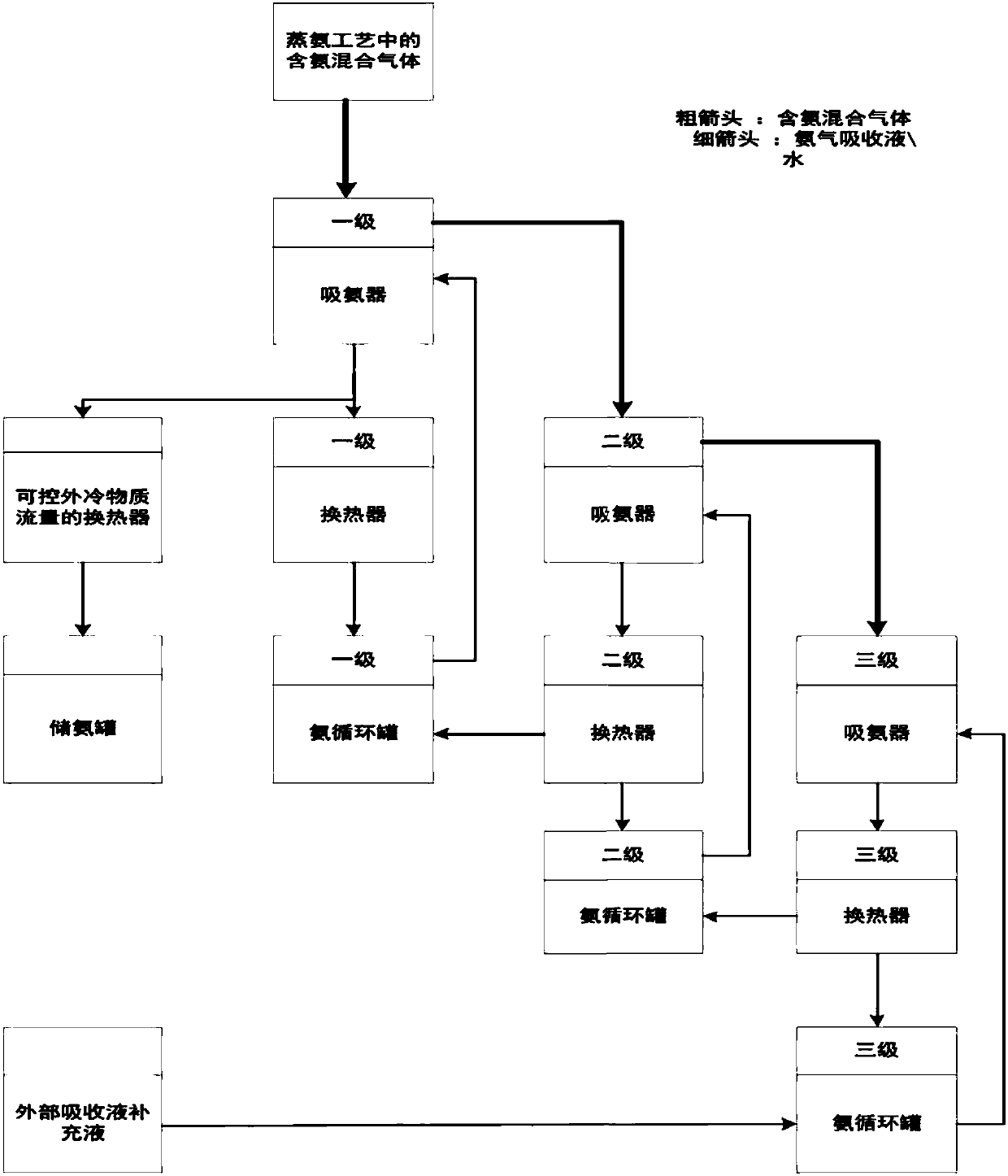

Multistage reverse cycle ammonia absorption process

A process and ammonia recycling technology, applied in ammonia compound, chemical industry, ammonia preparation/separation, etc., can solve the problems of insufficient ammonia absorption, low work efficiency and high process cost, saving labor cost and reducing process cost , the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

