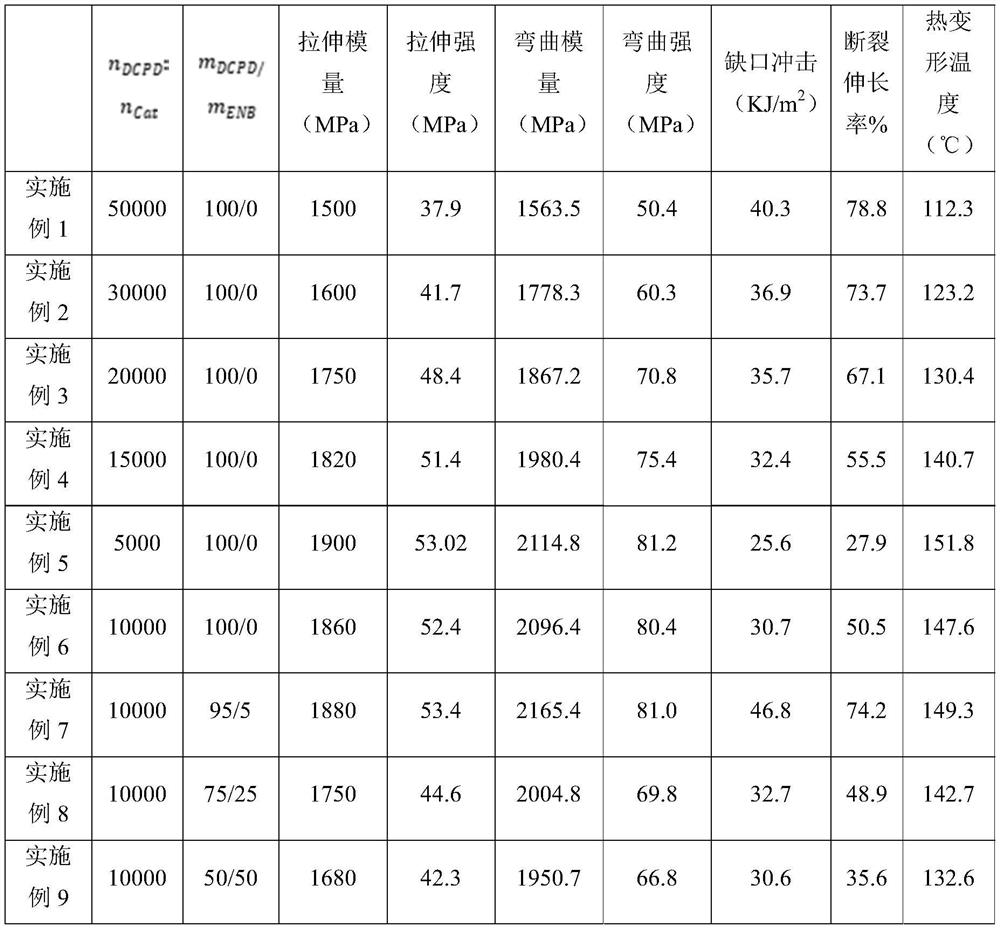

Examples

Embodiment 1

[0028] This example is used to illustrate the preparation method of dicyclopentadiene homopolymer when the amount ratio of dicyclopentadiene and catalyst substance in the present invention is 5000:1 (mass ratio is about 800:1)

[0029] (1) Configure catalyst solution A

[0030] Grubbs second-generation catalyst (424.5 mg, 0.5 mmol) was weighed in a glove box, and dissolved in 10.6 ml of dichloromethane to prepare a 40 mg / ml catalyst solution.

[0031] (2) configure dicyclopentadiene solution B

[0032] Add excess calcium hydride to dicyclopentadiene (purity greater than 95%), stir at 80°C for 12 hours under nitrogen protection, refine under reduced pressure, and then add dichloromethane solvent with 2%-5% dicyclopentadiene mass Fully dissolve in advance. Add dicyclopentadiene mass 0.01%-2% antioxidant (o-di-tert-butyl p-cresol) to the dicyclopentadiene solution under nitrogen protection, fully stir evenly on the low-temperature reaction bath, and control the temperature at 1...

Embodiment 2

[0038]This example is used to illustrate the preparation method of dicyclopentadiene homopolymer when the ratio of dicyclopentadiene and catalyst substance in the present invention is 10000:1 (mass ratio is about 1500:1)

[0039] (1) Configure catalyst solution A

[0040] Grubbs second-generation catalyst (424.5 mg, 0.5 mmol) was weighed in a glove box, and dissolved in 10.6 ml of dichloromethane to prepare a 40 mg / ml catalyst solution.

[0041] (2) configure dicyclopentadiene solution B

[0042] Add excess calcium hydride to dicyclopentadiene (purity greater than 95%), stir at 80°C for 12 hours under nitrogen protection, refine under reduced pressure, and then add dichloromethane solvent with 2%-5% dicyclopentadiene mass Fully dissolve in advance. Add 0.01%-2% antioxidant of dicyclopentadiene mass to the dicyclopentadiene solution under nitrogen protection, fully stir evenly on a low-temperature reaction bath, and control the temperature at 10-30°C.

[0043] (3) Hybrid cur...

Embodiment 3

[0048] This example is used to illustrate the preparation method of dicyclopentadiene homopolymer when the ratio of dicyclopentadiene and catalyst substance in the present invention is 15000:1 (mass ratio is about 2300:1)

[0049] (1) Configure catalyst solution A

[0050] Grubbs second-generation catalyst (424.5 mg, 0.5 mmol) was weighed in a glove box, and dissolved in 10.6 ml of dichloromethane to prepare a 40 mg / ml catalyst solution.

[0051] (2) configure dicyclopentadiene solution B

[0052] Add excess calcium hydride to dicyclopentadiene (purity greater than 95%), stir at 80°C for 12 hours under nitrogen protection, refine under reduced pressure, and then add dichloromethane solvent with 2%-5% dicyclopentadiene mass Fully dissolve in advance. Add 0.01%-2% antioxidant of dicyclopentadiene mass to the dicyclopentadiene solution under nitrogen protection, fully stir evenly on a low-temperature reaction bath, and control the temperature at 10-30°C.

[0053] (3) Hybrid cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com