Mode and device for fixing stator and base of motor

A motor stator and fixing method technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as welding of motor stators that are not firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

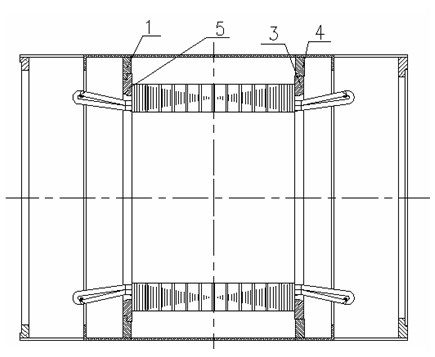

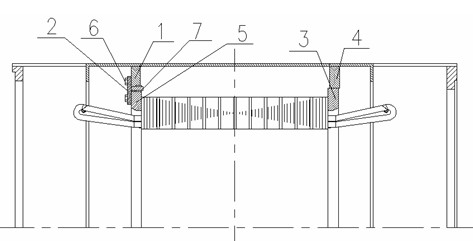

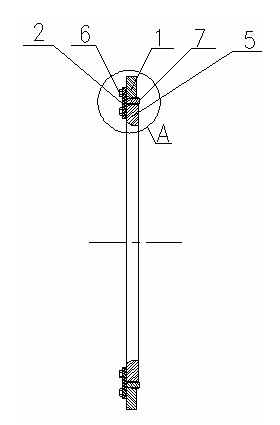

[0036] This embodiment proposes a fixing device for the motor stator and the frame according to the above-mentioned fixing method of the motor stator and the frame, as shown in the attached Figure 2-8 As shown, the partition can be the front partition 1 of the machine base or the rear partition 4 of the machine base, and the pressure ring can be the front pressure ring 5 of the stator or the rear pressure ring 3 of the stator. On the bottom plate, an annular groove is processed on the side of the iron core, and at the same time, 2 to 14 fixing ribs 7 are evenly arranged in the circumferential direction of the annular groove, and grooves are opened on the annular groove of the separator. Welded on the groove; the annular groove corresponding to the annular groove of the partition plate is provided with the annular groove of the pressure ring, and a trapezoidal groove 8 is provided on the annular groove of the pressure ring corresponding to the position of the fixing rib, and th...

Embodiment 2

[0038] This embodiment proposes another fixing device for the motor stator and the machine base according to the above-mentioned fixing method of the motor stator and the machine base. The connection is fixed, as attached Figure 9 As shown, the difference from Example 1 is that the fixing of the diaphragm and the pressure ring is the superposition of the diaphragm and the pressure ring, and screw holes are evenly opened on the ring part superimposed on the diaphragm and the pressure ring, and the diaphragm is directly connected by bolts. Connect and fix with the pressure ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com