Combined wedge block mechanism, lever-type anti-exceeding lock catch and automobile anti-reversed sliding device

A combined and lever-type technology, which is applied in the direction of mechanical equipment, toothed components, belts/chains/gears, etc., can solve problems that cannot reverse smoothly downhill, and cannot effectively prevent passive rotating parts from surpassing active rotating parts Speed, the vehicle can not be changed smoothly and other problems, to achieve the effect of simple structure, improved work performance and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

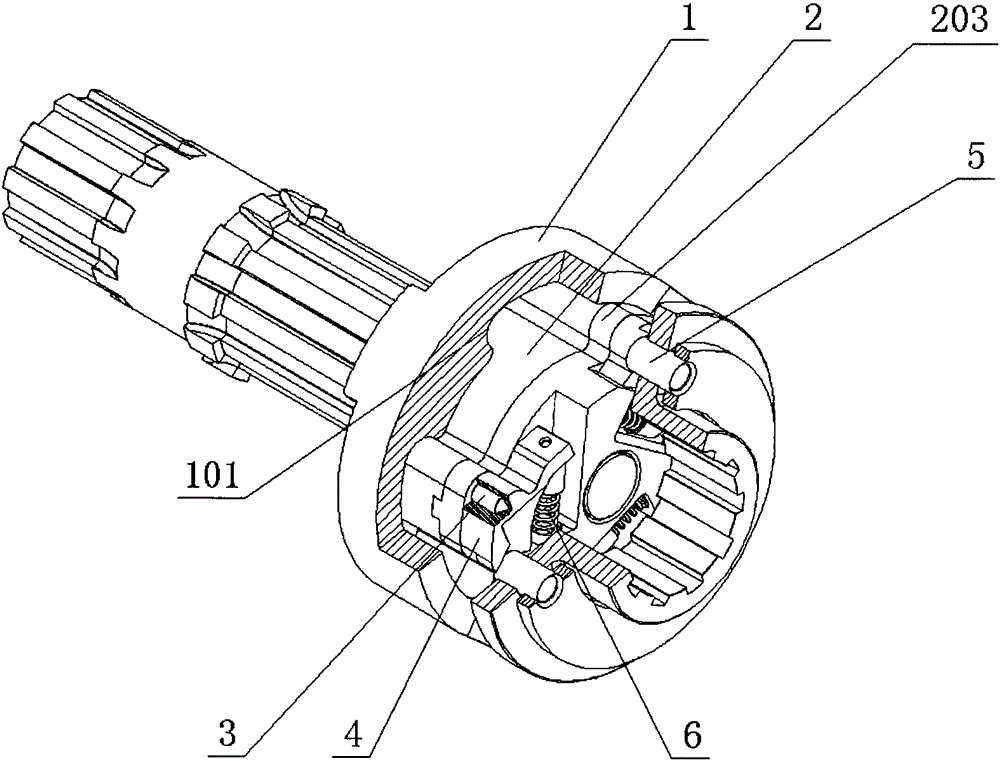

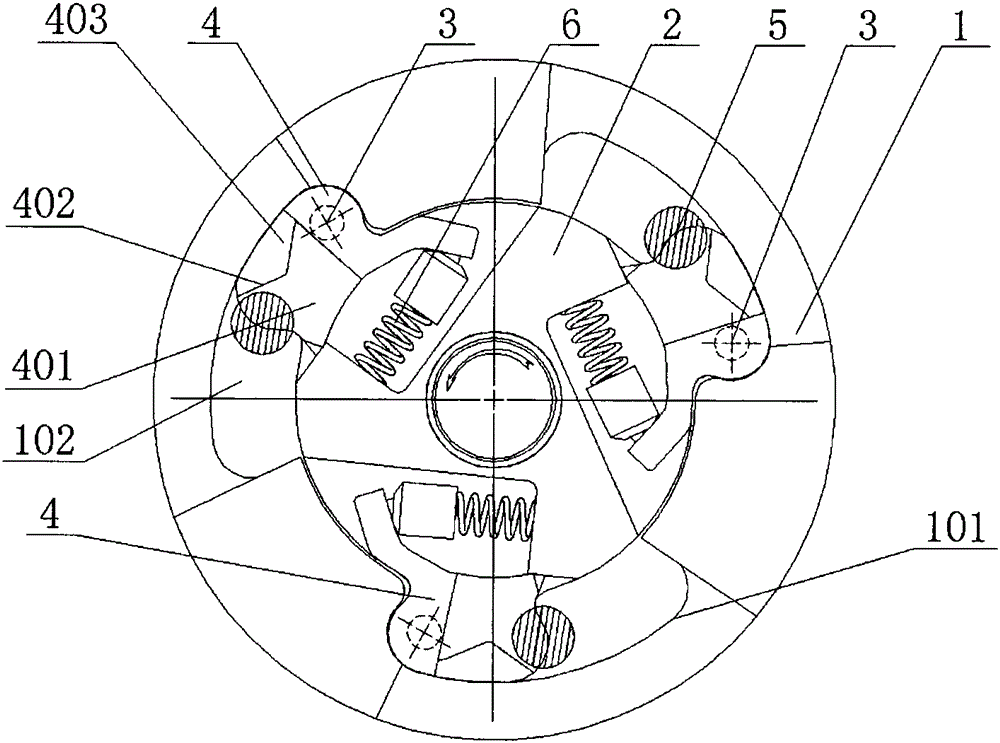

[0052] The technical scheme adopted by the combined wedge mechanism proposed by the present invention is: the passive rotating part 1 and the active rotating part 2 form a gap coupling, the inner