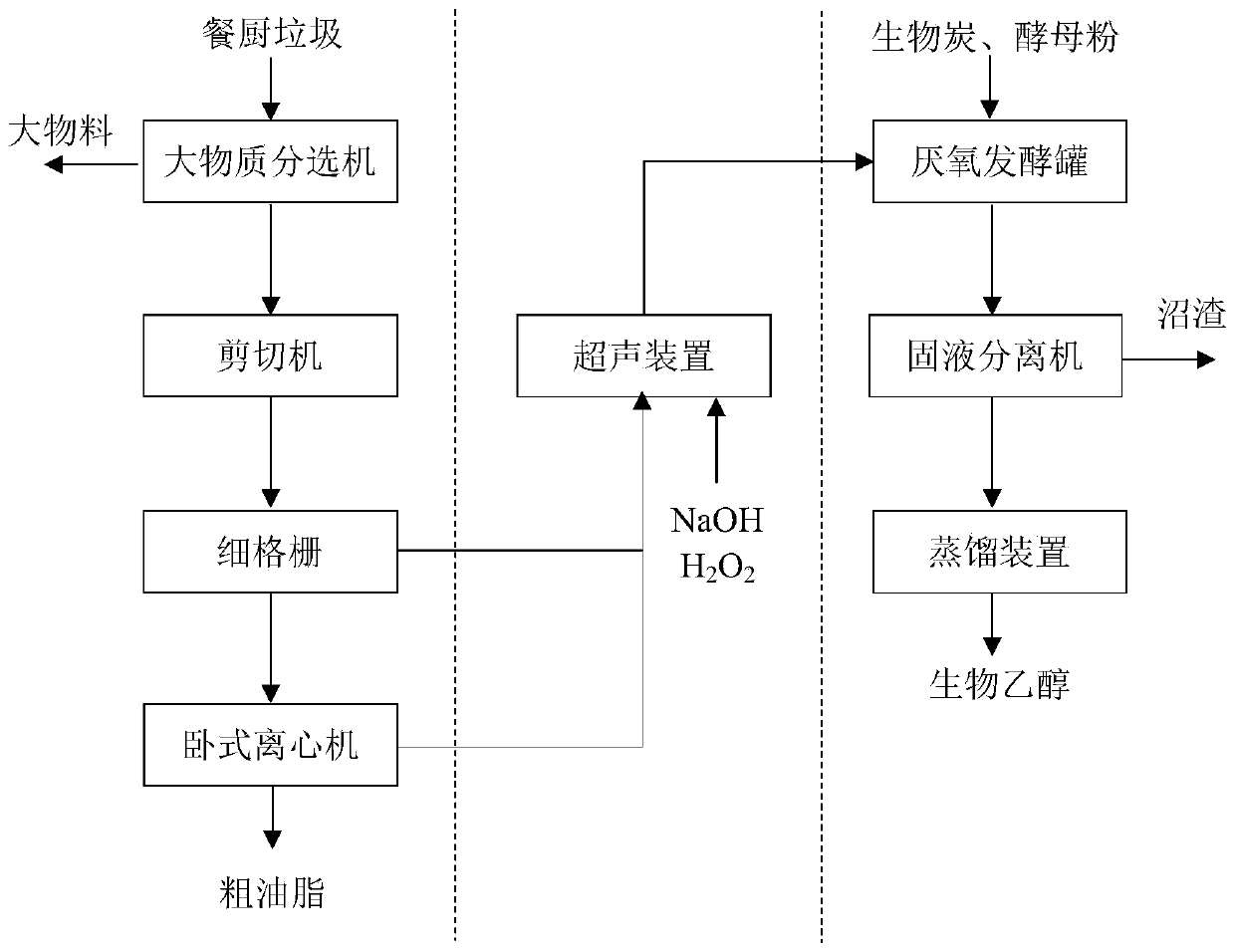

Method for producing bioethanol through anaerobic fermentation of kitchen waste

An anaerobic fermentation, kitchen waste technology, applied in the field of environmental engineering, can solve the problems of extremely high equipment quality requirements, difficult practical application, complex pretreatment process, etc., to achieve both environmental and economic benefits, and improve the abundance of yeast. the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) After the food waste collected and transported by a food waste harmless and resourceful treatment plant has been sorted, crushed, and oil extracted, the particle size of the crushed food waste is below 8mm. The TS of the mixed slurry is 5%, the SCOD is 20000mg / L, and the pH is 6.

[0032] (2) The slurry is transported to an ultrasonic device for joint pretreatment, wherein the ultrasonic frequency is 50 Hz, the temperature is controlled at 20 °C, and the H 2 o 2 The dosage of the solution is 50mg / g TS, and the pH of the system is adjusted to 7 by using 5M NaOH solution. After ultrasonication for 30 minutes, the dissolution rate of kitchen waste was 35%.

[0033](3) After pretreatment, the mixed slurry is pumped into an anaerobic fermentation tank, and activated yeast powder and biochar are added at the same time. Among them, the dosage of yeast powder is 0.1%, and the activation steps of yeast powder include: dissolving in 10 times the mass of distilled water, ke...

Embodiment 2

[0035] After the food waste is sorted, crushed, and oil-extracted, the mixed slurry has a TS of 15%, a SCOD of 60,000 mg / L, and a pH of 4. Dosing H according to the dry matter of kitchen waste 2 o 2 The dosage is 350mg / g TS, the pH of the control system is 11, the ultrasonic device is started, the ultrasonic frequency is adjusted to 250Hz, the ultrasonic time is 90min, the temperature is controlled at 80°C, and the corresponding kitchen waste dissolution rate is 75%. Add activated yeast powder and biochar to the anaerobic fermentation tank, the dosage is 0.3% and 1.5g / gTS respectively, and the BET of biochar is 500m 2 / g, electron transfer ability EDC and EAC are 0.5mmol e / g. The fermentation temperature is 40°C, and the fermentation time is 10 days. The ethanol concentration in the final distillate fraction was 29530mg / L.

Embodiment 3

[0037] After the food waste is sorted, crushed, and oil-extracted, the TS of the mixed slurry is 10%, the SCOD is 40,000 mg / L, and the pH is 5. Dosing H according to the dry matter of kitchen waste 2 o 2 The dosage is 200mg / g TS, the pH of the control system is 9, the ultrasonic device is started, the ultrasonic frequency is adjusted to 150Hz, the ultrasonic time is 60min, the temperature is controlled at 50°C, and the corresponding kitchen waste dissolution rate is 55%. Add activated yeast powder and biochar into the anaerobic fermentation tank, the dosage is 0.2% and 1.0g / gTS respectively, and the BET of biochar is 800m 2 / g, the electron transfer ability EDC and EAC are both 0.9mmol e / g. The fermentation temperature is 35°C, and the fermentation time is 7.5 days. The ethanol concentration in the final distillate fraction was 33530mg / L. The implementation effect is better than that reported in the published patent CN109761465A "A Method for Anaerobic Ethanol Production f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com