Power-saving control system of double housing planer

A gantry planer and power-saving control technology, which is applied in the direction of planing machines, manufacturing tools, planing and inserting devices that can be installed on machine tools, etc., can solve the problems of large maintenance, huge equipment, and workpieces rushing out of the machine bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] A power-saving control system for a planer is composed of hardware and software. The hardware part includes cabinet 1 and the main circuit unit installed in cabinet 1, VVVF control unit of frequency converter, PLC input and output unit of programmable controller, Knife lift and indicator light unit and relay protection unit; the outer dimension of the cabinet 1 is 1600mm×2000mm×700mm, and the lower part of the cabinet 1 is provided with multiple input and output terminal blocks, which are connected to the relevant parts and power supply of the gantry planer.

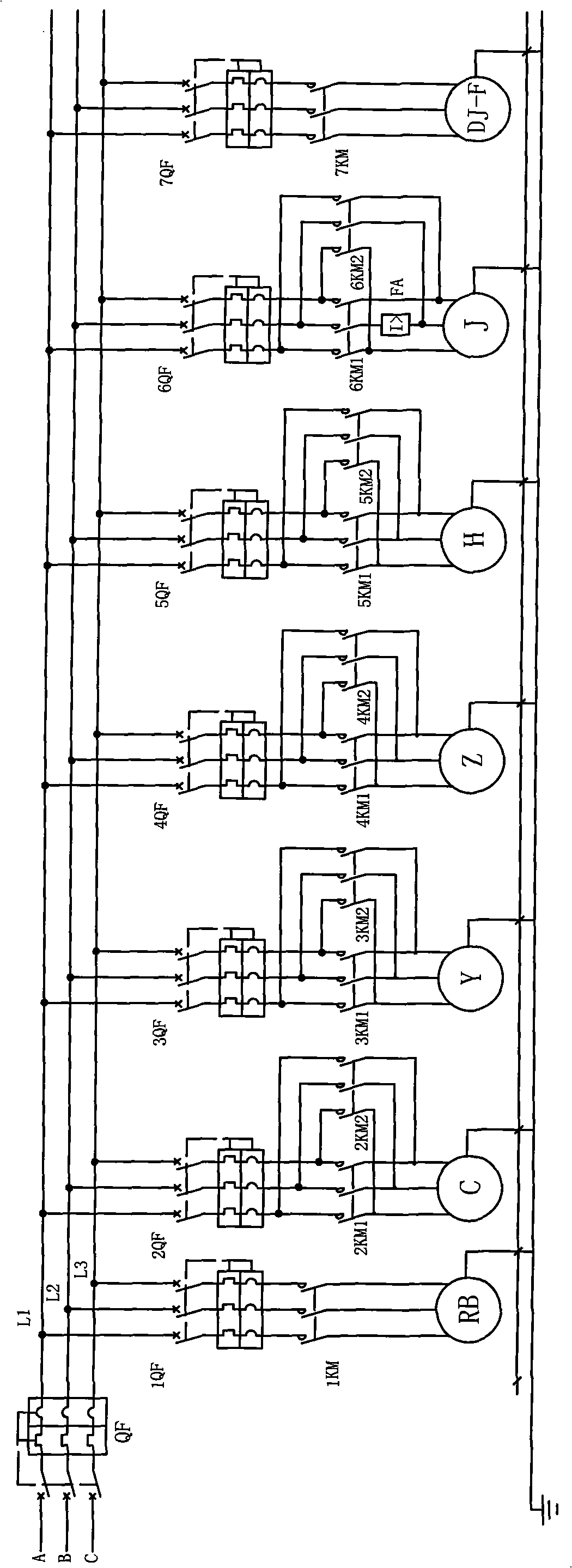

[0058] The main loop unit, such as figure 2 Shown, including main circuit breaker QF, lubrication motor circuit breaker 1QF, vertical knife rest motor circuit breaker 2QF, right knife rest motor circuit breaker 3QF, left knife rest motor circuit breaker 4QF, cross beam lifting motor circuit breaker 5QF, cross beam clamping motor Circuit breaker 6QF, motor fan circuit breaker 7QF and contactors 1KM, 2KM1 and 2KM2, 3KM1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com