Plastic packaging type IPM module installing structure

A mounting structure, plastic-encapsulated technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of lead frame not being in contact with solder joints, product waste, etc., to reduce virtual welding or welding dislocation risk, improve reliability, and reduce the difficulty of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

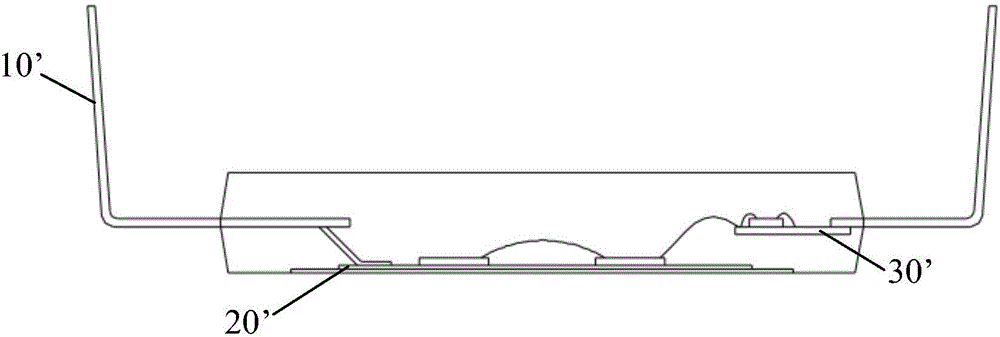

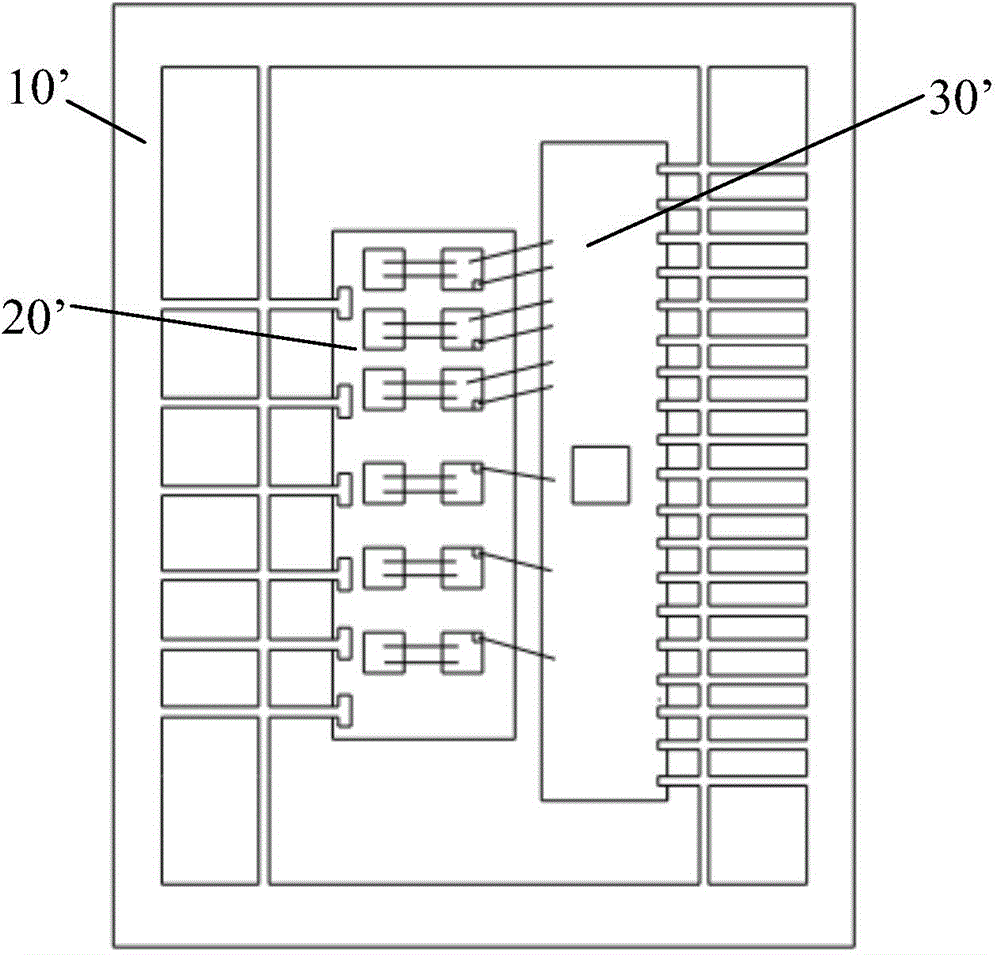

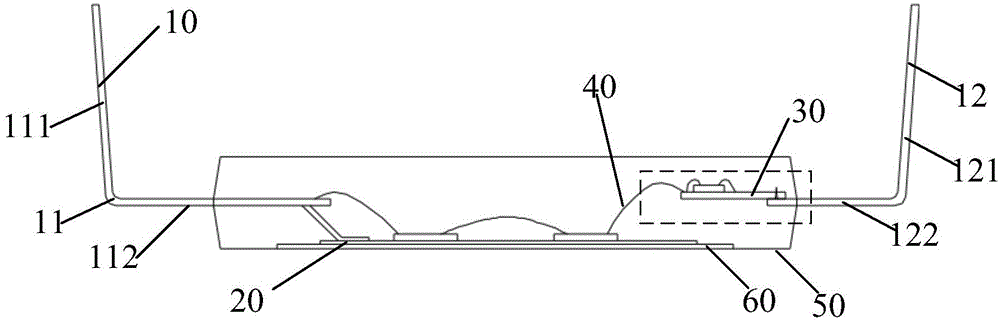

[0025] The invention discloses a plastic-encapsulated IPM module installation structure. The installation structure includes a lead frame group, a DBC board and a PCB circuit board that are fixedly installed and electrically connected with the lead frame group, and the DBC board and the PCB circuit board are electrically connected to each other. Setting, the PCB circuit board is provided with a plurality of welding holes, and the lead frame group is provided with a plurality of welding pins corresponding to the welding holes, and the PCB circuit board and the lead frame group are welded and fixed through the welding holes and the welding pins.

[0026] Preferably, the lead frame group includes a first lead frame group and a second lead frame group, the first lead frame group is welded and fixed to the DBC board, and the second lead frame group is welded and fixed to the PCB circuit board.

[0027] Preferably, the welding pins are arranged on the second lead frame group.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com