Double bearing track turnout

A technology for carrying rails and turnouts, applied in the field of rail diversion equipment, can solve the problems of troublesome transportation, large workpiece size, and few diversion conveying methods, and achieve the effect of flexible transportation and fast reversing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

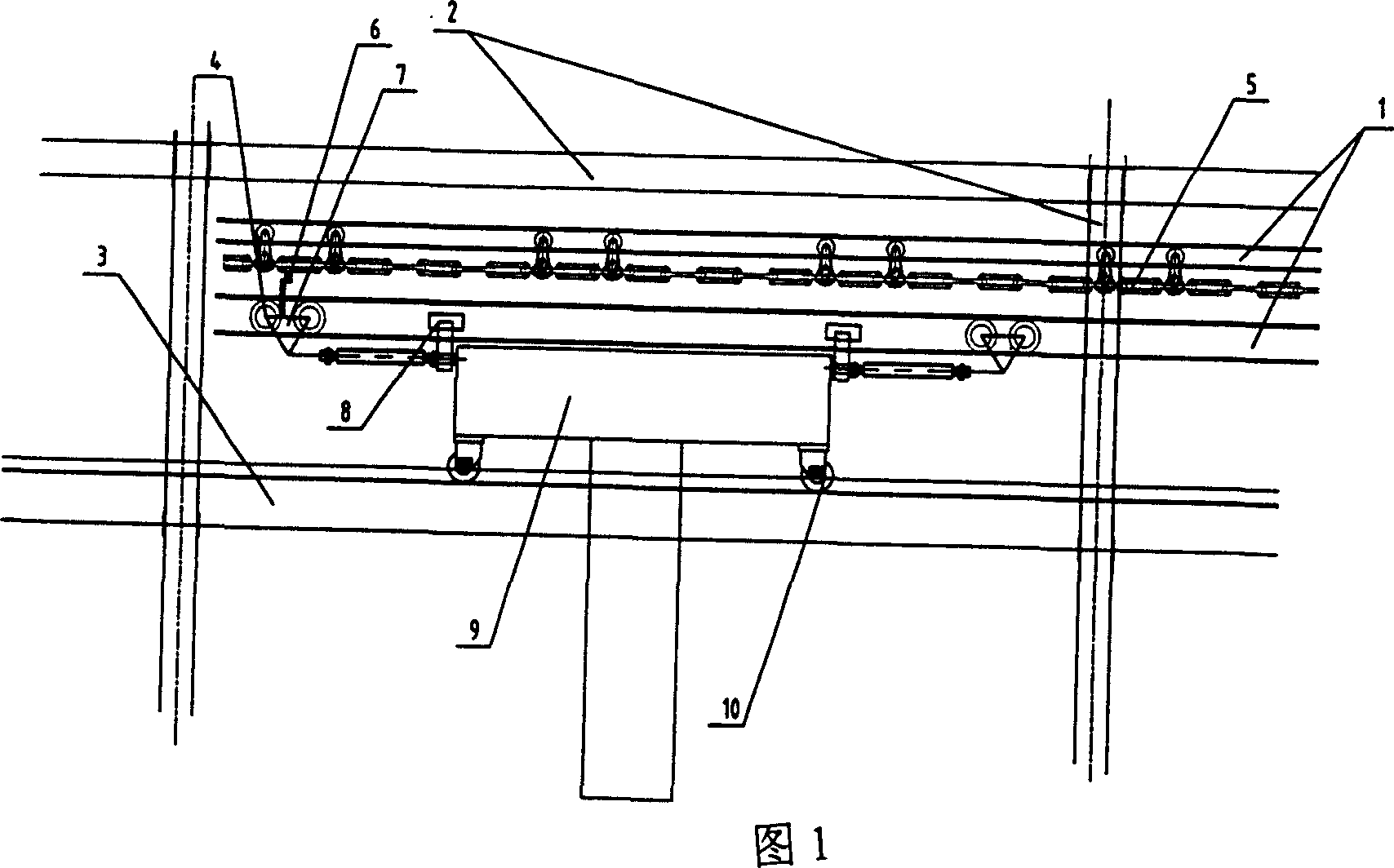

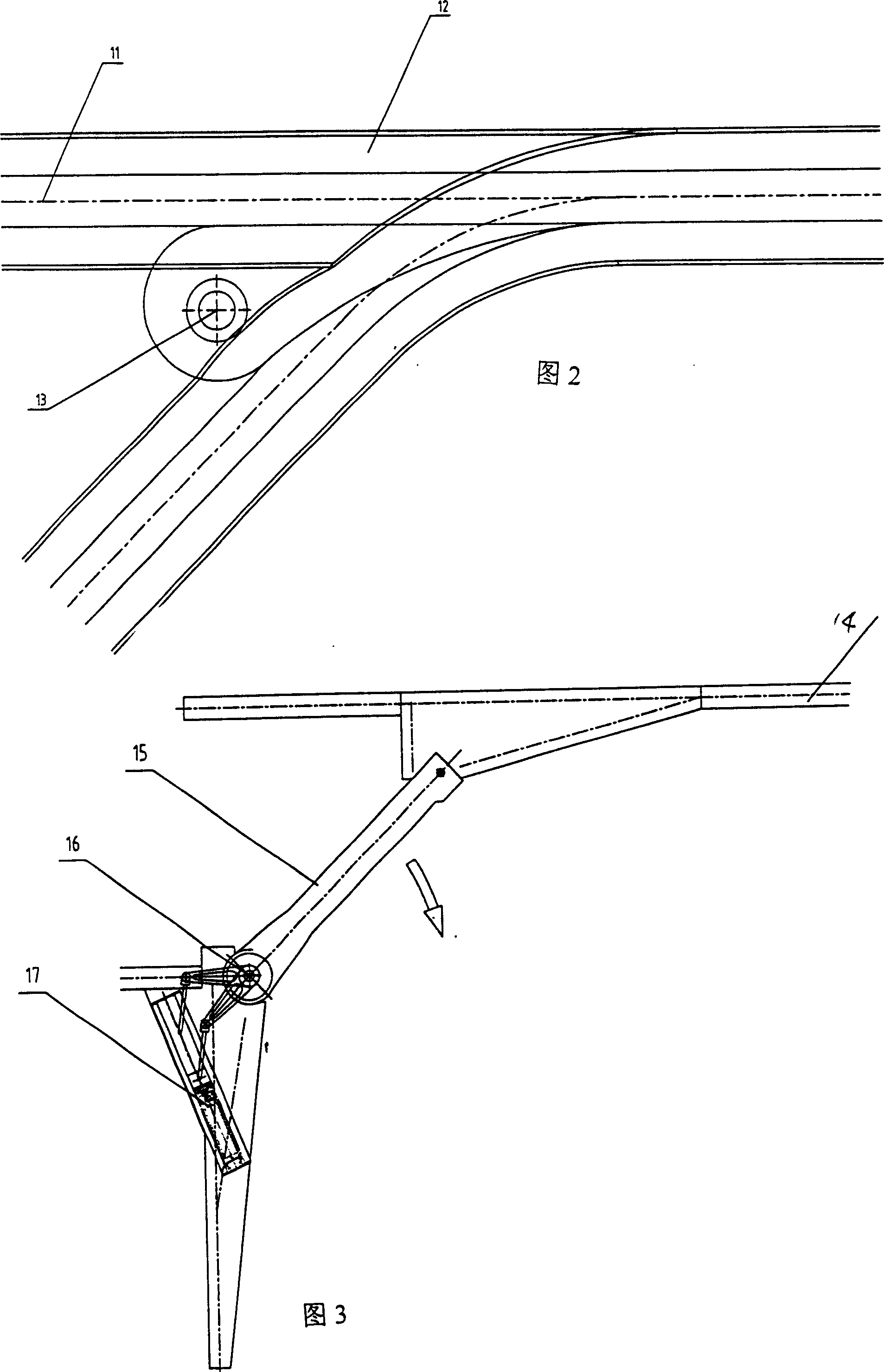

[0011] Comparing with accompanying drawings 1, 2, 3, its structure is that the turnout 1 of the traction chain walking track and the guiding trolley walking track is welded with a steel structure 2, installed in the upper position, and the multifunctional trolley carrying switch track 3 is installed on the guiding trolley walking track. The position directly below is welded with a steel structure 2, and installed in the same steel structure 2 as the upper traction chain travel track and the turnout 1 of the guide trolley travel track. The specific structure of the turnout 1 of the traction chain travel track and the guide trolley travel track is The upper traction chain running track 11 is I-shaped steel, and the turnout 12 of the lower guiding trolley track is two channel steels facing each other. The turnout guiding the trolley walking track is connected to the tongue 13 by bolts; the multifunctional trolley carries the switch track 3. The structure is that the turnout is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com