Reversing machine and reversing method thereof

A technology of reversing machines and reversing rollers, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve problems such as jamming, inclination of butt joint rollers, and heavy mass of sterilization trays, etc., to achieve increased stability Sexuality, cost reduction, and the effect of shortening the itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

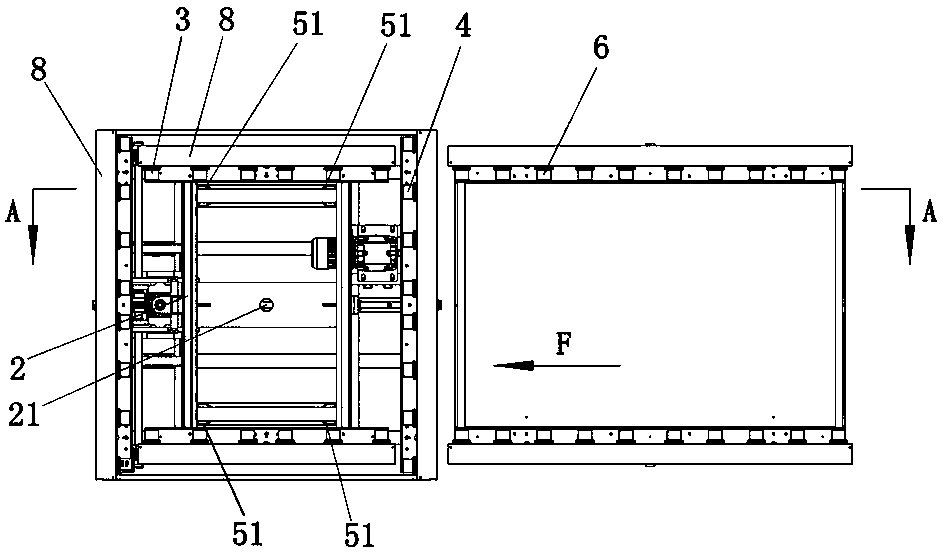

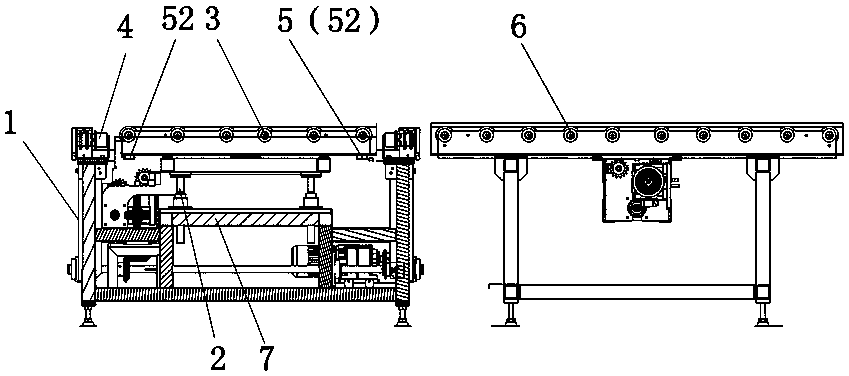

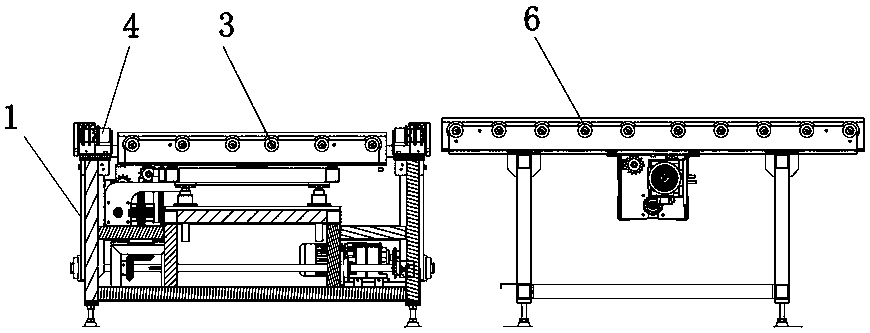

[0029] Figure 1 to Figure 3 An embodiment of the reversing machine of the present invention is shown. The reversing machine of this embodiment includes a frame 1, a jacking mechanism 2, a transition track 3 and a reversing track 4 vertically docked with the transition track 3, and the reversing The track 4 is arranged on the frame 1, the transition track 3 is located on the upper side of the jacking mechanism 2 and is connected with the jacking mechanism 2, the frame 1 is provided with a base 7 and a movable supporting device 5 for supporting the transition track 3, The jacking mechanism 2 is installed on the base 7 .

[0030] The reversing machine is equipped with a movable support device 5 on the frame 1. When the material to be reversed (such as a fully loaded sterilization tray) is transferred to the transition track 3, the movable support device 5 can be used to provide stability for the transition track 3 in advance. The support to complete the reliable positioning of ...

Embodiment 2

[0037] Such as Figure 4 As shown, the commutation method of the present embodiment commutator comprises the following steps:

[0038] S1. The rigid support block 52 protrudes to provide support for the transition rail 3: the jacking cylinder 21 drives the transition rail 3 to rise, and then each telescopic cylinder drives each rigid support block 52 to extend below the transition rail 3, and finally the jacking cylinder 21 drives the transition The track 3 is lowered onto each rigid support block 52; through this step, the rigid support block 52 provides reliable support for the transition track 3 in advance, avoiding the subsequent inclination of the material to be reversed when it enters the transition track 3, and ensuring that the material to be reversed can be stable. , smoothly transported to the transition rail 3; the transition rail 3 needs to be at the same height as the upstream conveying rail 6 after descending to each rigid support block 52, which is conducive to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com