Hydraulic damping device

A technology of hydraulic damping and damping device, which is applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of noise, host vibration, and inability to meet the requirements of separate control and adjustment.

Inactive Publication Date: 2012-12-19

LANZHOU UNIVERSITY OF TECHNOLOGY

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally, the reversing movement of the spool of the hydraulic control spool valve is driven by hydraulic pressure, and the reset movement is driven by spring force. The movement has asymmetrical characteristics, and most of them are low-damping systems. Especially for large-flow hydraulic systems, the mass of the spool is large. , the inertia of the reversing movement is large. In order to make the spool reversing movement smooth and fast, at present, in engineering practice, the form of setting an oil return damping hole in the spool reversing oil circuit is often used to adjust the motion damping of the spool. The damping device has the advantages of simple structure and good craftsmanship, but it cannot satisfy the separate control and adjustment of the damping process of the positive and negative reversing movement of the slide valve hydraulic control valve core, which cannot fully match the asymmetry of the two-way movement of the valve core. The stability and rapidity of the spool changeover of the spool valve will deteriorate, which will easily cause overshoot fluctuations in the flow or pressure of the system, and cause problems such as vibration and noise of the main engine.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

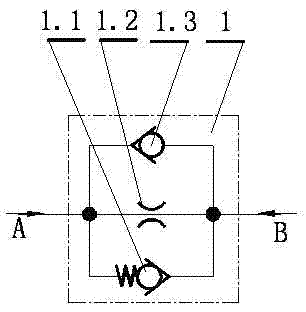

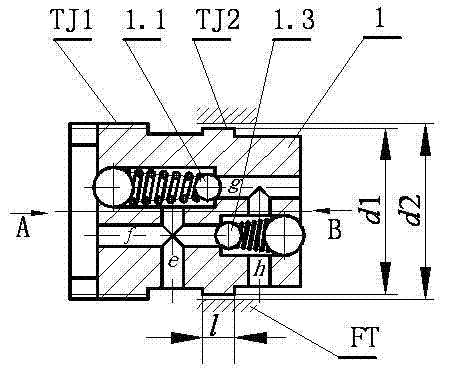

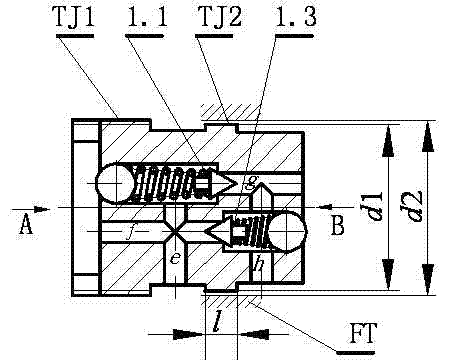

The invention relates to a hydraulic damping device for controlling and adjusting a dynamic process of a reversing motion of a valve core of a hydraulic controlled slide valve type hydraulic control valve. The device is of an integrated structure, and consists of a first one-way valve, a damping hole and a second one-way valve. An external screw thread is processed at the outer end of the device and the external screw thread can be inserted, screwed and installed in the hydraulic control valve. The first one-way valve, the damping hole and the second one-way valve are connected in parallel, and the first and second one-way valves are arranged opposite to each other. The hydraulic damping device is compact in structure and convenient to arrange, and the damping effects in positive and reverse motions of the valve core of the hydraulic controlled slide valve type hydraulic control valve can be respectively controlled and adjusted, and the valve core of the slide valve reveres stably and quickly.

Description

technical field [0001] The invention relates to a hydraulic damping device used for the control and adjustment of the dynamic process of the spool reversing movement of a hydraulic control slide valve type hydraulic control valve. Background technique Hydraulic control spool type hydraulic control valves are widely used in valve-controlled hydraulic systems. The dynamic process of the spool movement is related to the dynamic process of the main engine movement. Comfort plays a big role. Generally, the reversing movement of the spool of the hydraulic control spool valve is driven by hydraulic pressure, and the reset movement is driven by spring force. The movement has asymmetrical characteristics, and most of them are low-damping systems. Especially for large-flow hydraulic systems, the mass of the spool is large. , the inertia of the reversing movement is large. In order to make the spool reversing movement smooth and fast, at present, in engineering practice, the form of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F15B13/02

Inventor 李桂花王建森冀宏魏列江

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com