Benzene hydrogenation wastewater desulfurization and deamination treatment method aiming at improving deamination and treatment device applying same

A technology for hydrogenation of benzene and waste water, applied in the direction of heating water/sewage treatment, degassed water/sewage treatment, multi-stage water treatment, etc., can solve the problems of affecting the quality of ammonia water, complicated operation, and unstable operation of deamination process, etc. Achieve the effects of simplifying the process flow, improving the quality, reducing the difficulty of process operation and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

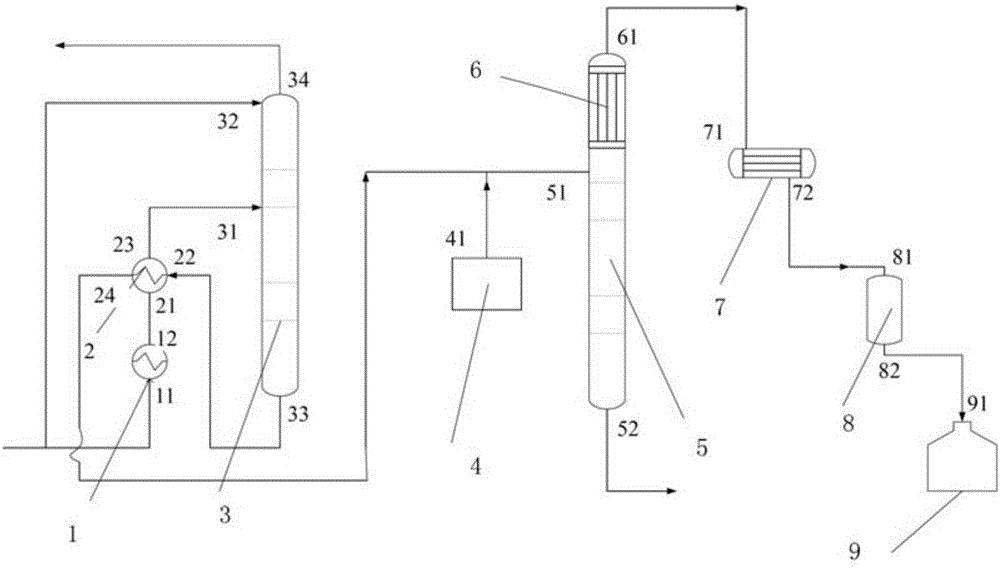

[0042] The desulfurization and deammonification treatment of embodiment 1 benzene hydrogenation waste water

[0043] refer to figure 1, according to the desulfurization and deamination treatment method of benzene hydrogenation wastewater of the present invention, the wastewater from the crude benzene hydrogenation process is heated to 85 to 92 °C after passing through the raw material preheater 1 and the heat exchanger 2, and then enters the deacidification tower 3 for heating Separation, the temperature at the bottom of the tower is 158°C, the temperature at the top of the tower is 60 to 75°C, the hydrogen sulfide is discharged from the top of the tower, and the deacidification still liquid is obtained at the bottom of the tower; the deacidification still liquid is passed through the heat exchanger 2 and the aforementioned crude oil After heat exchange, the wastewater from the benzene hydrogenation process is mixed with NaOH with a concentration of 20% to 40% from the lye tan...

Embodiment 2

[0044] The detection of the ammoniacal liquor that embodiment 2 energy consumption detects and prepares

[0045] The processing method of the present invention can handle sulfide content is 10000~30000mg / l, NH 3 -Wastewater with N content of 6000~20000mg / l, the treatment capacity is 6-11m 3 / h, after treatment (at the bottom of the deamination tower), the ammonia content in the waste water is ≤150mg / l, and the sulfide is ≤50mg / l, and additional 18%-20% ammonia water can be obtained, which can be directly used as other industrial raw materials;

[0046] The method requires 0.33-0.35 tons of steam to treat one ton of waste water, which can save a lot of energy compared with the conventional method; and in the method of the present invention, the acid gas ammonia at the top of the deacidification tower is ≤ 2%, and the water vapor is ≤ 2% , that is, the discharge of three wastes is greatly reduced, and the CODcr of the waste water from the deammonization tower is less than or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com