Directional control valve driven by hydraulic pressure

A technology for directional control valves and water pressure, applied in fluid pressure actuators, valve details, valve devices, etc., can solve problems such as high vaporization pressure, material corrosion, wire drawing erosion, etc., and achieve component cost reduction, long service life, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

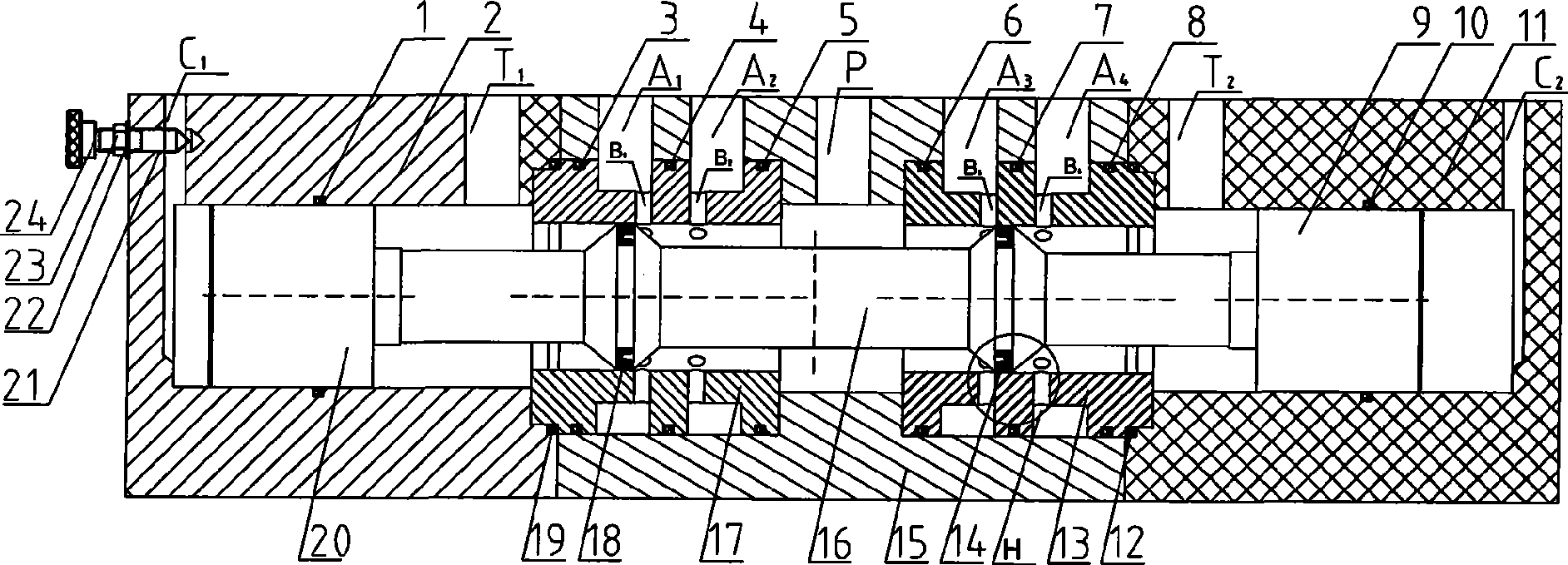

[0024] Refer to attached picture. The present invention is provided with a valve seat 15, and the valve seat is respectively provided with a first water port A from left to right. 1 , the second water port A 2 , Pressure water inlet P, third water outlet A 3 , the fourth water outlet A 4 ;

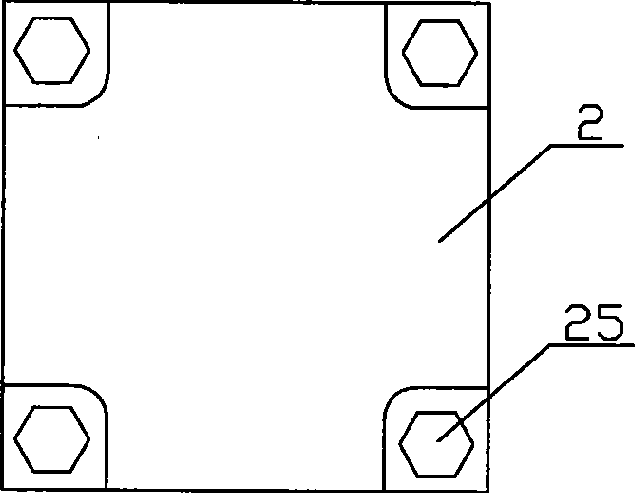

[0025] The directional control valve is also provided with a left valve cover 2 connected to the left side of the valve seat and a right valve cover 11 connected to the right side of the valve seat, and the left valve cover 2 is provided with a first pilot water port C from left to right 1 , the first outlet T 1 , the right valve cover 11 is provided with a second pilot water hole C from right to left 2 , the second outlet T 2 ; The left bonnet 2 and the right bonnet 11 are fixed to the left and right sides of the valve seat 15 with bolts 25, respectively, so that the installation is simpler.

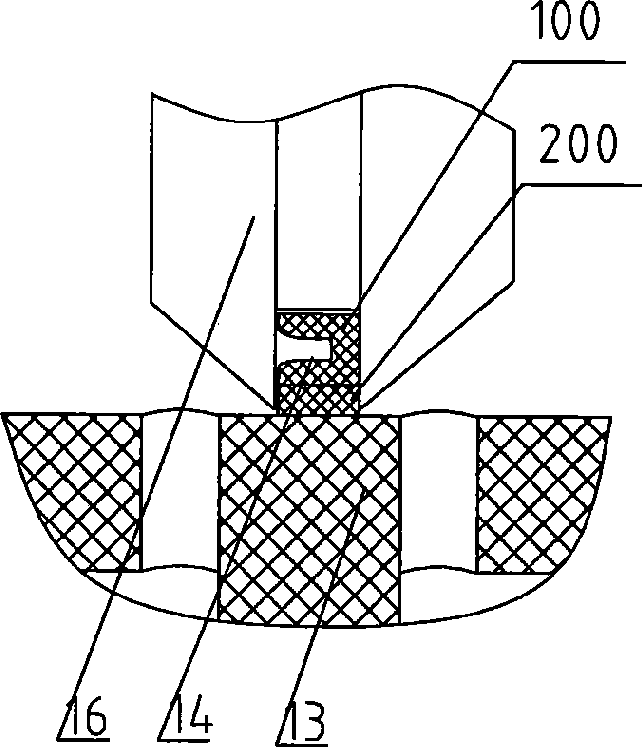

[0026] Described directional control valve installs the first porous ring 17 in the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com