Closed type open commutator

A commutator, closed technology, applied in the direction of instruments, measuring devices, test/calibration devices, etc., can solve the problems of no open state, inaccurate weighing, etc., achieve stable flow state, stable commutation process, and avoid splashing The effect of water and internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the present invention, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the following description is only for the convenience of explaining the present invention, not as a specific limitation on its scope.

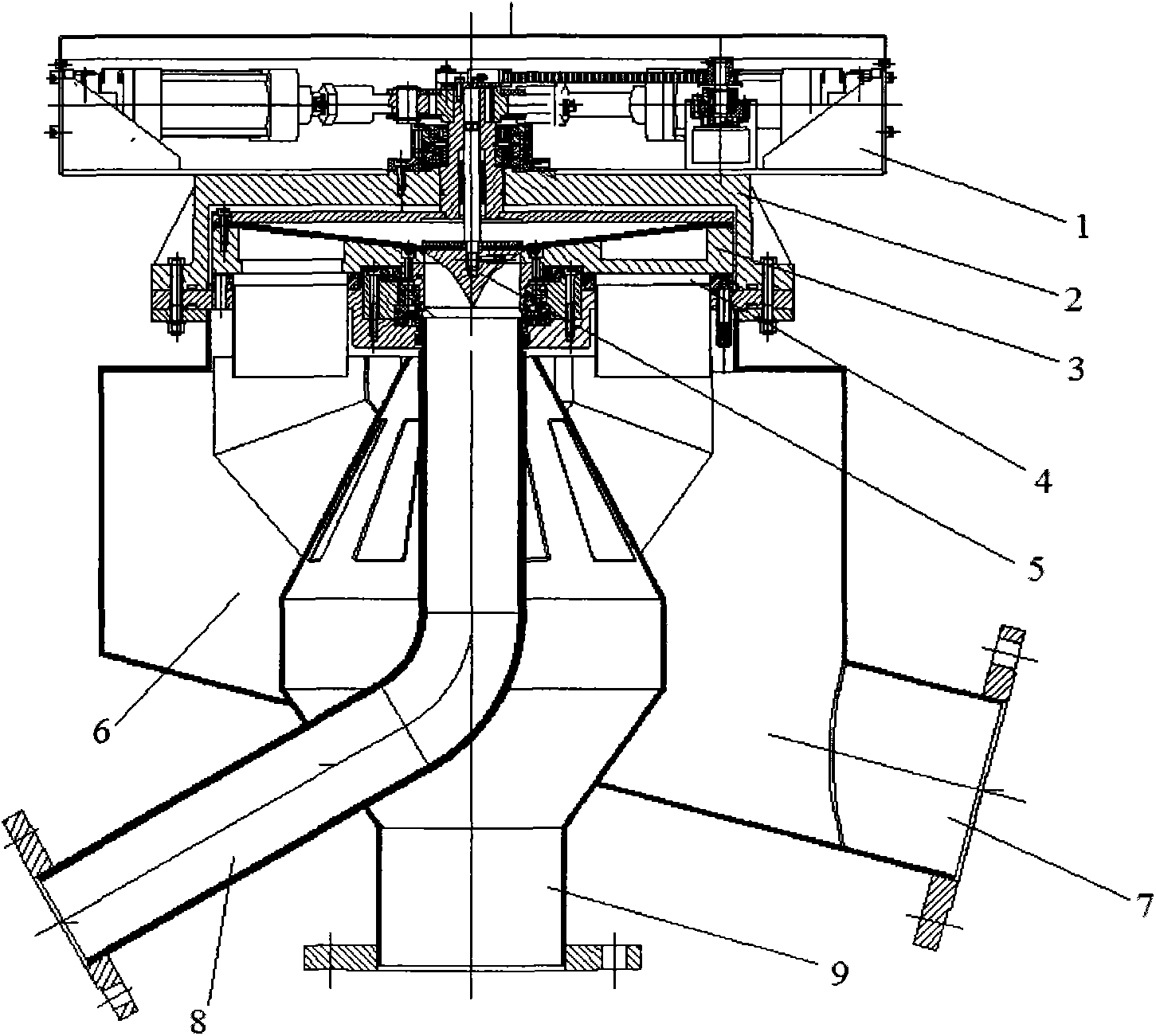

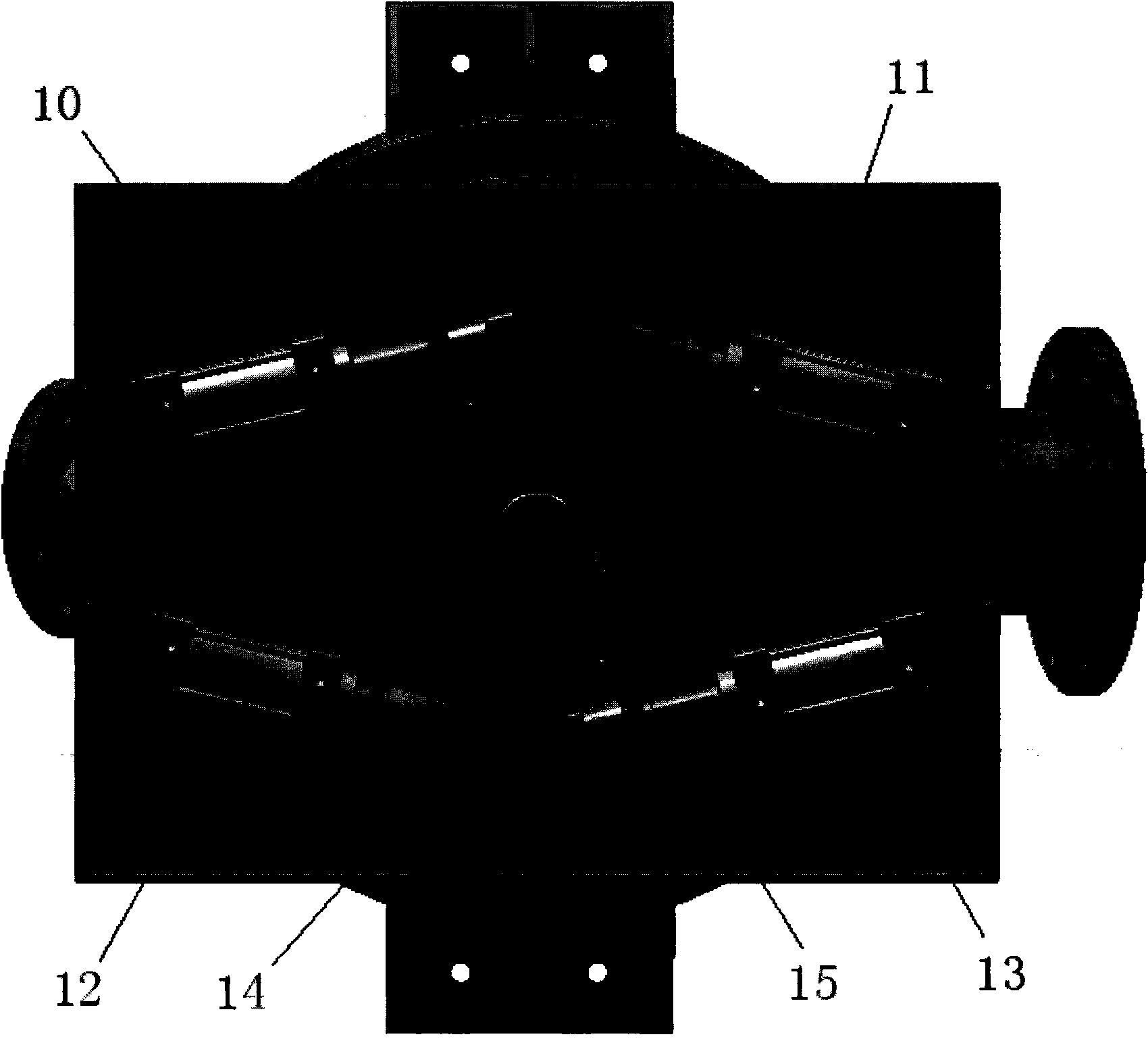

[0019] like figure 1 Shown is the sealed open commutator of the present invention, the open commutator includes a control box 1, the control box 1 includes components that provide power for the commutation and control components that control the commutation, The control box 1 is located at the uppermost part of the steering gear. According to the external control signal, the control box adjusts the flow direction of the liquid in the commutator to realize the commutation; There are a number of nozzles evenly distributed on the disk on the rotating disk, and the liquid flows out from the nozzles, preferably, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com