A packaging method of a QFN fingerprint identification chip

A technology of fingerprint identification and packaging method, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of difficult cutting of lead frames, decreased packaging yield, and easy to break, and solves the problem of easy breakage. , the effect of reducing shear deviation and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

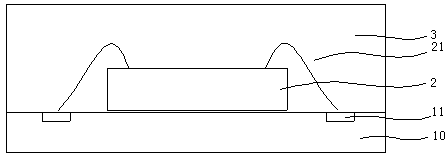

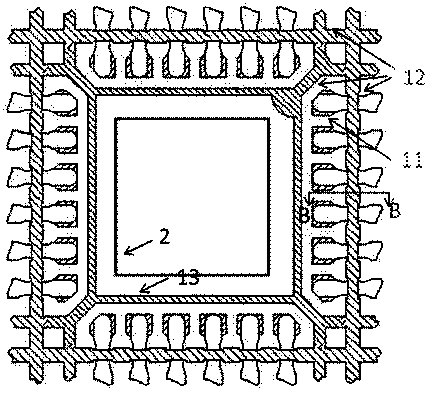

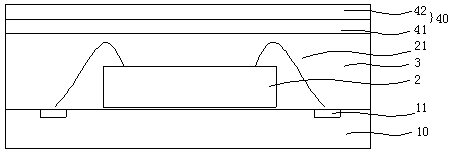

[0078] The packaging structure of the QFN fingerprint identification chip involved in the present invention, such as figure 2 As shown, the chip 2 is arranged in the middle area of the lead frame 10 and fixedly connected with the lead frame 10 . Specifically, the lead frame 10 includes a chip holder, connecting ribs 12 and gold fingers 11, and is the carrier of the chip 2. The chip 2 is fixed on the chip holder, and the aluminum pad on the chip 2 is connected to the gold finger 11 in a one-to-one correspondence using a bonding wire 21. , the gold finger 11 on the remaining side is fixedly connected to the chip holder, and the chip 2 is electrically connected to the gold finger 11 to transmit the electrical signal to the structure of the external PCB board. The chip 2 is a silicon-based fingerprint chip, and in other embodiments, it may also be a chip of other materials or functions. The plastic package 3 wraps the front surface of the lead frame 10 , the chip 2 and the bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com