Forging loading robot

A robot and clamping mechanism technology, applied in the field of robots, can solve problems such as turning the head, easy to fall off, slow rotation, etc., to prevent machine damage, good safety performance, and ensure stable commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

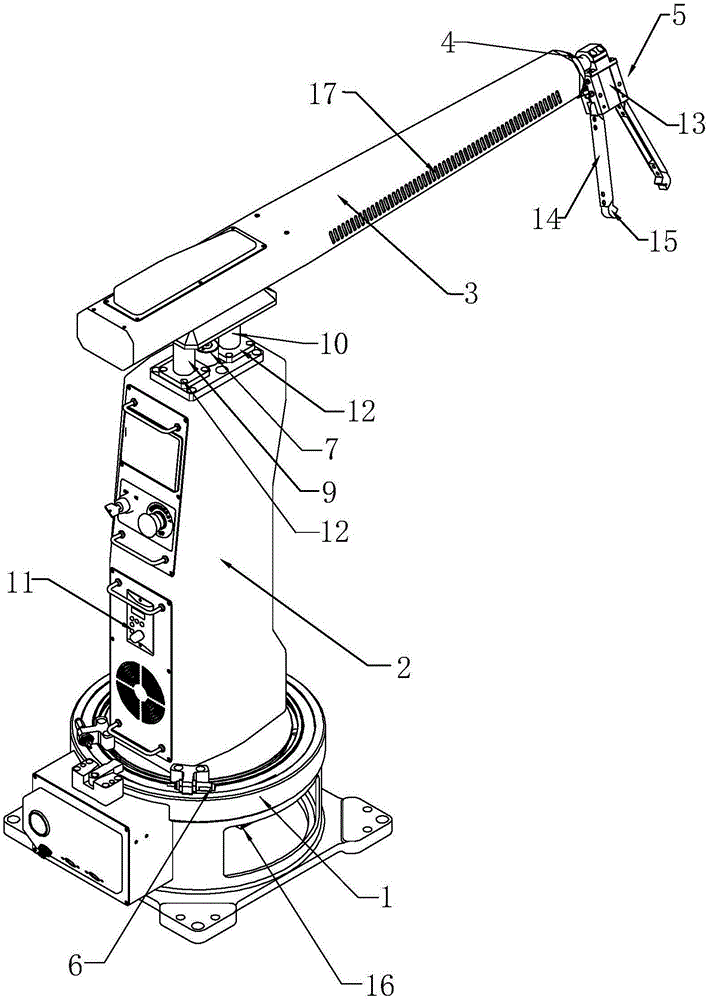

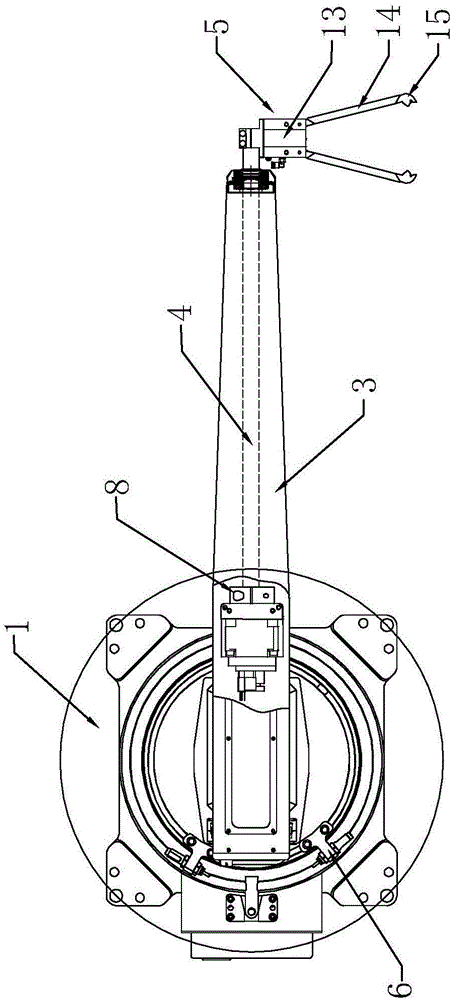

[0019] In this embodiment, the position when the rotating arm 2 is rotated to the intermediate position is defined as the 0° angular position of the rotating arm 2; the position when the lifting shaft 10 is at the lowest position is defined as the lower limit, that is, at 0 mm; The initial position of 4 is defined as the 0° angular position, that is, the position of the swing axis when the clamping mechanism 5 is vertically downward; the initial state of the double fork swing arm 14 is the open state, that is, the double fork swing arm 14 is vertical The face is at an angle of 30°.

[0020] Such as Figure 1 ~ Figure 2 The shown forging and feeding robot includes a rotating base 1, a rotating arm 2, a swing arm 3, a swing shaft 4, and a clamping mechanism 5. The rotating arm 2 is vertically installed on the rotating base 1 and can be moved with the rotating base 1 It rotates in the horizontal plane in a circumferential direction. Two hydraulic dampers 6 are also provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com