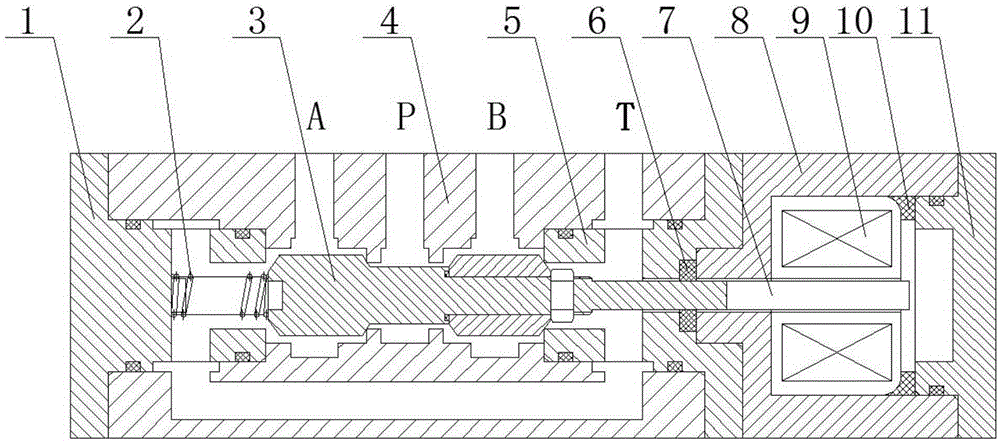

Double-cone type two-position four-way electromagnetic reversing valve

An electromagnetic reversing valve, two-position four-way technology, applied to multi-way valves, valve details, valve devices, etc., can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

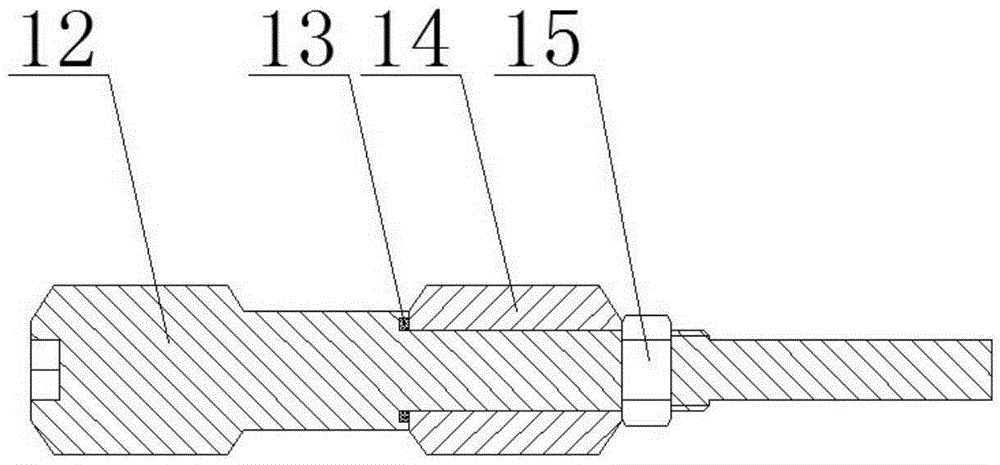

[0014] Such as Figure 1 to Figure 2 As shown in the embodiment, a double-cone two-position four-way electromagnetic directional valve includes a left valve seat 1, a return spring 2, a valve core 3, a valve body 4, a right valve seat 5, a dynamic seal 6, and a push rod 7. , Electromagnetic package housing 8, electromagnet 9, positioning ring 10, end cover 11, double-ended poppet valve core 12, sealing ring 13, double-ended poppet valve core 14, connecting nut 15, etc. When assembling, the double-ended cone valve core 12 passes through the inner cavity of the valve body 4 from the left side of the valve body 4, and the double-ended cone valve core 14 passes through the double-ended cone valve core 1 from the right side of the valve body 4. 12 on the right side of the guide rod, and press the sealing ring 13, the connecting nut 15 presses the double-ended poppet spool two 14, so that the double-ended poppet valve spool 12 and the double-ended poppet spool two 14 are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com