cam 101 of the passive rotating part 1 and the outer cam of the active rotating part 2 203 transmits the movement of the positive and negative rotation directions, and the inner cam 101 and the outer cam 203 are provided with a very large cam fit gap 102. The large fit gap results in a larger free rotation stroke and intermittent pause time of rotation, with intermittent Bi-directional drive functions such as figure 1 , image 3 shown.

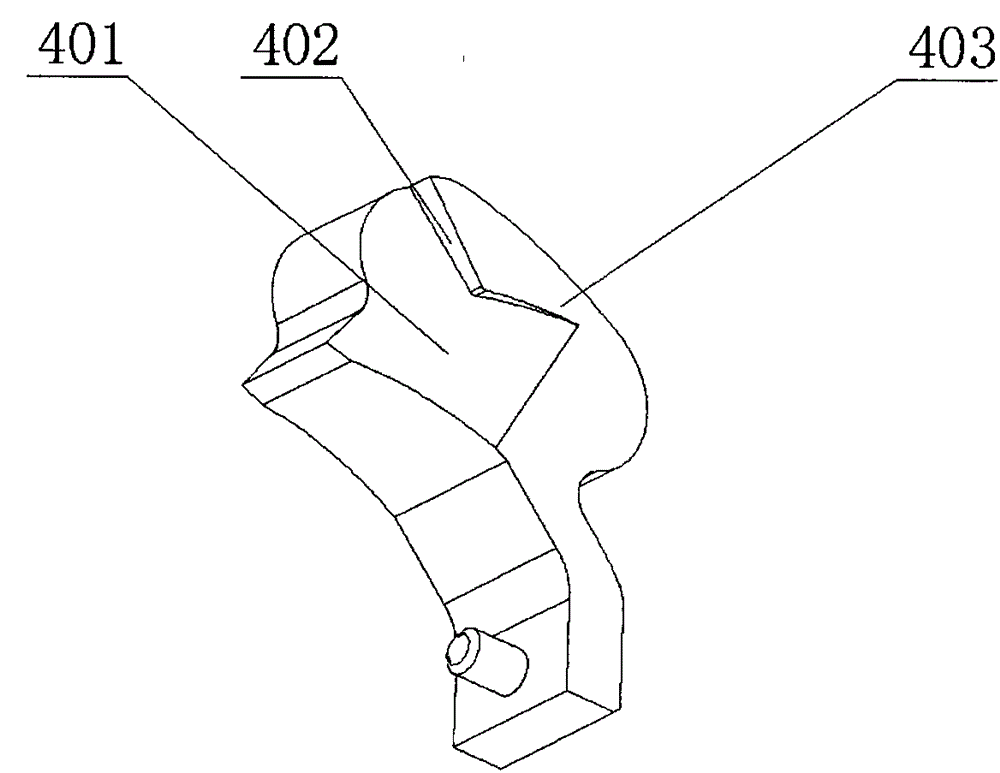

[0053] Its main part, the wedge 4, is provided with a hinged mounting hole and a return spring mounting fulcrum, and the wedge 4 is hingedly mounted on the active rotating part 2, such as figure 1 , image 3 As shown, it rotates together with the active rotating part 2. Wedge 4 is also provided with wedge-shaped working slope 401, guiding slope 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com