Storage battery provided with bipolar polar plate

A bipolar battery technology, applied in the battery field, can solve the problems of porosity, trachoma, poor corrosion resistance, difficult operation, etc., achieve the effect of reducing production cost, reducing process operation difficulty, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

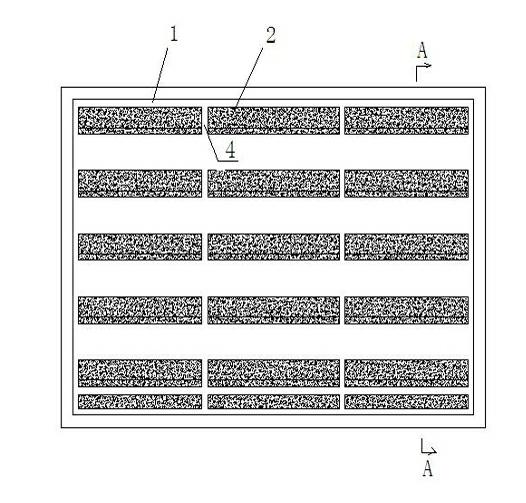

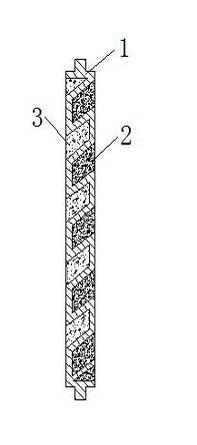

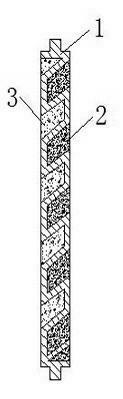

[0015] Such as figure 1 , 2 As shown, the storage battery provided with bipolar plates includes a plate base 1 . Such as figure 2 As shown, the section of the base body 1 is curved in a continuous "S" shape with a wall thickness of 0.6 mm to 1.2 mm, and staggered oblique U-shaped grooves are provided on the front and back sides respectively.

[0016] The oblique U-shaped groove opened on the front of the substrate 1 opens obliquely upwards, the vertical angle of the oblique U-shaped groove is 50o-55o, the mold release slope is 2o-3o, and the positive active material 2 is filled in the groove. The opening of the oblique U-shaped groove on the back of the substrate 1 is obliquely downward, the vertical angle of the oblique U-shaped groove is 50o-55o, the mold release slope is 2o-3o, and the groove is filled with negative active material 3 . After the oblique U-shaped grooves on the front and back of the substrate 1 overlap, the distance between the grooves is 5mm-7mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com