Electronic commutation brushless direct current and single phase fan circuit and control method thereof

A technology of electronic commutation and AC rectification circuit, which is applied in the direction of electronic commutator, excitation or armature current control, etc., to achieve the effects of reduced winding current, quiet commutation, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

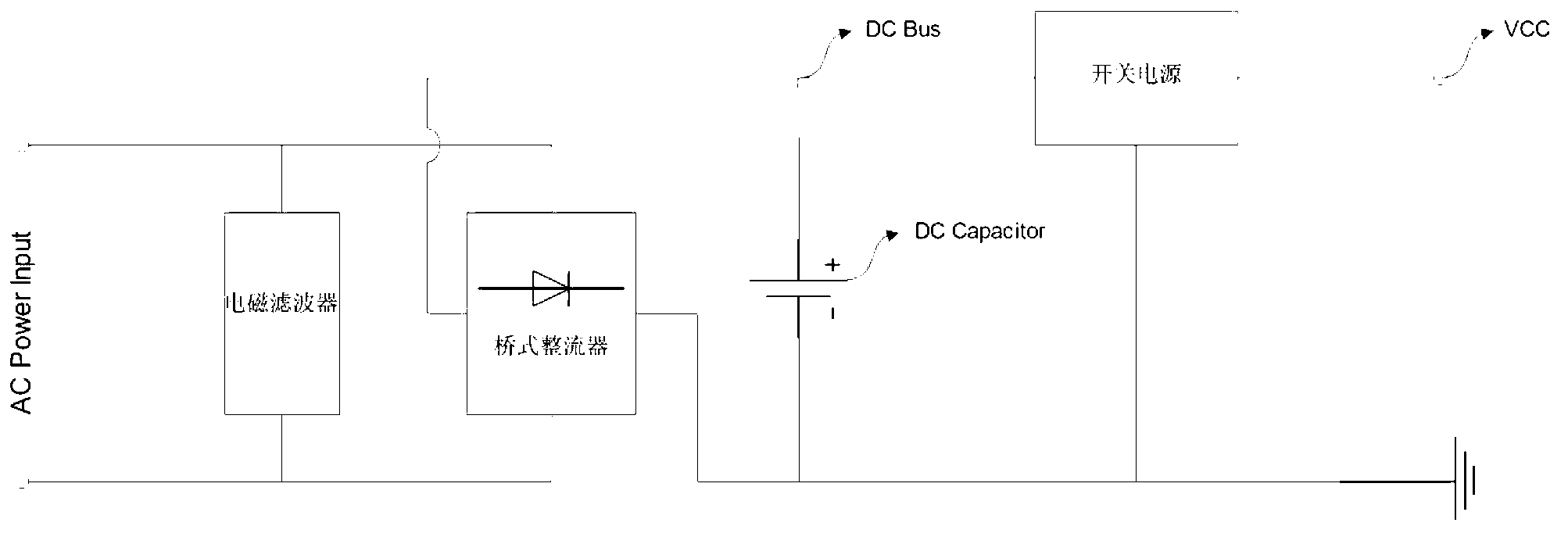

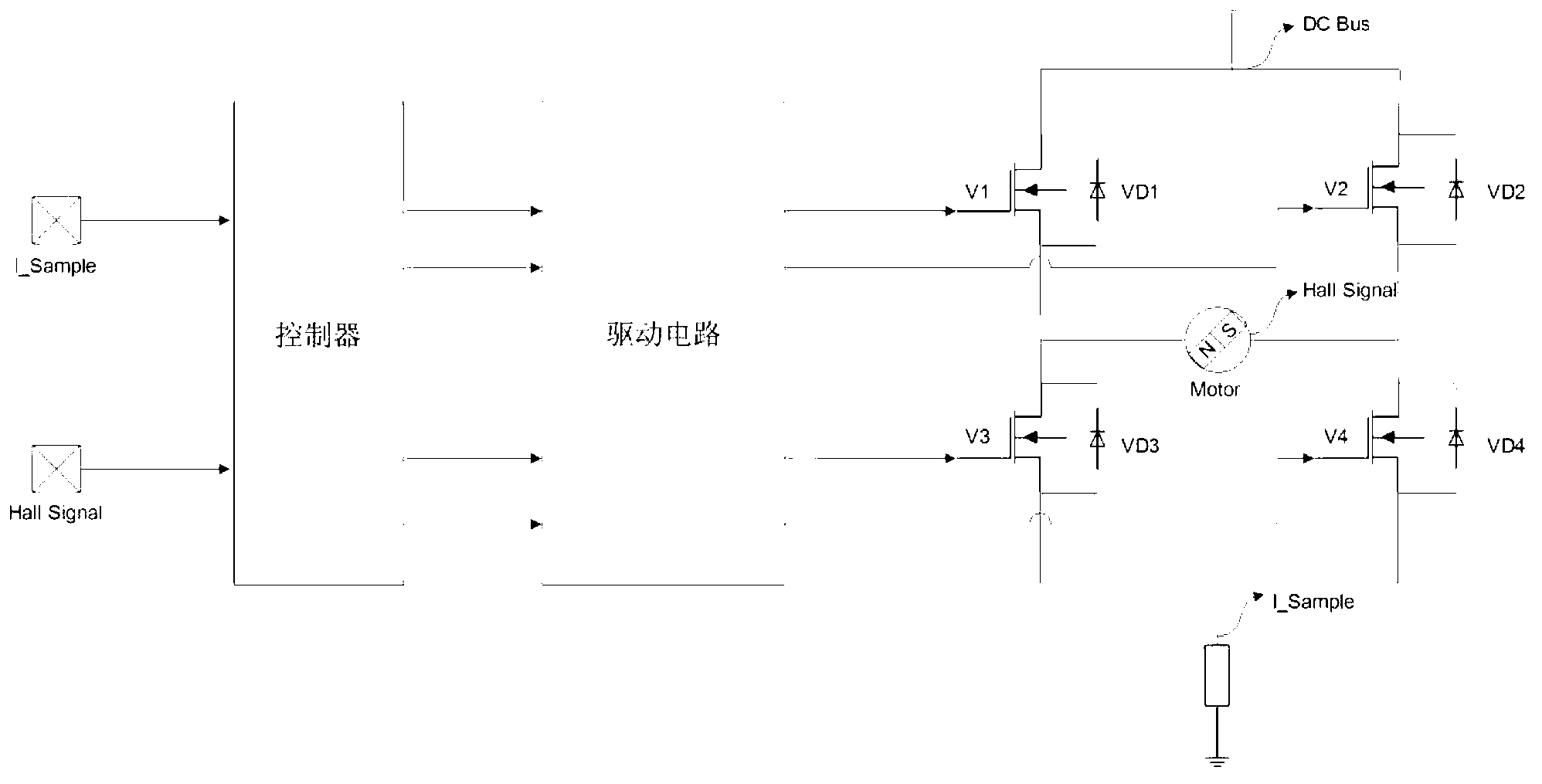

[0022] refer to figure 1 , After the AC mains is filtered by EMC, it is rectified by diode bridge and filtered by capacitors to obtain DC power. The DC power supply voltage is 1.4 times the effective value of the commercial power, that is, in the 220V power supply, the voltage is 310V. In the controller and peripheral circuits, the power supply is usually low voltage. Therefore, it is necessary to step down the rectified low voltage. The switching power supply realizes the conversion from high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com