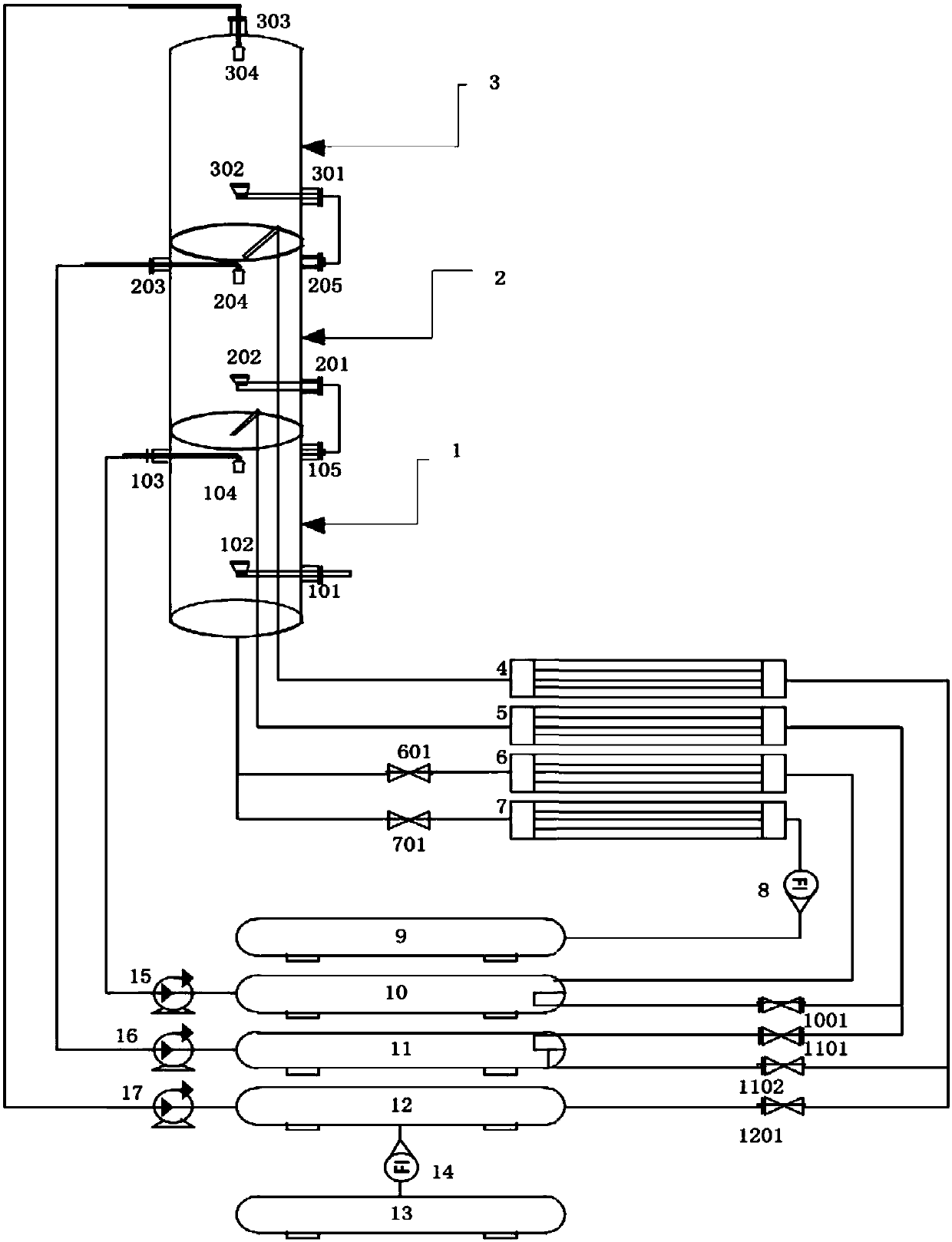

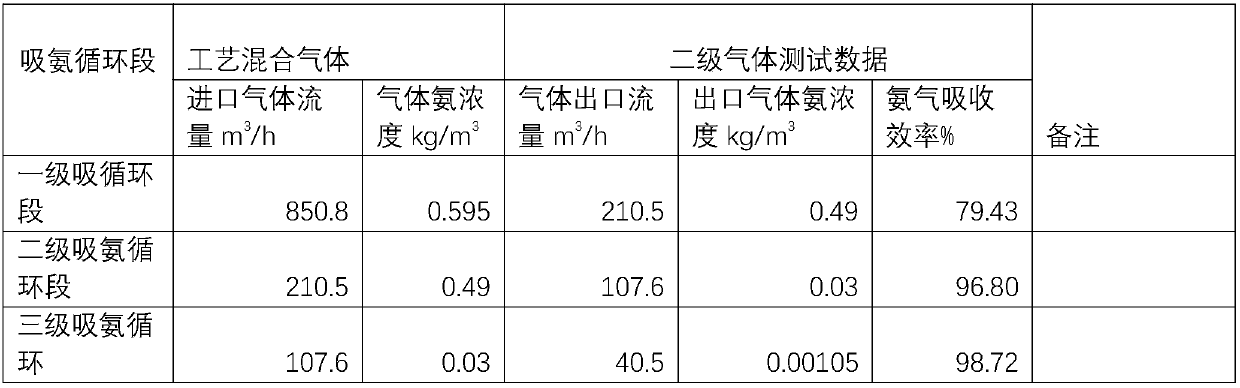

[0053] Such as figure 2 As shown, the ammonia concentration is 0.595kg / m 3 Process gas mixture, according to 850.9m 3 The flow rate of / h is passed into the primary ammonia absorbing monomer 1, and the primary process water pump 15, the secondary process water pump 16, and the tertiary process water pump 17 are turned on simultaneously. The three-stage process water pump 17 pumps the clear water in the external process circulating water tank 13 into the three-stage ammonia absorbing monomer 3; the process mixed gas in the first-stage ammonia absorbing monomer 1 enters the three-stage ammonia absorbing monomer 3, and is absorbed The ammonia-absorbing liquid formed after the clear water is absorbed flows back into the secondary ammonia-absorbing circulating tank 11 and the third-stage ammonia-absorbing circulating tank 12 respectively; Pumped by the secondary process water pump 16 into the secondary ammonia-absorbing monomer 2 to absorb ammonia, the ammonia-absorbing liquid f...

Embodiment 1-2

[0057] Take the operation steps described in Experimental Example 1-1, the difference is: the ammonia concentration is 0.578kg / m 3 Process gas mixture, according to 867.2m 3 The flow rate of / h is passed into the primary ammonia absorbing monomer 1, and the valves that control the return flow of the ammonia absorbing liquid in the branches of each return pipeline are continuously adjusted, and combined with the detection of flowmeter one 8 and flowmeter two 14 Observe, finally