Reciprocating type pressurizer reversing device and application thereof

A technology of reversing device and supercharger, which is applied in the direction of fluid pressure actuating device, fluid pressure converter, servo motor assembly, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

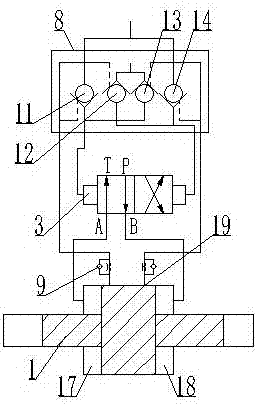

[0017] Such as figure 1 As shown, a reciprocating supercharger includes a first booster cylinder 1 , a first hydraulic control reversing valve 3 , and a hydraulic control check valve group 8 . The hydraulic control check valve group 8 includes a first hydraulic control check valve 11 , a second hydraulic control check valve 12 , a third hydraulic control check valve 13 and a fourth hydraulic control check valve 14 . The first pressurized cylinder includes a left piston chamber 17 and a right piston chamber 18, and the left and right piston chambers are equipped with an automatic control port 19. The first hydraulic control reversing valve 3 is a two-position four-way hydraulic control reversing valve, A and B ports are respectively connected to the end faces of the left and right piston chambers of the first booster cylinder 1, and the left pilot port is connected to the first hydraulic control check valve 11 and The third hydraulic control check valve 13, the right pilot por...

Embodiment 2

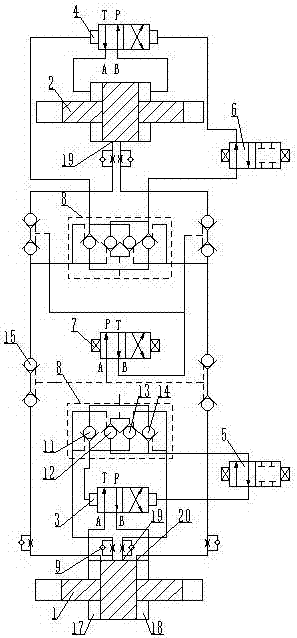

[0020] Such as figure 2 As shown, a single multi-control freely switchable reciprocating supercharger includes a first booster cylinder 1, a second booster cylinder 2, a first hydraulically controlled reversing valve 3, and a second hydraulically controlled reversing valve 4, each group The pressurized cylinder and the hydraulic control reversing valve match the hydraulic control check valve group 8, the hydraulic control check valve group 8 includes the first hydraulic control check valve 11, the second hydraulic control check valve 12, the third hydraulic control check valve Valve 13, the fourth hydraulic control check valve 14, the pressurized cylinder includes a left piston chamber 17 and a right piston chamber 18, the left and right piston chambers of the first pressurized cylinder are opened with an automatic control port 19 and an external control port 20, and the external control port is located at the automatic control port On the outside, the left and right piston c...

Embodiment 3

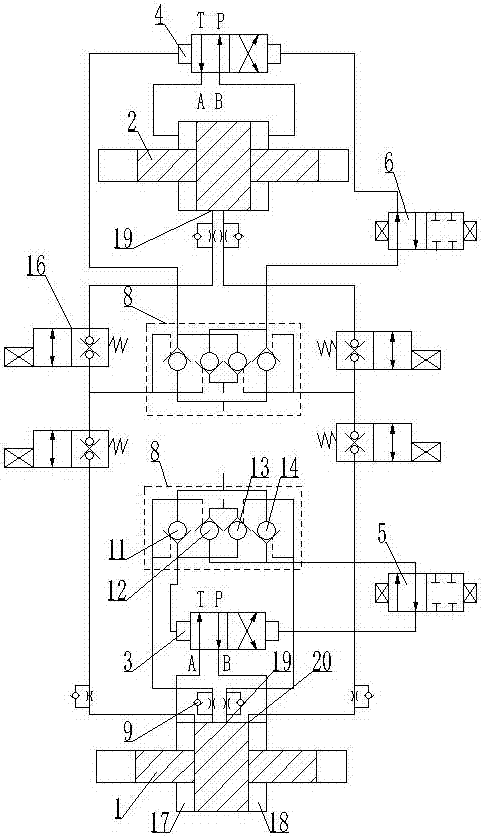

[0025] Such as image 3 As shown, in this embodiment, the two-way locking valve group and the first electromagnetic reversing valve in the second embodiment are replaced by electromagnetic ball valves, and the hydraulic control one-way valve group corresponding to the second booster cylinder can also be switched through the on-off of the electromagnetic ball valve. pilot control source. The action principle of this embodiment is the same as that of Embodiment 2 during pressurization operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com