Method for liquifying coal mildly

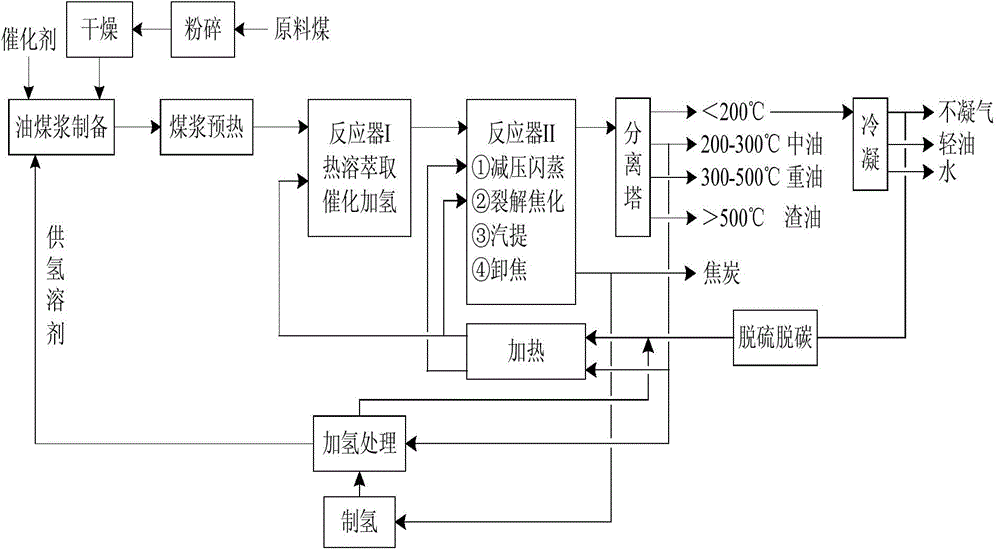

A process method and mild technology, applied in the field of clean energy technology and coal chemical industry, can solve problems such as environmental pollution, low relative output, narrow adaptability of raw materials, etc., to reduce the difficulty of process operation, high energy conversion efficiency, and high added value of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dry and pulverize the Shengli lignite, stir and mix it with the catalyst ferrous sulfide (catalyst / coal=1:20) and the hydrogen donating solvent tetrahydronaphthalene (solvent-coal ratio 3:1) to make oil-coal slurry, heat it to 350°C and pass it into In the reactor Ⅰ, the pressure is 4MPa. After keeping for 30 minutes, it is transported into the reactor Ⅱ for decompression flashing, and then the middle oil steam at 450°C is introduced to purge, and then the non-condensable gas at 450°C is added to further crack and coke, and then pass through Enter water vapor to cool down and strip, and decoke after the end. In this example, high gray coke is not used for hydrogen production. Product yield (dry ash-free basis): light oil yield 14.1%, medium oil yield 16.0%, heavy oil yield 11.4%, residue oil yield 6.4%, non-condensable gas yield 15.3%, water yield 8.3%, coke Yield 28.5%.

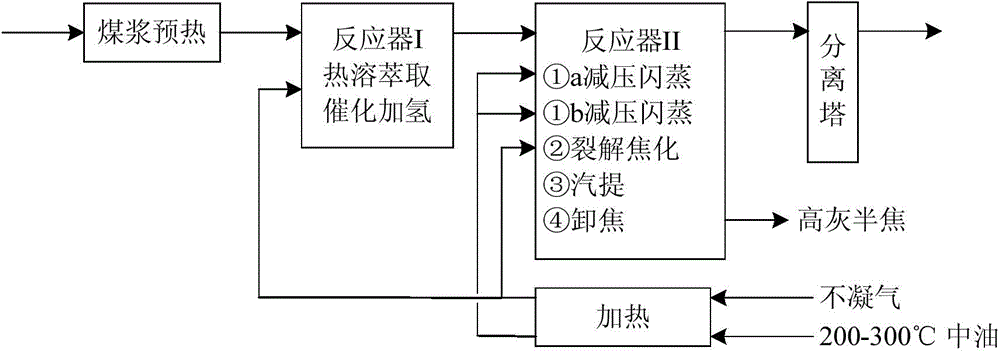

Embodiment 2

[0046] Dry and pulverize Shengli lignite, stir and mix with catalyst ferrous sulfide (catalyst / coal = 1:20), hydrogen-donating solvent anthracene oil (solvent-to-coal ratio 3:1) to make oil-coal slurry, heat to 350°C and pass into the reaction In the reactor Ⅰ, the pressure is 4MPa at this time, a certain amount of anthracene oil hydrogenation tail gas and non-condensable gas are introduced, kept for 30 minutes, and then transported to the reactor Ⅱ for decompression flash evaporation, and at the same time, 450°C medium oil steam is introduced for purging. Continuously inject the slurry into the reactor II(a) for several times, then add non-condensable gas at 450°C to further crack and coke, then pass in water vapor to lower the temperature and strip, and decoke after the end. In this example, high gray coke is not used for hydrogen production. Product yield (dry ash-free basis): light oil yield 11.3%, medium oil yield 13.0%, heavy oil yield 11.7%, residue oil yield 5.7%, non-...

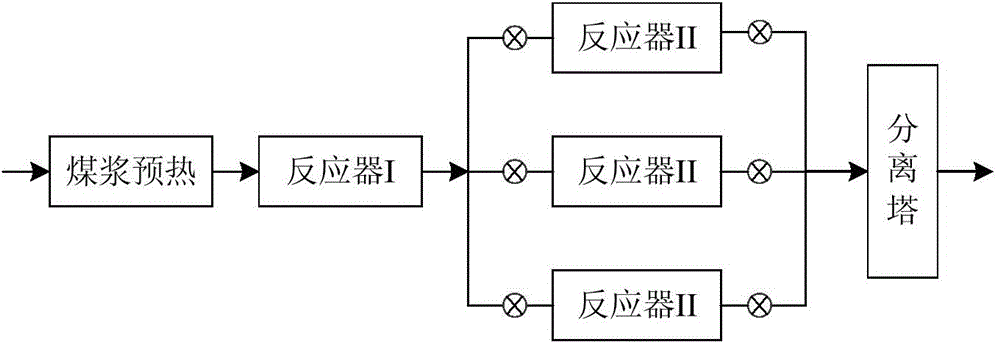

Embodiment 3

[0048] Dry and pulverize Shendong electric power coal, stir and mix with catalyst ferrous sulfide (catalyst / coal = 1:20), hydrogen-donating solvent (20% tetrahydronaphthalene, solvent-to-coal ratio 3:1) to make oil-coal slurry, and heat to After 350°C, it is passed into the reactor Ⅰ, and a certain amount of anthracene oil hydrogenation tail gas and non-condensable gas are passed in, and the pressure is 4MPa. 450°C medium oil steam purge, inject the slurry into the reactor II (a) several times continuously, when the reactor II (a) is almost full, switch the valve to the reactor II (b), at this time the slurry is injected into the reaction Reduced pressure flash evaporation is carried out in the device II (b). Add non-condensable gas at 450°C to reactor II(a) to further crack and coke, then pass in water vapor to lower the temperature and strip, and decoke after the end. Product yield (dry ash-free basis): light oil yield 9.1%, medium oil yield 10.1%, heavy oil yield 9.4%, res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com