Grinding device of licker-in grinding and covering machine

A technology for grinding licker-in rollers and grinding, which is applied in the directions of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc. Fixing and moving are prone to problems such as crawling and jittering, so as to achieve the effect of reducing grinding wheel correction devices, high lateral reciprocating motion accuracy, and smooth commutation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

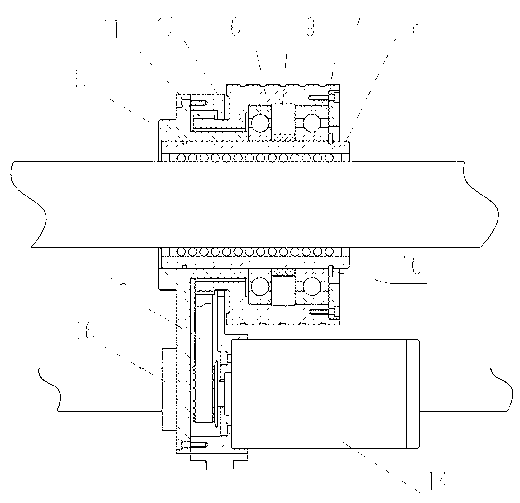

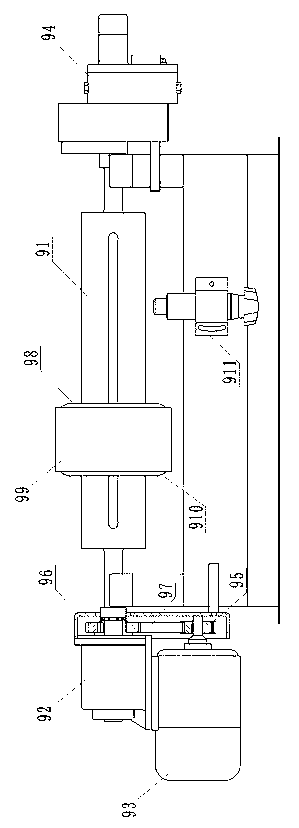

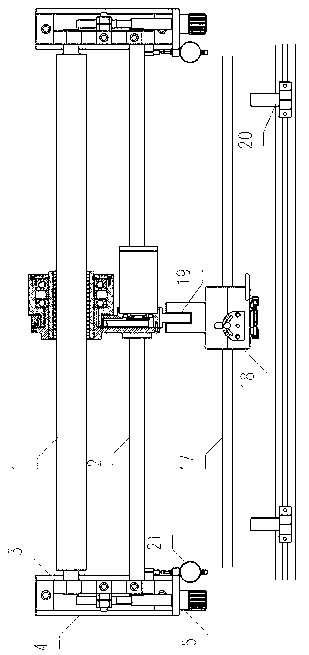

[0024] like figure 2 , image 3 As shown, they are respectively a schematic diagram of the main structure of the grinding device of the licker-in machine of the present invention, and a schematic diagram of the partially enlarged structure of the grinding head unit.

[0025] A grinding device for a licker-in machine, comprising a grinding head unit, a roller unit, and a power unit. The roller 1 and the guide rod 2 are arranged in parallel, and the two ends are respectively installed on the bottom plate of the roller seat 4 through the roller support 3; the grinding head unit includes a grinding head, a high-precision ball bearing 7, a high-precision linear bearing 8, and a linear bearing 16 , the front part of the grinding head unit is installed on the main roller 1 through a high-precision linear bearing 8, and the rear part is installed on the guide rod 2 through a linear bearing 16, and is driven by a power unit to reciprocate along the main roller 1 and the guide rod 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com