A swing arm type pulse continuously variable transmission

A continuously variable transmission and swing arm technology, applied in transmission boxes, transmissions, components with teeth, etc., can solve the problems of low speed ratio, irregular changes, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, a preferred embodiment of the swing arm type pulse continuously variable transmission of the present invention will be described in detail below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not cover the protection scope of the present invention. have any restrictions.

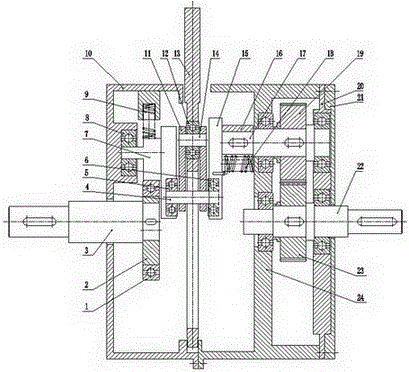

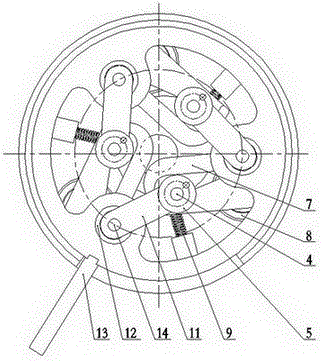

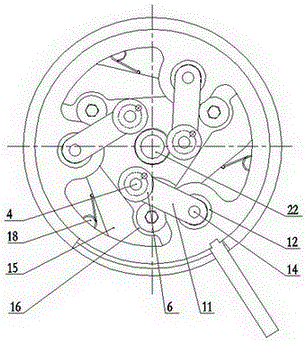

[0015] like Figure 1 to Figure 3 The illustrated embodiment of the swing arm type pulse continuously variable transmission according to the present invention includes a transmission section, an output section and a speed ratio adjusting section. The transmission part includes input shaft 3, eccentric wheel 2, eccentric wheel rolling bearing 1, transmission swing arm 7, swing arm bearing 8, transmission swing arm spring 9, transmission mechanism box 10; output part includes output swing arm 15, overrunning clutch 16. Output swing arm spring 18, output transmission shaft 17, out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com