Hydraulic oscillating machine

A full hydraulic and hydraulic cylinder technology, applied in the field of full hydraulic oscillators, can solve the problems of high failure rate, high cost, complex structure, etc., and achieve the effects of low cost, long service life and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

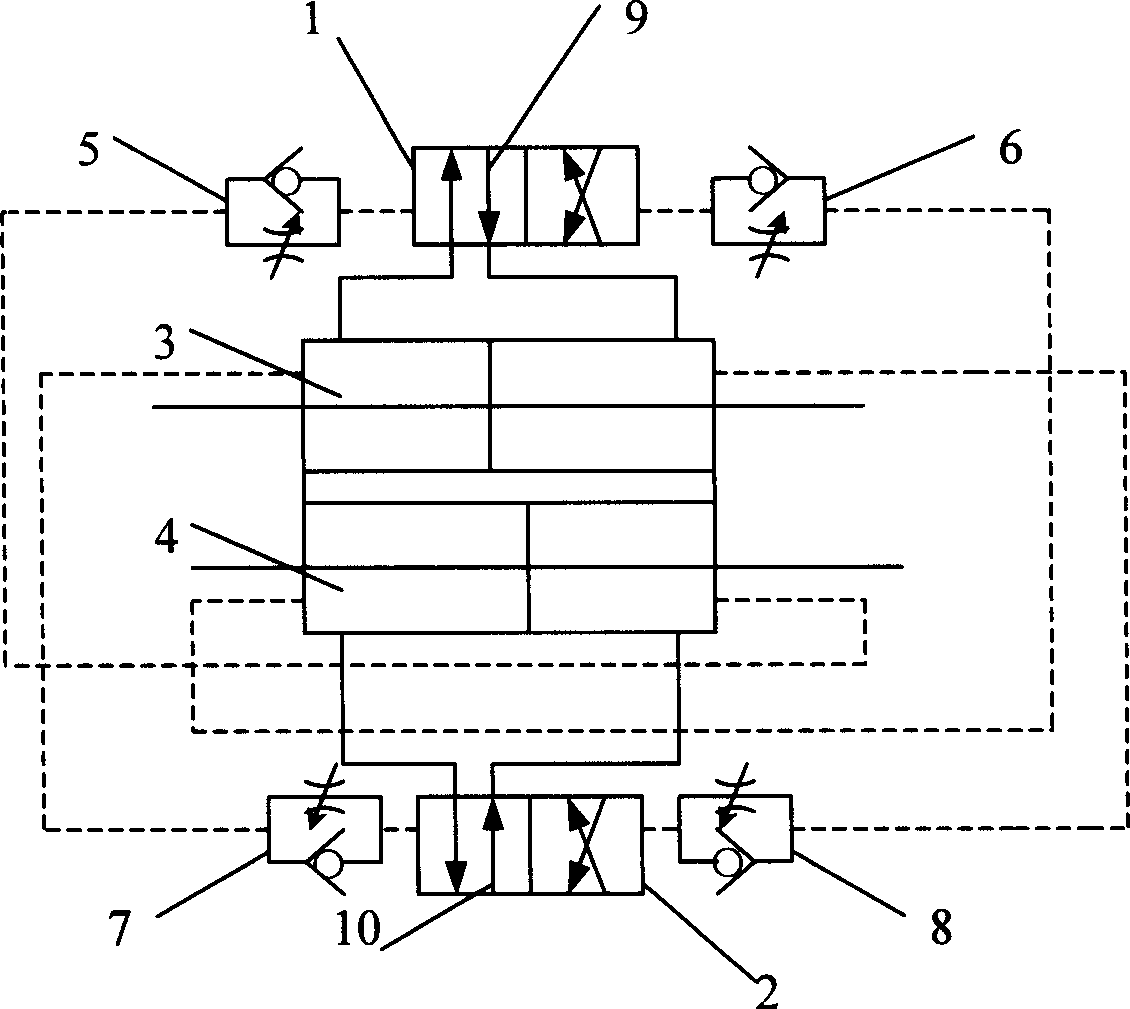

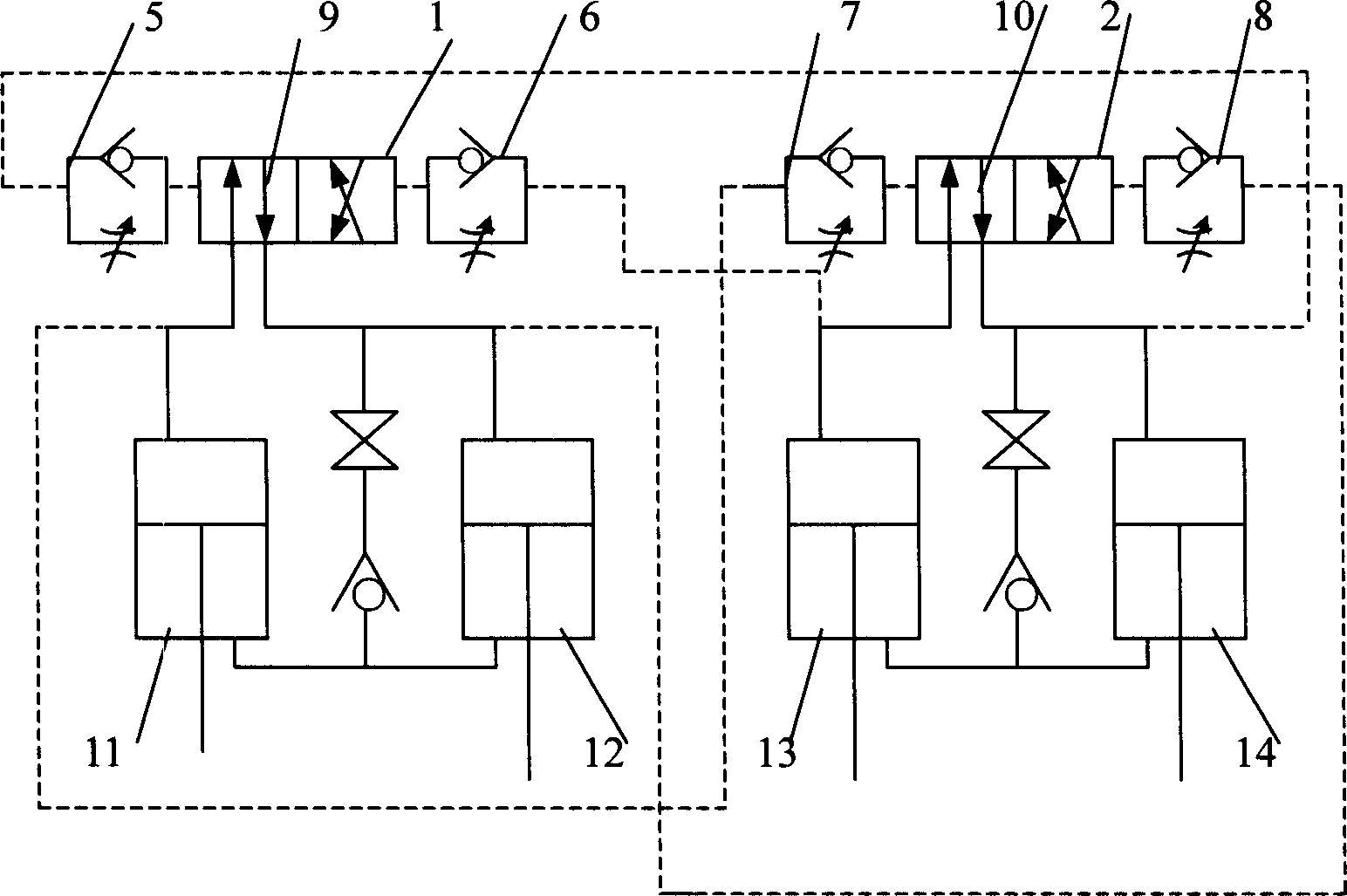

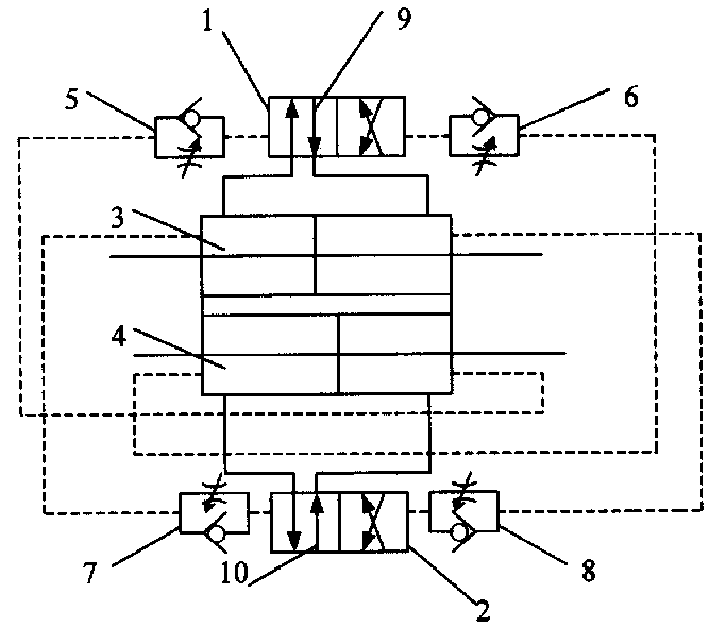

[0015] See figure 1 As shown, the full hydraulic oscillator of the present invention consists of two two-position four-way hydraulic reversing valves 1 and 2, two double-rod hydraulic cylinders 3 and 4, and four one-way throttle valves 5, 6, 7 and 8 constitute. It is improved for the hydraulic circuit, omitting the oil source part.

[0016] In the present invention, the four-way hydraulic reversing valve 1 controls the movement of the hydraulic cylinder 3 , and the four-way hydraulic reversing valve 2 controls the movement of the hydraulic cylinder 4 . The four one-way throttle valves are respectively connected to the control ports of the two hydraulic reversing valves, and the reversing time of the reversing valves is controlled by way of outlet throttling. The control ports at both ends of the four-way hydraulic reversing valve 1 are connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com