make the absorption liquid in the first-level ammonia absorption circulation tank 10 be the ammonia absorption liquid (concentration value: 108.5tt) of high concentration, the absorption liquid in the secondary ammonia absorption circulation tank 11 is the ammonia absorption liquid of medium concentration ( The concentration value is: 57.4tt), and the absorption liquid in the three-stage ammonia absorption circulation tank 12 is a low-concentration ammonia absorption liquid (concentration value: 24.1tt),...

Embodiment 1-3

[0061] Take the operating steps described in Example 1-1, the difference is: the ammonia concentration is 0.604kg / m 3 Process gas mixture, according to 821.6m 3The flow rate of / h is passed into the primary ammonia absorbing monomer 1, and the valves that control the return flow of the ammonia absorbing liquid in the branches of each return pipeline are continuously adjusted, and combined with the detection of flowmeter one 8 and flowmeter two 14 Observe, finally make the absorption liquid in the first-level ammonia absorption circulation tank 10 be the ammonia absorption liquid (concentration value: 102.1tt) of high concentration, the absorption liquid in the secondary ammonia absorption circulation tank 11 is the ammonia absorption liquid of medium concentration ( The concentration value is: 53.8tt), and the absorption liquid in the three-stage ammonia absorption circulation tank 12 is a low-concentration ammonia absorption liquid (concentration value: 22.8tt). The statisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com